In today's fast-paced manufacturing landscape, the demand for efficient Heavy Roller Conveyor Assembly Line solutions is soaring. These systems are crucial for transporting heavy materials seamlessly. They enhance productivity and streamline operations, but selecting the right solution requires careful consideration.

Heavy Roller Conveyor Assembly Lines are not one-size-fits-all. Each industry has unique needs that must be addressed. For example, a food processing plant may require different specifications than an automotive assembly line. This diversity often leads to confusion and challenges in implementing an ideal solution.

Many businesses might overlook important features, such as load capacity and space optimization. Inadequate planning can result in a loss of efficiency. Achieving an ideal Heavy Roller Conveyor Assembly Line design involves continuous assessment and improvement. It's essential to stay informed about new technologies and available options to minimize potential pitfalls.

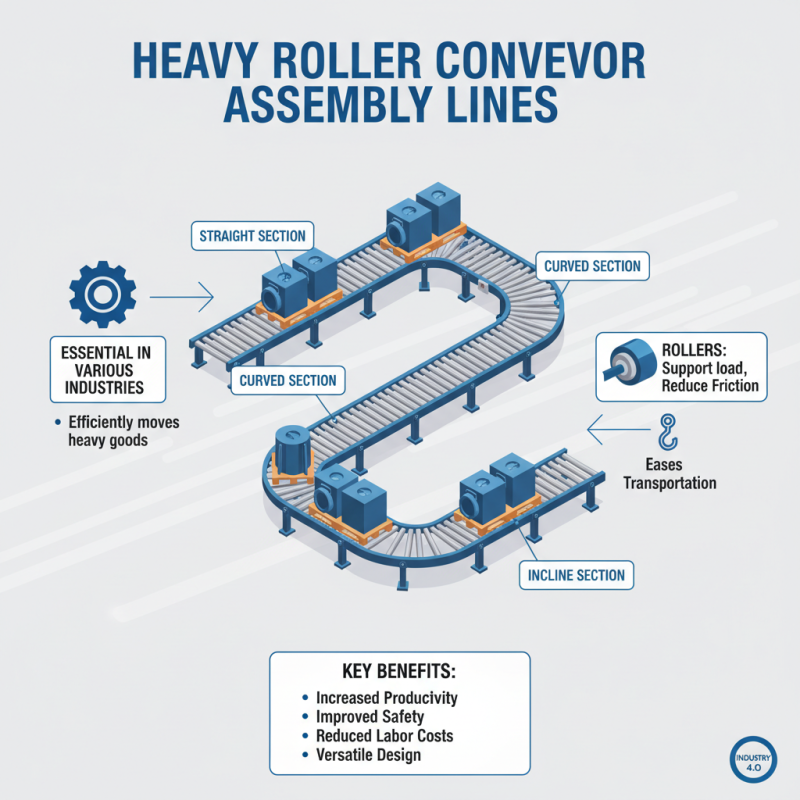

Heavy roller conveyor assembly lines are essential in various industries. These systems efficiently move heavy goods through different stages of production. They consist of rollers that support the load and reduce friction, making transportation easier. The design varies, but they typically include straight, curved, and incline sections.

When setting up these lines, careful planning is crucial. Miscalculations can lead to inefficiencies. For instance, improper spacing between rollers can slow down operations. It’s also vital to consider the load capacity. Overloading can damage the system. Maintenance is another aspect that requires attention. Regular checks can prevent costly breakdowns.

Ergonomics plays an important role too. Assembly line workers need comfortable setups to prevent fatigue. An uncomfortable workstation leads to decreased productivity. While automation is beneficial, it must not compromise safety. Balancing technology with human factors can improve overall workflow.

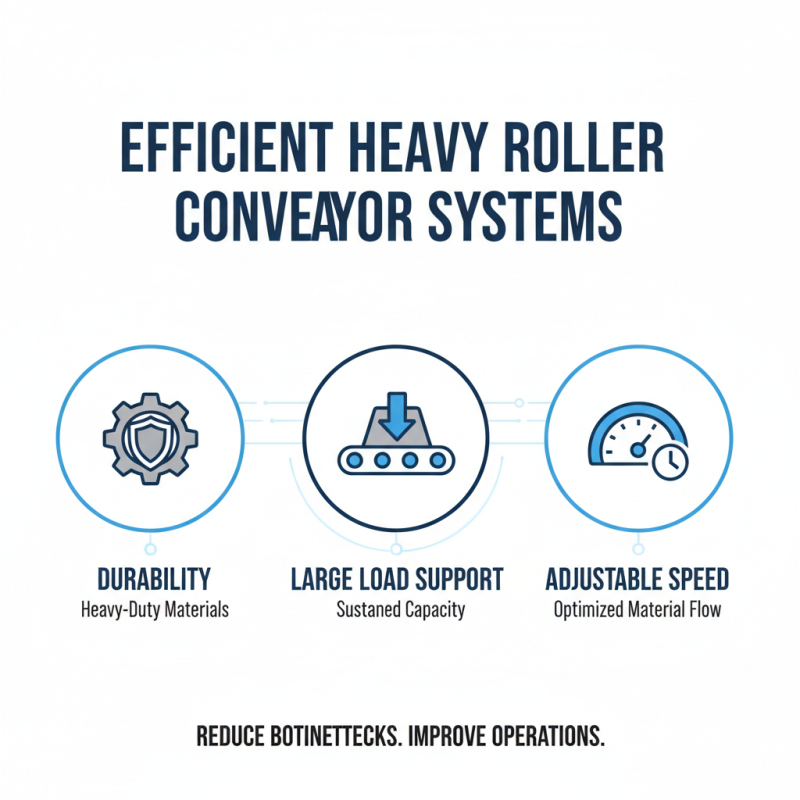

When designing efficient heavy roller conveyor systems, certain key features stand out. For instance, durability is crucial. Heavy-duty materials are essential for supporting large loads over time. Additionally, an adjustable speed feature helps optimize the flow of materials, reducing bottlenecks during operations.

Effective layout and spacing are vital. A well-planned conveyor line minimizes downtime. It allows smooth transitions and prevents jamming. Regular maintenance should not be overlooked, as wear and tear can impact performance. Finding the right balance between robust design and flexibility is challenging.

**Tip:** Look for modular designs. They offer adaptability to changing production needs. Evaluate your current workflows to identify areas needing improvement. A thorough assessment can lead to significant efficiency gains. Keep an eye on market trends to ensure that your systems remain competitive.

Heavy roller conveyors are essential in various industrial settings. They are designed to handle heavy loads efficiently. These conveyors ensure smooth material flow, minimizing downtime. Commonly utilized in manufacturing and warehousing, they play a critical role in logistics.

There are different types of heavy roller conveyors for diverse applications. For instance, gravity roller conveyors rely on incline or manual push. They are economical and simple to install. Powered roller conveyors, however, are ideal for heavy items. They provide consistent movement and can handle fluctuations in load.

Data indicates that the global conveyor systems market is projected to reach USD 9 billion by 2026. This growth reflects the increasing demand for automation in industries. Companies must reflect on their conveyor choices. Selecting the right conveyor type can significantly impact productivity. Upgrading an outdated system may reduce expenses and improve safety. But, initial investments can be a hurdle for some. A careful evaluation of needs is crucial in this evolving landscape.

Heavy roller conveyor solutions come with numerous benefits that enhance efficiency in assembly lines. These systems automate material handling, reducing manual labor. They offer high load capacity, making them ideal for heavy items. The smooth movement of products minimizes damage during transport. This reliability can lead to increased productivity.

Implementing heavy roller conveyors does come with challenges, though. Initial costs may be high for some companies. Additionally, maintenance is crucial; neglect can lead to breakdowns and delays. Employees may need training to operate and troubleshoot these systems effectively. Despite these hurdles, the advantages often outweigh the drawbacks.

Incorporating heavy roller conveyor systems can streamline operations. This integration can free up staff for more complex tasks. Careful planning is necessary to maximize efficiency. Observing the flow of goods can pinpoint areas for improvement. With the right approach, these solutions can significantly boost assembly line performance.

| Feature | Description | Benefits | Efficiency Improvement (%) |

|---|---|---|---|

| Load Capacity | Supports heavy items up to 1000 kg | Increased handling of heavy goods | 25% |

| Energy Efficiency | Lower power consumption | Reduced operational costs | 15% |

| Automation Integration | Compatible with various automated systems | Enhances production rates | 30% |

| Modular Design | Easily customizable layout | Flexibility for future upgrades | 20% |

| Maintenance Access | Easy access points for servicing | Reduced downtime | 10% |

When selecting a heavy roller conveyor assembly line, several key factors warrant consideration. Efficiency is paramount. Studies show that an optimized assembly line can improve productivity by over 30%. Thus, analyzing throughput levels is crucial. Companies must assess their specific requirements, including load capacity and speed.

Another essential element is durability. Heavy roller conveyors face significant wear and tear. According to industry reports, replacing components can lead to unexpected downtime, costing businesses up to $5,000 per hour. Investing in high-quality materials pays off in the long run. Additionally, flexibility in design is often overlooked. The ability to adapt to various product sizes increases overall efficiency.

Cost is always a concern. However, balancing initial expense with long-term savings is critical. There can be pitfalls in choosing cheaper options. They may lead to frequent breakdowns and higher maintenance costs. In contrast, a well-paired heavy roller conveyor system may appear expensive initially but can result in lower operational costs over its lifespan.

This bar chart provides a comparison of essential metrics for evaluating heavy roller conveyor assembly line solutions in 2026. The factors considered include load capacity, speed, durability, maintenance cost, and energy consumption.