The conveyor equipment industry is on the brink of a transformation. According to a recent report by MarketsandMarkets, the global conveyor systems market is expected to reach $9.5 billion by 2026. This growth is fueled by innovations in automation and efficiency. As industries seek more streamlined operations, conveyor equipment is at the forefront of change.

Experts emphasize the importance of adapting to these trends. John Reynolds, a leading authority in conveyor technology, noted, "The future lies in smart, interconnected conveyor systems." His insight reflects the industry's shift towards integrating IoT solutions and AI capabilities. These advancements promise to enhance productivity and minimize downtime.

However, the industry faces challenges. Not every company is ready to invest in cutting-edge technologies. Concerns over high initial costs and return on investment linger. This resistance may slow down the adoption of critical innovations. Despite these hurdles, the push for efficient conveyor equipment continues, signaling a pivotal moment for industrial operations.

The conveyor industry is on the brink of significant transformation in 2026, fueled by emerging technologies. Innovations like artificial intelligence and IoT are dramatically reshaping conveyor systems. These advancements enhance efficiency and reduce downtime. According to a recent industry report, AI implementations can boost operational efficiency by 25%. Companies are adopting smart systems that monitor performance in real time.

Automation is another vital trend. Many industries are shifting to automated solutions for material handling. This transition can lead to a 30% reduction in labor costs. However, the integration of these technologies often comes with challenges. Organizations must address the skills gap among workers, as new systems require different expertise.

**Tip:** Regular training for employees can ease the transition to advanced systems. Emphasizing continuous learning is essential.

Environmental sustainability is also a focal point. Many companies aim to reduce their carbon footprints. Using energy-efficient conveyor systems can lower energy consumption by up to 40%. However, the initial investment may be a hurdle for smaller firms. Evaluating long-term benefits versus short-term costs is crucial.

**Tip:** Start with pilot projects to test new technologies before full implementation. This approach minimizes risks involved.

| Trend | Description | Impact on Industry | Estimated Adoption Rate (%) |

|---|---|---|---|

| AI Integration | Utilizing AI for predictive maintenance and automated decision-making in conveyor systems. | Enhances efficiency and reduces downtime significantly. | 75% |

| IoT Connectivity | Integration of Internet of Things for real-time monitoring and data collection. | Improves tracking and operational transparency. | 70% |

| Modular Designs | Flexible and scalable conveyor systems designed for easy reconfiguration. | Enhances adaptability to changing production needs. | 65% |

| Sustainability Practices | Focus on eco-friendly materials and energy-efficient systems. | Lower environmental impact and compliance with regulations. | 80% |

| Autonomous Systems | Use of robotics and automation for transportation and sorting tasks. | Increases productivity and reduces labor costs. | 60% |

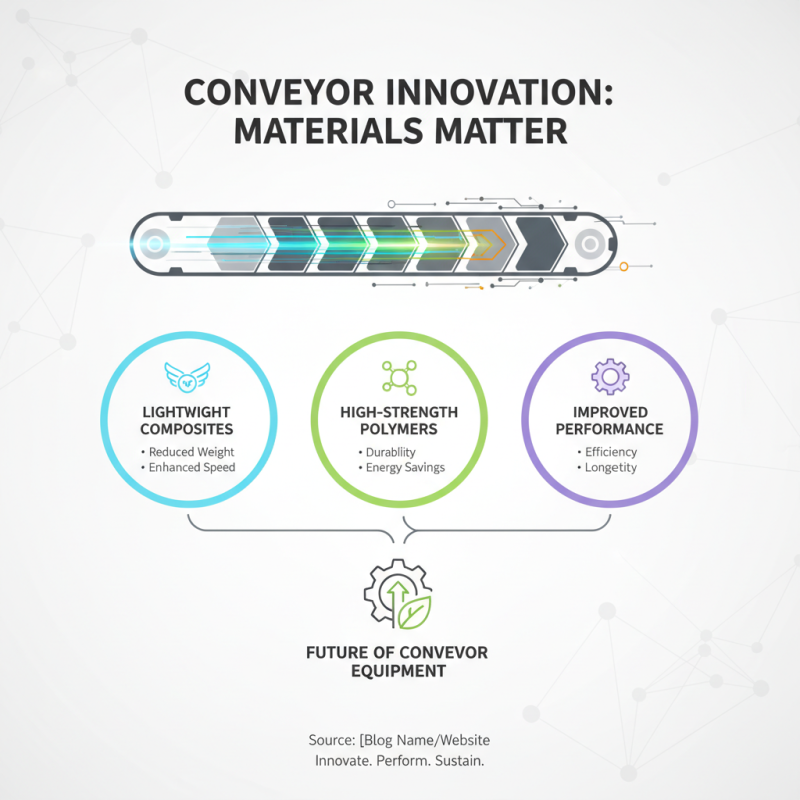

Innovative materials are taking center stage in the evolution of conveyor equipment. These new materials promise improved performance and efficiency. Lightweight composites and high-strength polymers are leading the charge. They reduce the overall weight of conveyor systems, which can enhance speed and energy savings.

However, the transition to these advanced materials is not without challenges. Many companies grapple with the durability of these new options. Some materials may not withstand harsh industrial environments as well as traditional metal. This can lead to unexpected downtime and maintenance issues. Organizations need to test these materials rigorously before full-scale implementation.

Moreover, the supply chain for these innovative materials can also be a hurdle. Sourcing alternatives may require new partnerships and logistics strategies. Without careful planning, companies may face delays and increased costs. Risks exist, but the potential for superior performance makes this exploration worthwhile. Balancing innovation and reliability remains a critical focus for industries looking to enhance their conveyor systems.

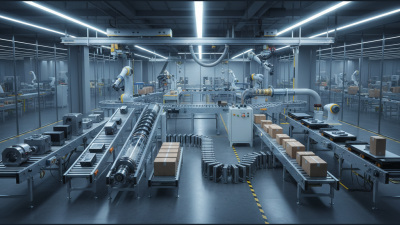

The landscape of conveyor operations is changing. Automation and robotics are at the forefront of this shift. These technologies enhance efficiency significantly. They also reduce manual labor, posing challenges for workers. Facilities must adapt to these changes. Training programs are vital for workers to transition smoothly into new roles.

Implementing robotic systems can optimize workflows. Robots can maneuver in tight spaces where humans might struggle. They handle tasks like sorting and packaging. This precision minimizes errors, increasing productivity. Yet, reliance on automation can create concerns about job stability. Companies must ensure a balance between technology and human input.

Moreover, maintenance of automated systems requires skilled personnel. As operations become more complex, the need for specialized technicians grows. Some businesses might overlook this, focusing solely on technological upgrades. Ignoring the human element could lead to operational failures. Each advancement demands thoughtful consideration of its impact on the workforce.

The shift towards sustainability in conveyor equipment design is gaining momentum. Industries are examining their environmental footprints and seeking eco-friendly solutions. Lightweight materials are being adopted to reduce energy consumption. This change not only cuts costs but also minimizes resource use.

Innovative designs focus on energy efficiency. Many conveyor systems now incorporate regenerative drives. This technology captures energy during operation and feeds it back into the system. Some companies are exploring renewable energy sources to power their equipment. However, challenges remain in implementing these solutions effectively.

While the trend is promising, it raises questions about recycling. The disposal of outdated equipment often leads to waste. Manufacturers must consider end-of-life strategies for their products. Developing fully recyclable conveyors could be a significant step forward. The path to sustainability is not without obstacles, but the potential rewards are substantial.

The integration of the Internet of Things (IoT) in conveyor systems is transforming manufacturing and logistics. Smart conveyor monitoring allows real-time data collection. Sensors track conveyor performance, errors, and maintenance needs. According to a recent industry report, companies that utilize IoT in their operations can see a potential increase in efficiency by up to 30%. This is a significant gain for industries aiming to reduce downtime.

Tips: Start small. Implement IoT sensors on one conveyor line before scaling up. Monitor data closely for patterns and issues. This approach minimizes risks while learning the system's behaviors.

Challenges exist. Not all companies fully grasp how to leverage IoT. Data overload can make decision-making tough. Systems may require adjustments to work seamlessly together. Ensuring proper staff training is vital for success. In fact, a survey found that 45% of companies struggle with staff understanding of new technologies.

Tips: Invest in training programs for your team. Regular workshops can help staff adapt to new systems effectively. Engage your workforce to encourage a culture of continuous improvement and innovation.

This chart illustrates the projected investment growth in IoT for smart conveyor systems from 2023 to 2026. As industries increasingly integrate IoT technologies, significant growth is expected, reflecting the transformation in conveyor equipment management.