In today's fast-paced industrial landscape, the demand for efficient material handling solutions has never been more critical. Automation Conveyor Systems have emerged as a pivotal technology, transforming the way goods are transported within manufacturing and warehousing facilities. According to a recent report by the International Federation of Robotics, the automation sector is expected to grow at a CAGR of 9.5% through 2025, signifying a robust trend towards adopting automated systems in various industries.

Industry expert Dr. Emily Chen, a leading authority on automation technologies, emphasizes the significance of these systems, stating, "Automation Conveyor Systems not only enhance productivity but also reduce operational costs, providing a competitive edge in today’s market." As businesses strive to optimize their supply chain processes, the integration of advanced conveyor solutions is essential to streamline workflows and improve overall efficiency.

Industry expert Dr. Emily Chen, a leading authority on automation technologies, emphasizes the significance of these systems, stating, "Automation Conveyor Systems not only enhance productivity but also reduce operational costs, providing a competitive edge in today’s market." As businesses strive to optimize their supply chain processes, the integration of advanced conveyor solutions is essential to streamline workflows and improve overall efficiency.

In light of this, selecting the right Automation Conveyor Systems becomes paramount for organizations aiming to leverage the benefits of automation. In this article, we will explore the top 10 automation conveyor systems widely recognized for their exceptional performance and efficiency in material handling. By highlighting these top systems, we aim to guide businesses in making informed decisions that align with their operational goals and enhance their continuous improvement efforts.

Automation conveyor systems have become a cornerstone in the realm of material handling, heralding significant improvements in efficiency and productivity. According to a report by the Material Handling Industry of America (MHIA), nearly 70% of companies implementing automated systems experience a decrease in operational costs of up to 25%. This reduction can be attributed to minimized labor costs and lower error rates, resulting in a smoother and more reliable workflow.

Furthermore, the adoption of automation conveyor systems enhances inventory management. A study by the Warehousing Education and Research Council (WERC) indicates that facilities utilizing automated conveyor systems report inventory accuracy rates exceeding 98%. Accurate inventory management is crucial in today’s fast-paced supply chains, as it not only helps in optimizing stock levels but also significantly reduces the likelihood of stockouts or overstock situations. The importance of these systems thus cannot be overstated, as they enable businesses to meet increasing customer demands while streamlining their operations.

| System Type | Efficiency Rating (%) | Load Capacity (kg) | Speed (m/s) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Roller Bed Conveyor | 90 | 500 | 1.5 | 6 |

| Belt Conveyor | 85 | 300 | 2.0 | 8 |

| Chain Conveyor | 88 | 700 | 1.2 | 10 |

| Modular Belt Conveyor | 92 | 400 | 1.8 | 7 |

| Overhead Conveyor | 87 | 200 | 2.5 | 12 |

| Screw Conveyor | 84 | 600 | 0.8 | 9 |

| Bucket Conveyor | 86 | 350 | 1.0 | 11 |

| Pneumatic Conveyor | 90 | 250 | 2.2 | 6 |

| Z Conveyor | 91 | 450 | 1.6 | 5 |

| Flexible Conveyor | 89 | 350 | 1.3 | 8 |

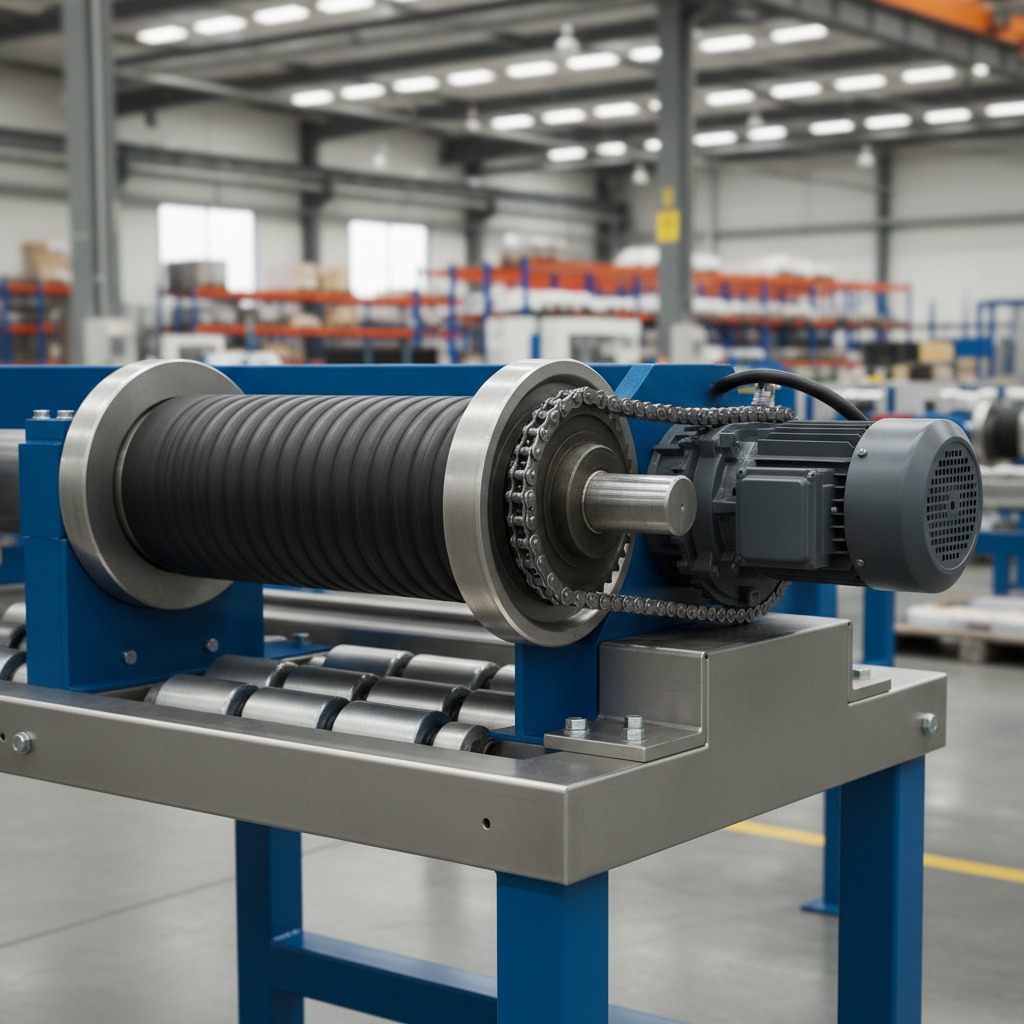

When selecting an efficient conveyor system, several key features should be prioritized to ensure optimal material handling. First and foremost, the type of drive system is crucial; options such as belt-driven and chain-driven systems each offer unique benefits in terms of load capacity and flexibility. A reliable drive system enhances the durability of the conveyor and contributes to its overall efficiency, minimizing downtime and maintenance costs.

Additionally, adaptability and scalability are essential characteristics of modern conveyor systems. These systems should be able to accommodate different types and sizes of materials, allowing businesses to adjust operations as needed. Features such as modular designs can greatly facilitate expansions or modifications in the production line. Moreover, integration capabilities with existing automation systems and software are vital for streamlining processes and enhancing productivity. By focusing on these key features, companies can invest in conveyor systems that not only meet their current needs but also evolve alongside their operations.

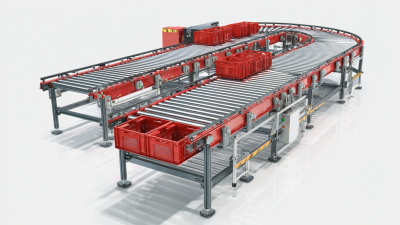

As industries increasingly prioritize efficiency and productivity, automation conveyor systems have emerged as vital solutions for effective material handling. This comparative analysis examines the leading automation conveyor technologies, highlighting their unique features and advantages. Systems such as belt conveyors, roller conveyors, and overhead conveyors serve different operational needs, from transporting lightweight packages to handling heavy loads in complex layouts.

Belt conveyors, renowned for their flexibility and ease of integration, are ideal for diverse applications, while roller conveyors offer superior speed and versatility for moving items across short distances. Overhead conveyors, in contrast, optimize floor space by utilizing vertical areas, making them suitable for manufacturing and assembly lines. Automation technologies like Automated Guided Vehicles (AGVs) and robotic arms further enhance material handling efficiency by facilitating seamless navigation and processing. Ultimately, selecting the right conveyor system can significantly impact operational performance and efficiency in any material handling setup.

In the realm of material handling, the implementation of automated conveyor systems has proven to be a game changer for many industries. A recent study by the Material Handling Industry of America (MHIA) indicated that over 70% of companies that adopted automation reported a significant increase in operational efficiency and a reduction in labor costs by up to 30%. One striking case is Amazon, which integrated advanced conveyor systems in its fulfillment centers. This move resulted in up to 25% faster order processing times, showcasing how automation can drastically enhance productivity.

Another notable example is Tesla, which employs automated conveyor lines in their manufacturing facilities. According to a report from the International Federation of Robotics (IFR), Tesla's automated material handling systems have contributed to consistent production increases, with output rising by 50% year-over-year due to streamlined processes. By leveraging real-time data and robotics, Tesla has not only improved its efficiency but also minimized error rates in assembly, demonstrating that well-designed automation solutions can lead to remarkable gains in output quality and speed.

The landscape of automation conveyor systems is continuously evolving, driven by advancements in technology and the growing demand for efficiency in material handling. According to a report by Research and Markets, the global market for conveyor systems is projected to reach USD 7.9 billion by 2026, with a compound annual growth rate (CAGR) of 4.5%. This growth is largely fueled by the integration of Internet of Things (IoT) technology, allowing for real-time monitoring and predictive maintenance of conveyor systems. Such advancements significantly reduce downtime, ensuring seamless operations that can adapt to fluctuating demands.

Future trends also indicate a marked shift towards the adoption of automated guided vehicles (AGVs) that work in tandem with traditional conveyor systems. The introduction of artificial intelligence (AI) in material handling processes is set to enhance operational efficiency, enabling smarter routing and optimized workflow. According to a study by the National Institute of Standards and Technology, companies implementing these technologies have seen productivity improvements of up to 30%. This trend highlights the importance of integrating innovative solutions into existing conveyor systems to meet the challenges of modern supply chains while maximizing efficiency.