The manufacturing industry is constantly evolving, and one of the pivotal components driving efficiency and productivity is the implementation of Assembly Conveyor Systems. According to a report by the American Manufacturing Association, approximately 70% of manufacturers have adopted conveyor systems to streamline their production processes, thus enhancing their overall operational efficiency. These systems not only facilitate the smooth movement of materials but also significantly reduce labor costs and minimize cycle times, which is crucial in today’s competitive market.

Expert insights further emphasize the importance of Assembly Conveyor Systems in modern manufacturing. Dr. Jane Smith, a renowned industrial engineer and conveyor systems specialist, states, "Integrating efficient assembly conveyor systems is no longer an option; it’s a necessity for those looking to optimize their production lines." This sentiment reflects a broader industry trend where businesses are investing in technology that supports agility and scalability in their operations. As manufacturers strive to meet the ever-increasing demands of consumers, the reliance on Assembly Conveyor Systems will undoubtedly expand, highlighting their essential role in the future of manufacturing processes.

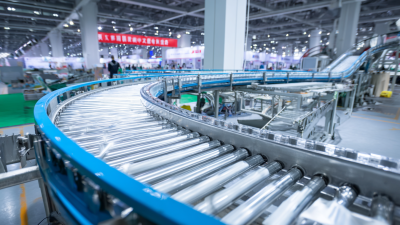

Assembly conveyor systems play a crucial role in manufacturing by significantly streamlining production processes. These systems facilitate the smooth movement of products from one assembly station to another, minimizing delays often caused by manual transportation. By optimizing the flow of materials, companies can enhance their operational efficiency, reduce bottlenecks, and ultimately increase overall productivity. This seamless integration allows for a more organized workspace where workers can focus on their tasks without interruptions, leading to improved output quality.

Moreover, assembly conveyor systems contribute to better workforce management. With the elimination of repetitive manual tasks, employees can dedicate more time and attention to complex assembly processes that require skill and precision. This not only boosts worker morale but also fosters a safer working environment by reducing the risk of injuries associated with heavy lifting. Furthermore, the consistent pace of assembly conveyor systems aids in maintaining a steady workflow, making it easier to meet production deadlines and adapt to fluctuations in demand. The adaptability of these systems ensures that manufacturers can quickly respond to changing market needs without sacrificing efficiency.

In the fast-paced world of manufacturing, efficiency is paramount. One of the most significant advantages of utilizing assembly conveyor systems is their ability to drastically reduce cycle times. By automating the material handling processes, manufacturers can streamline the flow of components and finished products, ensuring that production lines operate smoothly and effectively. This increased speed not only allows for a quicker turnaround but also improves overall productivity, enabling companies to meet higher demand without compromising quality.

Tips for maximizing the efficiency of conveyor systems include conducting regular maintenance checks to prevent unexpected downtime, and training employees on best practices for using the systems to minimize errors. Additionally, optimizing the layout of the conveyor system can lead to a more effective flow of materials. Consider integrating different conveyor types to accommodate various products and reduce bottlenecks in the assembly process.

Another important aspect to consider is the seamless integration of conveyor systems with existing technology. This can create a more cohesive production environment, allowing for real-time tracking of materials and enhancing communication across departments. By adopting these strategies, manufacturers can fully leverage the potential of assembly conveyor systems, leading to improved efficiency and reduced cycle times in their operations.

Using assembly conveyor systems in manufacturing not only streamlines production processes but also significantly enhances product quality through consistent handling methods. The precise nature of these conveyor systems ensures that products move along a predefined path without unexpected interruptions or variations. This stability is crucial in maintaining uniformity in the production line, confirming that each product receives equal attention and care during assembly, which ultimately leads to a higher quality end product.

Moreover, consistent handling minimizes the risk of damage to products as they are transported. Unlike manual handling, which can be prone to human error, conveyor systems operate at a steady pace and reduce the chances of mishandling or dropping items. This reliability allows for better adherence to quality standards, as every product is treated with the same degree of gentleness and care throughout the assembly process. As a result, manufacturers can achieve tighter tolerances and meet stringent quality specifications, enhancing customer satisfaction and trust in the final products.

| Benefit | Description | Impact on Product Quality |

|---|---|---|

| Increased Efficiency | Assembly conveyor systems streamline production processes. | Reduced bottlenecks lead to uniform product quality. |

| Consistent Handling | Uniform movement of products ensures less damage. | Minimized defects and enhanced durability. |

| Reduced Labor Costs | Automation lowers dependency on manual labor. | Maintains consistent product assembly standards. |

| Enhanced Tracking | Improved visibility in the production process. | Easier identification of quality issues early on. |

| Flexibility | Systems can adapt to different products easily. | Consistent quality across varying product ranges. |

| Improved Safety | Reduces manual handling risks. | Fewer accidents ensure steady production of quality products. |

| Shorter Lead Times | Faster movement from assembly to finished product. | Quicker time to market enhances overall quality assurance. |

| Quality Control Integration | Facilitates real-time quality inspections during assembly. | Immediate feedback loop enhances product integrity. |

| Reduced Waste | Optimized use of materials throughout the process. | Lower waste improves overall product efficiency. |

| Data Collection | Automated systems collect production data for analysis. | Data-driven decisions lead to improved quality outcomes. |

Assembly conveyor systems play a crucial role in enhancing the flexibility and customization of manufacturing processes. By allowing manufacturers to design tailored workflows that adapt to specific production needs, these systems facilitate a seamless integration of various components. This adaptability enables businesses to efficiently switch between different product lines or modify assembly processes without extensive downtime, thus responding quickly to market demands and customer preferences.

Moreover, the modular nature of assembly conveyor systems permits modifications and expansions as manufacturing needs evolve. Manufacturers can easily incorporate new technology, upgrade existing components, or reconfigure layouts without significant disruptions to overall operations. This flexibility not only enhances productivity but also fosters innovation, allowing companies to explore diverse manufacturing strategies. As a result, assembly conveyor systems support a more dynamic manufacturing environment where customization becomes a competitive advantage, enabling companies to deliver unique products that cater to specific consumer requirements.

Assembly conveyor systems play a crucial role in enhancing worker safety and ergonomics on assembly lines. According to a report from the Occupational Safety and Health Administration (OSHA), approximately 2.9 million nonfatal workplace injuries were reported in the United States in a single year, many of which are linked to poor ergonomic practices. By implementing assembly conveyor systems, manufacturers can optimize workflows, reducing the need for excessive bending, lifting, and reaching. This reduction in manual handling not only minimizes the risk of injury but also promotes a more comfortable working environment, leading to higher employee satisfaction and retention rates.

Incorporating ergonomic principles into assembly lines through conveyor systems can lead to significant productivity gains. A study published in the Journal of Occupational and Environmental Medicine indicates that companies that prioritize ergonomics can see productivity improvements by up to 25%. This increase can be attributed to reduced fatigue levels among workers, allowing them to focus on quality and speed rather than coping with discomfort. Conveyor systems facilitate this by allowing for adjustable heights and customizable workstations, providing workers with a tailored experience to suit their physical needs.

**Tips:** To further improve worker safety, ensure regular maintenance checks on conveyor systems to decrease the likelihood of breakdowns, which can lead to accidents. Training workers on proper lifting techniques and ergonomic practices can also enhance their safety and comfort. Lastly, involving employees in the design process of their work environment can foster a sense of ownership and improve adherence to safety protocols.

This chart illustrates the key benefits of utilizing assembly conveyor systems in manufacturing environments, highlighting improved worker safety, efficiency, and production reliability.