In the fast-paced world of manufacturing, optimizing efficiency is crucial. Assembly Conveyor Systems play a vital role in this process. These systems streamline production, ensuring that each component moves smoothly from one station to the next. They reduce manual handling and enhance productivity.

However, not all assembly conveyor systems are created equal. Some may fall short in flexibility or speed. A system that excels in one area may struggle in another. Evaluating options is essential. Factors like layout, product type, and worker interaction must be considered. Choosing the right assembly conveyor system requires careful reflection and planning.

Investing in a reliable assembly conveyor system can yield significant returns. Improved workflow leads to faster production cycles. Yet, businesses must remain vigilant. Regular maintenance and updates are key to long-term success. An outdated system can hinder progress, so continuous assessment is necessary. Ultimately, the right system makes a difference.

Assembly conveyor systems play a vital role in modern production environments. Different types exist to accommodate various manufacturing needs. For example, belt conveyors are widely used due to their versatility. A report by the Conveyor Equipment Manufacturers Association shows that belt conveyors make up about 40% of the market share. They are ideal for transporting bulk materials and products efficiently.

In contrast, modular conveyor systems offer flexibility and easy customization. They can adapt to changing production lines without extensive modifications. Data indicates that these systems can reduce setup time by up to 30%. However, some may find the initial investment challenging. This often leads to indecision in choosing between cost and efficiency.

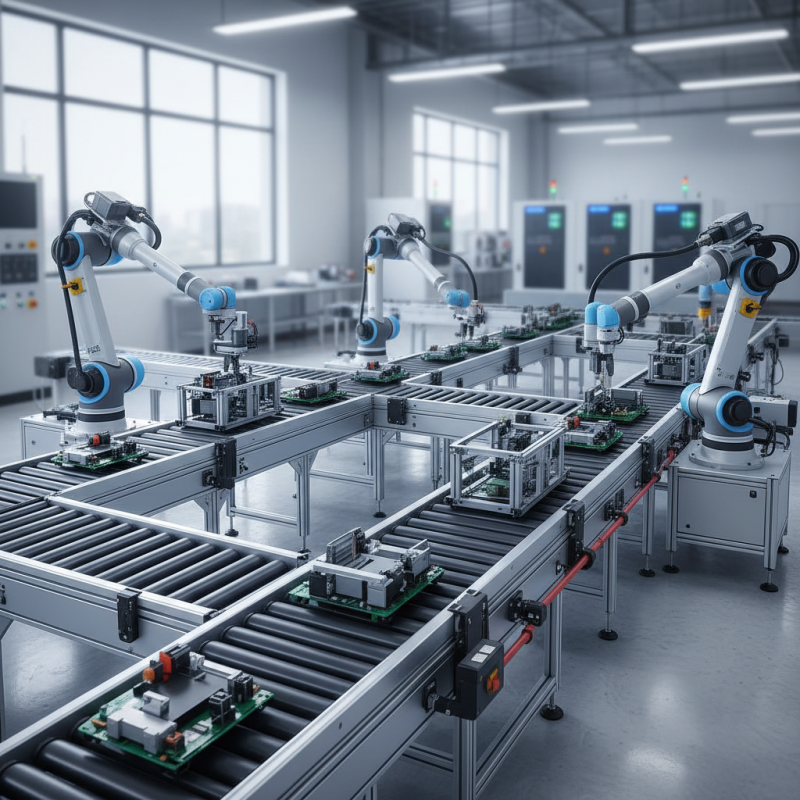

Additionally, automated guided vehicles (AGVs) are gaining traction in assembly lines. They provide a unique solution for dynamic environments. Statistics reveal that AGVs can enhance production efficiency by 20% compared to traditional systems. Nevertheless, the complexity of integration can be a concern. Companies must weigh the potential benefits against the need for skilled personnel for operation and maintenance.

| Type of Conveyor | Ideal Use Cases | Max Load Capacity (lbs) | Speed (ft/min) | Key Features |

|---|---|---|---|---|

| Belt Conveyor | Assembly lines, packaging | 200 | 60 | Versatile, easy to maintain |

| Roller Conveyor | Heavy loads, warehouse | 500 | 30 | Robust, low friction |

| Overhead Conveyor | Clothing, automotive assembly | 300 | 40 | Space-saving, customizable |

| Modular Conveyor | Flexible environments | 250 | 50 | Customizable layouts, easy installation |

| Chain Conveyor | Heavy materials, food processing | 1200 | 20 | Durable, resistant to harsh environments |

When considering high-efficiency conveyor systems, certain key features stand out. The material of the conveyor belt is essential. Materials should provide durability and support for the weight being transported. For example, metal and plastic are common choices. They have different applications based on production needs. Additionally, the width of the conveyor can affect its capacity. A wider belt allows for more items to be moved simultaneously.

Flexibility is another critical aspect. Modular designs help adapt the conveyor system to changes in production lines. A system that can easily adjust to different configurations saves time during transitions. Maintenance features are crucial too. A conveyor system should allow for easy access to components for repairs. Timely maintenance can extend the life of the system.

Tips: Look for systems with adjustable speeds. This feature allows control over the flow of goods. Also, consider energy consumption. An efficient conveyor system helps reduce operating costs. Regularly evaluate the layout to enhance workflow. Ensure the system aligns with your production goals.

Automated assembly conveyor systems have gained prominence for their ability to enhance production efficiency. These systems streamline workflows, reduce manual labor, and improve accuracy in various industries. According to a report by the International Society of Automation, businesses utilizing automated systems can increase productivity by 20-30%. This significant boost demonstrates the effectiveness of such solutions.

Furthermore, automated conveyors reduce the time spent on repetitive tasks. Workers are freed up for more complex responsibilities. A study by Manufacturing Tomorrow showcased that companies reported a 15% decrease in operational costs post-implementation. However, transitioning to automation requires careful planning. Integrating new systems with existing workflows can be challenging.

Moreover, automated systems can improve product quality. Consistent handling minimizes the risk of errors and defects. Yet, organizations must not overlook the initial costs of these systems. Infrastructure changes and training can strain budgets. Industries must consider these factors while weighing the benefits of automated assembly conveyors.

Choosing the right conveyor material is crucial for durability and performance in assembly conveyor systems. Various materials, such as steel, plastic, and rubber, have their unique benefits and drawbacks.

Steel is known for its strength and longevity but can be heavy and prone to rust. In contrast, plastic offers lightweight flexibility but might wear out faster under heavy loads.

According to a report from the Conveyor Equipment Manufacturers Association, over 40% of production downtime is linked to conveyor failure. This emphasizes the need for selecting robust materials that minimize maintenance. If your conveyor system often breaks down, it may lead to increased costs and wasted time.

Rubber, while providing excellent grip, can degrade under certain chemical exposures, affecting its durability.

It’s vital to consider the environment where the conveyor operates. For example, a humid or corrosive atmosphere could reduce the lifespan of certain materials. Customizing your selection based on specific operational needs may yield better results. Reassessing long-term material performance is essential, as initial costs do not always reflect future expenses related to repairs and replacements.

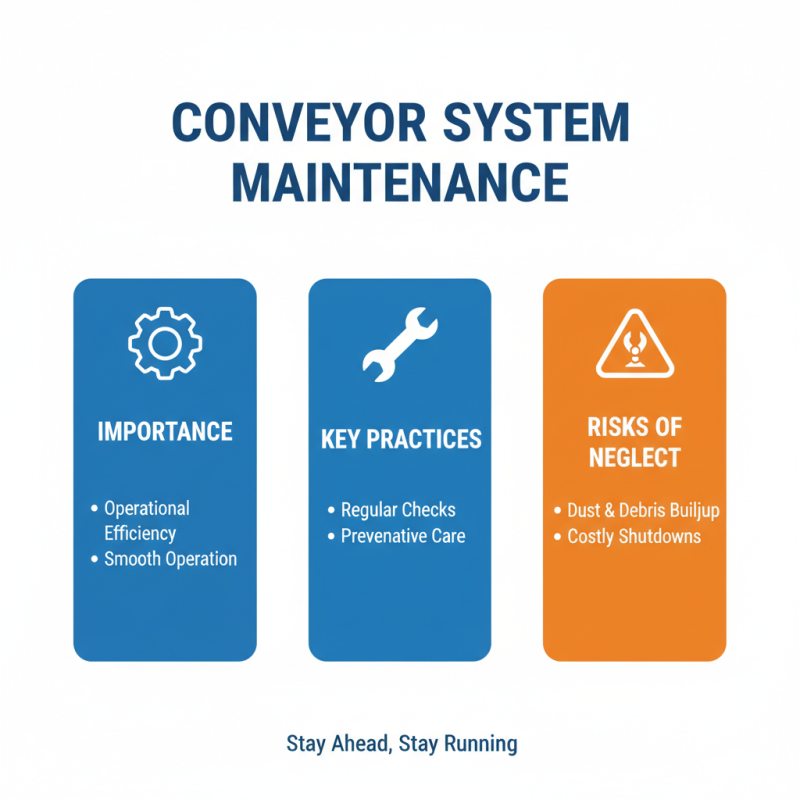

Maintaining conveyor systems is crucial for operational efficiency. Regular checks ensure smooth running. Without proper care, issues can arise unexpectedly. Dust and debris can build up, causing wear and tear. This leads to costly shutdowns.

Tips for maintenance: Clean the conveyor regularly. Use appropriate cleaning agents. Tighten any loose parts to enhance stability. Inspect belts or chains often. Listen for unusual sounds; they might signal problems.

Over time, components may wear more than anticipated. It's vital to keep a close eye on these parts. Replace them before they fail completely. Schedule maintenance during off-peak hours. This could minimize disruptions. Ignoring small issues can lead to bigger problems later. Everyone in the team should be trained to recognize potential trouble.