In the ever-evolving landscape of manufacturing, the efficiency of production lines is paramount to achieving optimal operation and maximizing output. A pivotal component in this equation is the use of Assembly Conveyor Systems, which streamline the movement of materials and components throughout the production process. These systems are designed to enhance workflow, reduce bottlenecks, and facilitate seamless integration across various stages of assembly, making them an indispensable asset in modern manufacturing environments.

As industries continue to seek ways to enhance productivity, the selection of the right Assembly Conveyor Systems plays a crucial role. With numerous configurations and technologies available, finding the most suitable systems for specific needs can significantly impact overall efficiency. This article presents a curated list of the ten best Assembly Conveyor Systems, aiming to guide manufacturers in making informed choices that align with their operational goals. By understanding the features and benefits of these systems, organizations can better equip themselves to thrive in today’s competitive market.

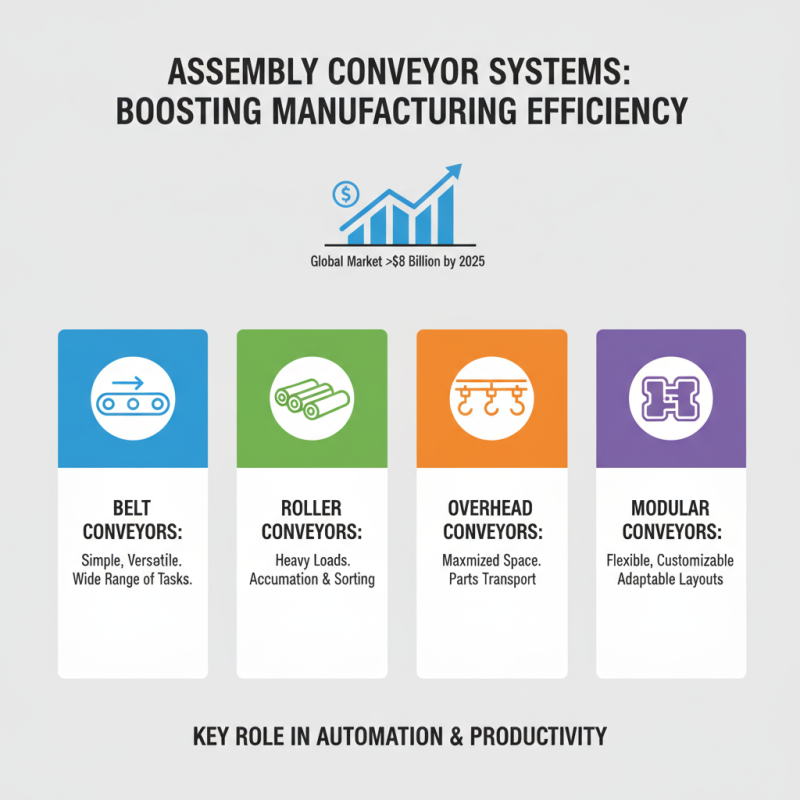

Assembly conveyor systems play a crucial role in enhancing productivity and efficiency in manufacturing environments. These systems come in various types, each tailored to meet specific operational needs. The most common types include belt conveyors, roller conveyors, overhead conveyors, and modular conveyor systems. Belt conveyors, for instance, are often favored for their simplicity and versatility, making them suitable for a wide range of assembly tasks. According to industry reports, the global conveyor system market is expected to grow significantly, with a projected value of over $8 billion by 2025, reflecting the increasing demand for automation in production processes.

In addition to belt and roller systems, overhead conveyors provide unique advantages in settings where floor space is limited. They allow for the efficient transportation of materials while keeping the workspace clear. Modular conveyor systems, on the other hand, offer the flexibility to expand and adapt to changing production needs, making them a popular choice among manufacturers seeking to scale operations without major disruptions.

Tips: When selecting an assembly conveyor system, consider factors such as the type of products being transported, the production rate, and the layout of your facility. Collaborating with industry experts can also provide insights into optimizing your assembly line for maximum efficiency. Implementing regular maintenance schedules can prevent downtime and ensure the longevity of your conveyor systems, ultimately leading to more sustainable operations.

When selecting assembly conveyor systems for efficient production lines, there are several crucial features to consider. One key aspect is the load capacity of the conveyor. According to a report by MarketsandMarkets, the global conveyor systems market is projected to reach USD 7.8 billion by 2025, indicating a growing emphasis on robust systems that can handle various weights. Understanding the specific load requirements of your production line will help determine the most suitable conveyor type, whether it's a belt, roller, or modular system.

Another important feature is the flexibility and scalability of the conveyor system. As production demands fluctuate, having a system that can adapt is essential. Data from IBISWorld suggests that companies that invest in modular conveyor solutions witness a 10-15% increase in operational efficiency. Scalability allows businesses to expand their lines easily without significant downtime or additional capital investment. Integrating automation and smart technologies, such as real-time tracking and analytics, into the conveyor systems is also vital. These features not only enhance productivity but also facilitate better decision-making based on accurate data insights, ultimately leading to more efficient production processes.

In modern manufacturing, the efficiency of production lines can significantly impact overall productivity and profitability. A report from the National Association of Manufacturers (NAM) emphasizes that organizations that invest in advanced conveyor systems often experience a 20-30% increase in operational efficiency. This is largely due to reduced manual handling and faster assembly processes, allowing companies to meet growing market demands more effectively.

The choice of assembly conveyor systems is crucial, as different configurations can cater to varied production needs. Research indicates that belt conveyors, modular conveyors, and roller conveyors are among the most widely adopted systems, with modular designs offering flexibility and scalability to adapt to changing production volumes.

Furthermore, integrating automation into these systems can lead to a reduction in labor costs by up to 40%, according to the International Federation of Robotics' statistics. By embracing innovative assembly conveyor solutions, manufacturers can enhance their productivity while maintaining high standards of quality and safety in their operations.

In the rapidly evolving manufacturing landscape, selecting the right assembly conveyor system is crucial for optimizing production efficiency. A comparative analysis based on industry needs reveals that factors such as load capacity, speed, modularity, and ease of maintenance should be prioritized. According to a recent report by the International Material Handling Association (IMHA), nearly 70% of manufacturing companies regard conveyor systems as integral to their operational efficiency, emphasizing the need for tailored solutions to meet specific industry demands.

Different industries have unique requirements. For instance, automotive manufacturers often require high-speed conveyors that can handle heavy loads with precision, while electronics assembly lines may benefit from modular systems that allow for quick reconfiguration. A survey conducted by the Conveyor Equipment Manufacturers Association (CEMA) highlighted that industries embracing advanced automation and intelligent control systems reported a 30% increase in productivity. These statistics underscore the significance of aligning conveyor system selection with particular industry needs, ensuring that production lines operate smoothly and efficiently.

Tips: When evaluating conveyor systems, consider conducting a thorough needs assessment to determine your specific operational requirements. It's essential to involve stakeholders from various departments to gather insights on workflow and potential bottlenecks. Additionally, keep scalability in mind—selecting systems that can easily adapt to future technological advancements or changes in production processes will save time and resources down the line.

The future of assembly conveyor systems is being shaped by significant technological advancements and innovative practices that enhance efficiency in production lines. According to a report by Markets and Markets, the global conveyor system market is projected to reach USD 7.3 billion by 2025, growing at a CAGR of 4.5%. This growth is driven by the increasing demand for automation in manufacturing, with smart conveyor technology taking center stage. Automation not only streamlines operations but also reduces labor costs, which is one of the significant factors influencing manufacturer adoption rates.

Emerging trends in assembly conveyor systems include the integration of IoT (Internet of Things) capabilities, AI-driven analytics, and advanced materials. The use of IoT allows for real-time monitoring and data collection, providing actionable insights to optimize system performance. AI technologies enable predictive maintenance, which reduces downtime and enhances productivity. Additionally, the development of modular conveyor systems is gaining popularity, allowing manufacturers to easily adapt and scale their production lines based on market demands. With these innovations, assembly conveyor systems are poised to play a critical role in creating more efficient and flexible production environments tailored to meet the challenges of the rapidly evolving industrial landscape.

This chart illustrates the production efficiency percentages of ten assembly conveyor systems, reflecting their performance and the potential innovations driving future trends in the industry.