The tire industry faces increasing demands for efficient handling and storage solutions. The "Tire Conveyor And Storage Line" plays a crucial role in meeting these challenges. These systems optimize the storage and transportation of tires, reducing time and labor costs.

In 2026, advancements in technology and design will reshape how these conveyors function. Companies will need to adapt their practices to stay competitive. It’s important to consider the layout and automation options that enhance operational flow. Picking the right components is vital, yet many overlook this aspect. Errors in selecting equipment can lead to delays and increased expenses.

Addressing these challenges requires a focus on quality and innovation. Businesses should also reflect on how the current systems impact productivity and safety. The balance between efficiency and cost-effectiveness must be continuously assessed. Embracing change in the "Tire Conveyor And Storage Line" can lead to significant improvements. However, companies must remain vigilant about pitfalls in implementation and management. Each choice shapes future success in this evolving landscape.

Tire conveyor systems play a vital role in the tire manufacturing and distribution process. They enhance efficiency, streamline operations, and reduce manual labor. A recent industry report highlights that tire conveyors can improve productivity by up to 30%. This increase stems from the ability to handle large volumes of tires with minimal human intervention.

Understanding the importance of these systems is crucial. They can significantly lower the risk of workplace injuries related to heavy lifting. In fact, approximately 25% of workplace injuries arise from material handling. Additionally, tire storage solutions integrated with conveyor systems can optimize space usage. Reports suggest that efficient storage may lead to a 15% reduction in storage costs.

However, these systems are not without challenges. Maintenance can be costly and time-consuming. Regular inspections are necessary to ensure operational efficiency. Many companies fail to prioritize this aspect, leading to unexpected downtimes. Investing in training workers on proper usage is essential but often overlooked. Thus, the importance of tire conveyor systems goes beyond just enhancing productivity; it encompasses safety and long-term operational viability.

| Tire Conveyor System Type | Load Capacity (lbs) | Belt Width (in) | Length Options (ft) | Typical Applications |

|---|---|---|---|---|

| Fixed Incline Conveyor | 2000 | 24 | 10 - 50 | Tire manufacturing and assembly |

| Modular Roller Conveyor | 1500 | 30 | 5 - 40 | Storage and transportation |

| Heavy-Duty Belt Conveyor | 4000 | 36 | 20 - 100 | Bulk tire transport and handling |

| Tire Storage System | Varied | N/A | Customizable | Long-term tire storage solutions |

Tire storage solutions play a crucial role in managing inventory efficiently. Effective systems utilize space optimally. A well-designed storage line allows for easy access to tires. This is essential in fast-paced environments. Proper organization helps reduce clutter and minimizes the risk of accidents. Without good organization, the operation can quickly become chaotic.

One must consider the material and structure of storage units. Choosing durable, weather-resistant materials is vital. They protect tires from degradation. Additionally, adjustable shelving can accommodate different tire sizes. This flexibility allows businesses to adapt as inventory changes. However, neglecting maintenance of these systems can lead to inefficiency. Regular checks can prevent costly replacements.

Automation is another key feature. Automated systems enhance efficiency by streamlining operations. They reduce human error but require proper training. Some workers may struggle with new technologies. This resistance can slow progress. Balancing automation with human oversight may be necessary for optimal performance. Investing in good training can bridge that gap.

This chart displays the effectiveness of various tire storage solutions based on key features such as Space Efficiency, Loading Speed, and Automation Level. The data represents the average performance ratings of different tire storage systems evaluated in 2026.

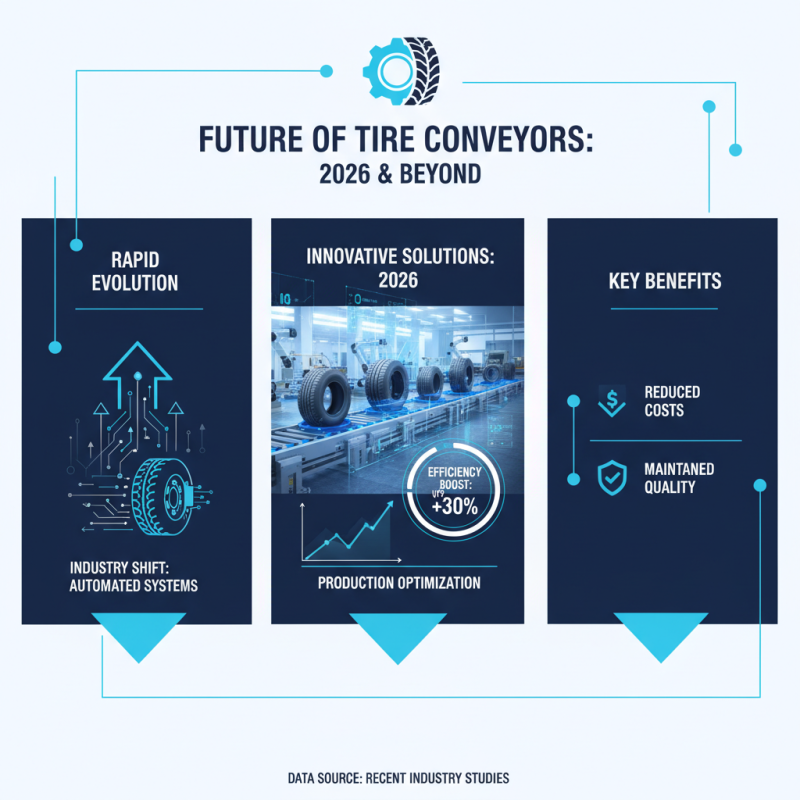

The tire industry is evolving rapidly, and so is the technology behind tire conveyors. By 2026, innovative solutions will transform how tires are handled in manufacturing and storage. Recent studies suggest that automated systems can increase efficiency in tire production facilities by up to 30%. This shift is crucial, as the industry faces pressures to reduce costs while maintaining high quality.

One key area of innovation is the integration of smart sensors. These sensors track items in real-time, ensuring better inventory management. They can detect tire quality and size variations during transport. Moreover, cutting-edge conveyor designs have minimized space usage in warehouses by 25%. This optimization is vital for companies with limited floor space.

However, not all innovations are flawless. Some companies struggle with the high initial costs of these technologies. Up to 40% of expenditures may go toward upgrading outdated systems. Additionally, staff training remains a challenge. Workers must adapt to new technologies, which can create temporary slowdowns. Each of these issues highlights the need for ongoing reflection and improvement in the adoption of tire conveyor solutions.

When exploring tire conveyor systems, various options are available. Every system serves a unique purpose. Some excel in speed, while others focus on capacity. Understanding these differences is crucial for making an informed choice.

Speed is vital in high-volume environments. However, faster systems may sacrifice other features like durability. A slower conveyor can sometimes offer better long-term benefits. It's essential to consider whether speed or reliability is the priority for your operation.

Storage solutions also play a significant role in efficiency. Some systems integrate storage features, helping you manage space effectively. Others may require additional equipment, leading to complexity. Evaluating your specific needs will help avoid potential pitfalls in your setup. Ensure that the chosen system aligns with your overall operational goals.

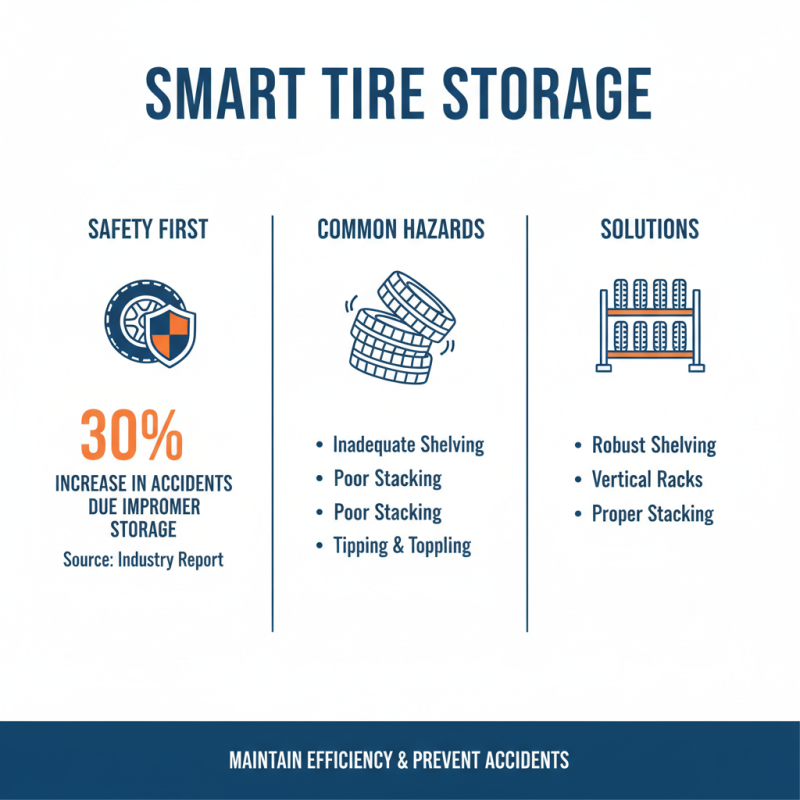

Tire storage solutions play a vital role in maintaining safety and efficiency. According to a recent industry report, improper tire storage can lead to a 30% increase in accidents. Inadequate shelving and stacking can cause tires to topple. This hazard is often overlooked but requires attention.

Regular maintenance is critical. Implementing a system for checking tire integrity can prevent issues. A study found that only 20% of companies perform routine inspections. This neglect can lead to costly damages and safety risks. Proper signage and access control can also reduce incidents in storage areas.

Training staff on best practices is essential. Many workers are unaware of proper lifting techniques. This oversight often results in injuries. Simple training sessions can make a significant difference. Moreover, tracking tire usage is often ignored, leading to overstock. Understanding stock levels can enhance organization, reducing clutter. Effective tire storage relies on consistent efforts and awareness of dangers.