In today's fast-paced industrial landscape, the adoption of Intelligent Conveyor Systems has become a pivotal element for businesses aiming to enhance operational efficiency and adaptability. According to a recent report by MarketsandMarkets, the global smart conveyor system market is projected to grow from USD 4.86 billion in 2020 to USD 7.88 billion by 2025, showcasing a compound annual growth rate (CAGR) of 10.1%. This rapid expansion highlights the increasing demand for automated solutions that streamline material handling processes, reduce labor costs, and improve overall productivity.

As companies seek to gain a competitive edge, understanding how to select the right Intelligent Conveyor System tailored to their specific needs is crucial. This ultimate guide will provide insights into key considerations, enabling you to make informed decisions that align with your business objectives and operational requirements.

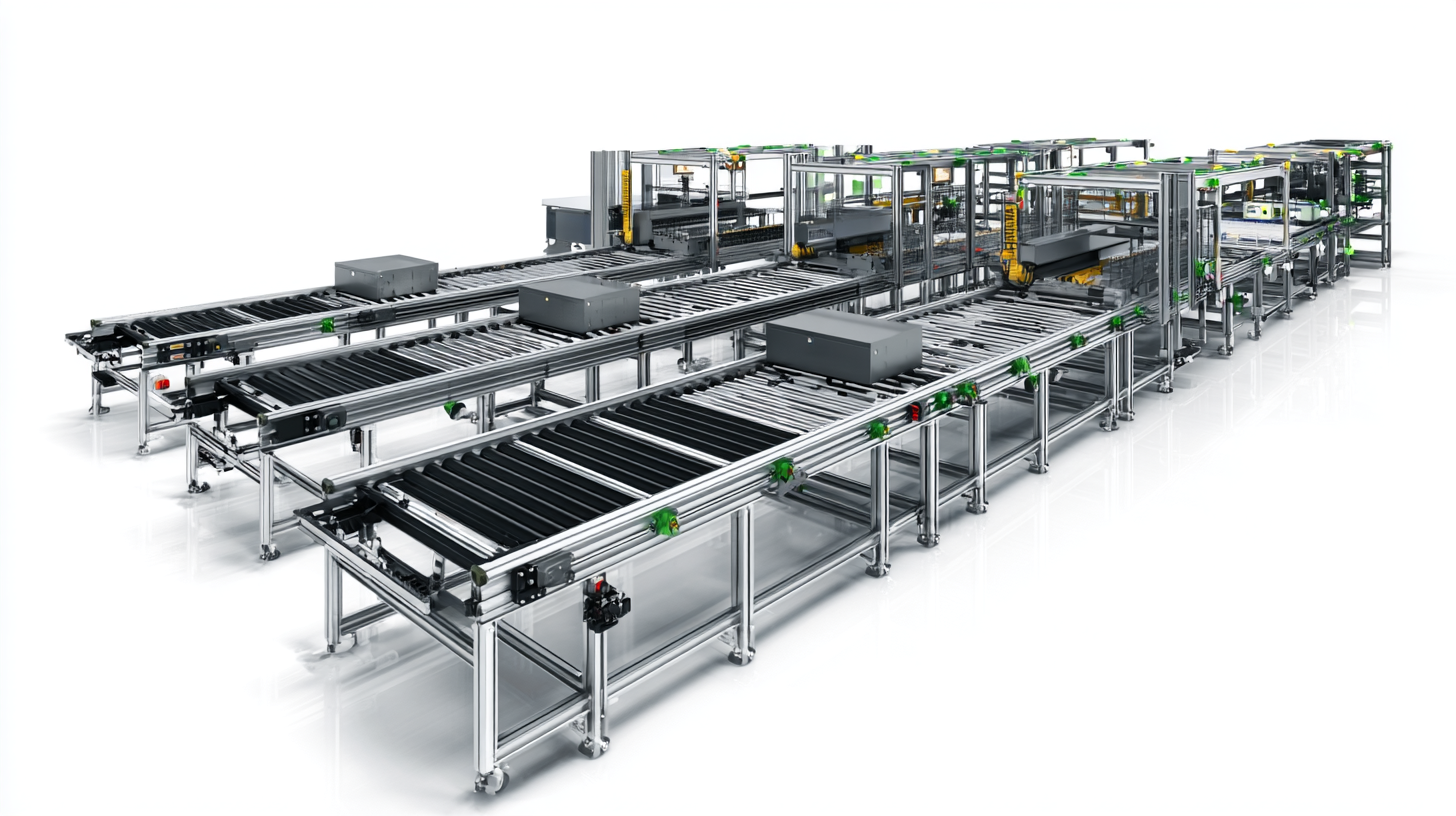

Understanding intelligent conveyor systems is crucial for any business looking to optimize operations and enhance productivity. These advanced systems integrate cutting-edge technology to streamline material handling processes, ensuring a seamless flow of goods. Key features often include advanced sensors, automated controls, and real-time data analytics, which allow for greater visibility and efficiency in logistics operations. By implementing intelligent conveyor systems, businesses can achieve faster processing times and reduce manual labor, ultimately lowering operational costs.

The benefits of intelligent conveyor systems extend beyond efficiency and cost savings. They also provide scalability, enabling businesses to adapt to changing demands without significant overhauls of existing infrastructure. Moreover, integrating these systems can enhance workplace safety by minimizing manual handling and reducing the risk of accidents. With continuous monitoring and predictive maintenance features, intelligent conveyor systems can identify potential issues before they become problems, further contributing to a reliable and efficient operation. Overall, understanding these key features and benefits can guide businesses in making informed decisions about their logistics and material handling strategies.

In recent years, the industrial landscape has undergone significant transformation, particularly with the advancement of automation technologies in conveyor systems. According to a report by the International Federation of Robotics, the global market for industrial robots, integral to automating conveyor systems, is expected to grow by 12% annually, reaching over $70 billion by 2025. This surge reflects the increasing demand for efficiency and precision in manufacturing processes, paving the way for companies to integrate more intelligent conveyor systems that can adapt to varying production requirements.

Automation's impact on conveyor systems extends beyond just speed and efficiency; it also enhances data collection and analysis capabilities. A study from the Logistics Management Insights found that companies implementing automated conveyor solutions have seen a 30% reduction in operational costs and a 25% increase in output. These intelligent systems can adjust automatically to fluctuations in workflow, integrate seamlessly with other automated processes, and provide real-time analytics, transforming how businesses manage their supply chains. As automation continues to permeate the industry, the strategic choice of conveyor systems becomes critical for maintaining a competitive edge.

When considering the implementation of intelligent conveyor systems, a comprehensive cost-benefit analysis is essential to evaluate the return on investment (ROI). Industry reports indicate that businesses can achieve a remarkable 30% increase in operational efficiency by integrating these advanced systems. Furthermore, a recent study published by the Material Handling Industry (MHI) highlighted that companies using intelligent conveyor solutions can reduce labor costs by approximately 20%, allowing them to reallocate resources towards more strategic initiatives.

Tip: Before making a purchase, calculate your current operational costs versus projected savings. This strategy will provide clarity on potential ROI and help in making an informed decision.

Moreover, intelligent conveyor systems often come equipped with data analytics capabilities that allow for real-time monitoring of product flow. According to the International Society of Automation, implementing such technologies can lead to up to a 50% reduction in downtime, significantly impacting overall productivity metrics.

Tip: Invest time in understanding the specific needs of your operations. Consider conducting a pilot program to evaluate the effectiveness of the conveyor system in your unique business environment before full-scale implementation.

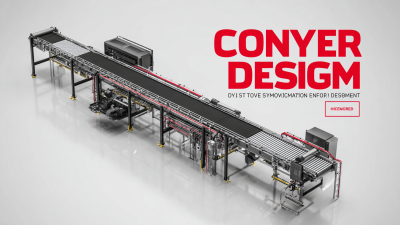

When selecting intelligent conveyor systems, understanding the various types of technologies available is crucial for optimizing your operations. According to a recent report by Research and Markets, the global conveyor systems market is projected to reach $9.2 billion by 2025, driven by the increasing demand for automation in manufacturing and logistics. The three primary types of intelligent conveyors include belt conveyors, roller conveyors, and modular conveyor systems, each offering unique advantages suited for different applications.

Belt conveyors are versatile and widely used in various industries for their ability to transport large volumes of goods smoothly. Meanwhile, roller conveyors excel in applications requiring heavy loads, providing efficient transfer between different levels of production. Modular conveyor systems offer extraordinary flexibility, allowing businesses to reconfigure layouts easily as their operational needs evolve. A study by Allied Market Research indicates that modular automation is gaining traction, expected to show a compound annual growth rate (CAGR) of over 10% from 2020 to 2027, signaling a shift towards more adaptable solutions in material handling. By carefully comparing these technologies, businesses can select the right system that aligns with their specific operational goals and growth plans.

| Conveyor Type | Key Features | Industry Applications | Cost Estimate ($) |

|---|---|---|---|

| Automated Conveyor System | Sensors, AI Integration, Real-time Monitoring | Manufacturing, Warehousing | $15,000 - $50,000 |

| Belt Conveyor | Simple Design, Low Maintenance, High Load Capacity | Food and Beverage, Packaging | $5,000 - $20,000 |

| Modular Conveyor System | Flexible Configuration, Easy Maintenance | E-commerce, Automotive | $10,000 - $30,000 |

| Overhead Conveyor | Space-Saving, High Throughput | Textile, Automotive | $20,000 - $60,000 |

| Roller Conveyor | Durable, Low Friction, Heavy Load Handling | Warehouse, Distribution Centers | $7,000 - $25,000 |

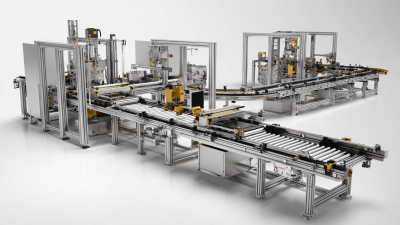

In today's rapidly evolving business landscape, integrating AI and IoT into conveyor systems is essential for future-proofing operations. The demands for efficiency in the global supply chain have surged, with logistics real estate usage increasing by 57% over the past decade. Embracing intelligent conveyor systems equipped with cutting-edge technologies can significantly enhance productivity and streamline processes.

Innovations such as advanced palletizers and robotic systems not only boost line efficiency but also adapt to changing consumer demands. Companies are increasingly adopting solutions that leverage AI to optimize workflows and decision-making, allowing for a more resilient supply chain. As we move forward, investing in these intelligent conveyor systems will be critical for businesses aiming to maintain a competitive edge and respond to the dynamic challenges of global trade.