Choosing the right Assembly Conveyor Systems for your business is crucial. These systems streamline operations and boost productivity. However, the selection process can be overwhelming.

Consider different factors. Your production volume and product types play significant roles. An assembly line for large items requires a robust system. Compact systems work better for smaller, lighter products. Complexity can arise in decision-making, leading to errors in judgment.

Evaluating your needs before purchasing is essential. Engage with suppliers to understand options. Sometimes, simpler systems are more effective. Ensure that the system you choose actually fits your workflow. Reflecting on past experiences can guide you. A well-chosen assembly conveyor can transform operations dramatically.

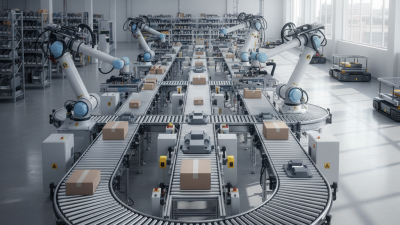

Understanding the role of assembly conveyor systems in manufacturing is crucial. These systems enhance productivity, reduce manual labor, and streamline operations. According to a recent industry report by the International Society of Automation, assembly lines equipped with effective conveyor systems can boost efficiency by up to 30%. This figure highlights how critical these systems are for modern manufacturing.

However, not all assembly conveyor systems are created equal. Choosing the right one can be challenging. Factors such as load capacity, flexibility, and installation cost must be considered. A poorly designed system can lead to bottlenecks, causing delays in production. Many companies underestimate the importance of proper alignment and integration within their current workflows. Mismanagement in choosing the right system can result in significant operational setbacks.

Additionally, the maintenance of these systems is often overlooked. Regular checks are essential to prevent breakdowns. A survey from the Manufacturing Institute indicated that 28% of companies experience unplanned downtime due to conveyor failures. This statistic serves as a reminder to invest in regular maintenance. Neglecting this aspect could lead to increased repair costs and production losses, reinforcing the need for diligence in system selection and upkeep.

| Feature | Description | Considerations | Cost Estimate ($) |

|---|---|---|---|

| Conveyor Type | Different types include belt, roller, chain, and modular. | Choose based on the type of products being handled. | $1,000 - $5,000 |

| Load Capacity | Maximum weight the conveyor system can handle at a time. | Consider the heaviest items you plan to transport. | $500 - $3,000 |

| Speed | The speed at which products are moved along the conveyor. | Match speed to production requirements. | $300 - $2,000 |

| Modularity | Ability to adjust and extend the conveyor system as needed. | Useful for growing businesses or changing processes. | $800 - $4,000 |

| Automation Level | Extent of automated controls and integration with machinery. | Higher automation usually means higher cost. | $2,000 - $10,000 |

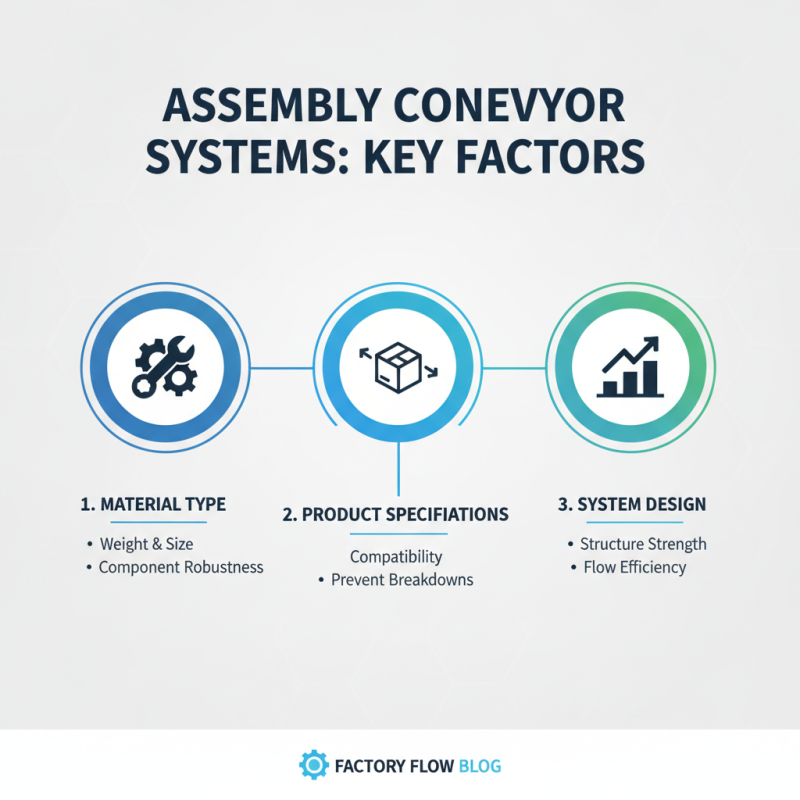

Choosing the right assembly conveyor systems requires careful consideration of several key factors. One primary aspect is the type of materials being processed. Different systems are designed to handle various weights and sizes. For instance, systems that convey heavy components often demand more robust structures. It’s essential to assess your product specifications to ensure compatibility, as mismatches can lead to frequent breakdowns.

Another important factor is the layout of your workspace. According to the Conveyor Equipment Manufacturers Association, about 70% of conveyor system failures arise due to poor design. Space constraints can restrict the type of conveyor you select, so understanding the physical configuration of your facility is critical. Moreover, a well-planned system can improve efficiency, with studies showing that optimized conveyor layouts boost productivity by up to 25%.

Additionally, consider the future of your operations. A flexible conveyor system can adapt to changing production demands. Research indicates that companies that choose adaptable systems often see a return on investment in less than two years. However, it’s vital to avoid overestimating your needs; selecting a system that’s too advanced can lead to unnecessary costs. Reflect on your current and future requirements before making a decision.

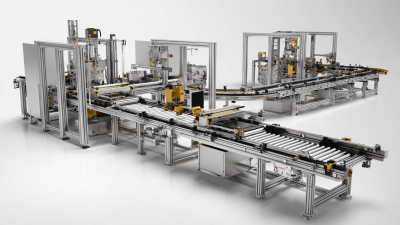

Choosing the right assembly conveyor system relies heavily on understanding its types and applications. There are several specific systems designed to meet various operational needs. For instance, belt conveyors are widely used for their versatility. They can efficiently move items of different shapes and sizes. However, they might not be ideal in environments where high-speed operations are crucial.

Roller conveyors serve another purpose. They are perfect for sorting and transporting heavy products. These systems can be manually controlled or automated. But, their complexity can lead to maintenance challenges, especially in high-use situations. Modular conveyors are also gaining popularity. They provide customization options for unique layouts. Yet, it may require extra planning to optimize their use effectively.

Overall, assessing the material handling requirements is vital. Different systems can impact production efficiency. It’s important to consider your specific needs and potential limitations. A system that works well for one operation may fall short in another. Therefore, a careful evaluation of options will guide the right choice.

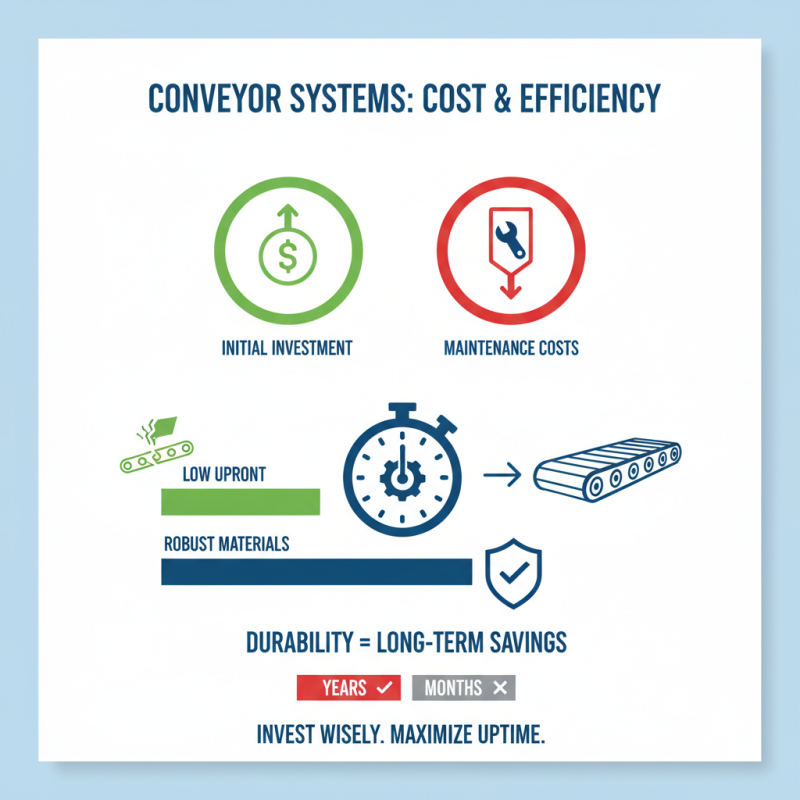

When evaluating conveyor system options, cost and efficiency take center stage. It's essential to consider the initial investment. Some systems may seem affordable but can incur high maintenance costs over time. Look into the durability of materials used. Investing in robust equipment can save you money in repairs. A conveyor system should last years, not months.

Efficiency must also be measured. A well-designed system can streamline your workflow considerably. Evaluate speed and load capacity against your production needs. If your system underperforms, it impacts output. Get feedback from your team on bottlenecks. Their insights may reveal what isn't working in real-time. This can help you rethink your choice.

Maintenance costs are often overlooked. Regular upkeep can prevent larger breakdowns. Ensure that your selected system allows for easy access to parts. You might want to reflect on the training provided for your staff. A poorly trained team can negate the system's advantages. Balancing cost, efficiency, and usability is crucial for long-term success.

Maintaining assembly conveyor systems is crucial for long-term efficiency. Regular maintenance can prevent costly downtimes. A report by the Association for Manufacturing Technology indicates that unplanned downtime can lead to losses of up to $260,000 per hour. This underscores the need for a solid maintenance plan.

Proper support services also play a vital role. Companies must ensure access to technical support. Studies show that 75% of conveyor system failures are due to improper maintenance. Users should consider training for staff. Knowledgeable personnel can make a big difference. Having a dedicated maintenance team can enhance system longevity.

Failing to prioritize maintenance often leads to issues. Overlooking small repairs can escalate into major problems. It’s important to schedule regular inspections. Maintenance logs are essential for tracking performance. Simple actions today can save significant costs tomorrow. Embracing a proactive approach yields long-lasting benefits.