Choosing the right Automation Conveyors can be challenging. Many factors must be considered. Different industries have unique needs. What works for one business may not suit another.

Automation Conveyors streamline production lines. They enhance efficiency and reduce human error. For example, a manufacturing plant may need heavy-duty conveyors. In contrast, a food processing facility might require sanitary options.

Despite these differences, some businesses overlook important details. They may focus solely on cost, ignoring quality. This can lead to problems later. Careful consideration is essential for optimal performance. Each choice impacts workflow and productivity. Making informed decisions will benefit your business in the long run.

When selecting automation conveyors, it’s crucial to understand the various types available in the market. The global conveyor system market is projected to grow by 4.6% annually. This growth reflects the increasing demand for more efficient logistics systems. Each type of conveyor serves specific needs and understanding these can greatly influence operational efficiency.

Belt conveyors are commonly used due to their versatility. They can handle a wide range of products, from fragile items to heavy packages. However, they may require constant maintenance. Roller conveyors are another popular option, particularly in warehouses. They facilitate easy movement of goods but depend heavily on gravity and need manual intervention for loading and unloading.

In contrast, modular conveyors offer flexibility and can be adjusted to fit various layouts. According to a recent industry report, 30% of companies overlooked conveyor compatibility with existing systems, leading to costly adjustments. It’s essential to evaluate your specific requirements and consider factors like load capacity and available space. Failing to do so might result in inefficiencies that could reflect poorly on overall performance.

Choosing the right automation conveyors for your business involves understanding critical factors influencing selection. First, consider the type of materials being transported. A report by the Conveyor Equipment Manufacturers Association (CEMA) notes that different conveyor types handle specific weights and sizes. For instance, heavy-duty conveyors are designed for bulky items, while modular systems can adapt to diverse product ranges.

Another factor is the layout of your facility. The National Institute of Standards and Technology (NIST) suggests optimizing space utilization is essential for efficiency. Bend radius, height, and available space can restrict conveyor options. Assessing your current workflow can reveal if modifications are needed.

Tips: Evaluate your current and future needs. Select versatile conveyors that can grow with your business. Also, don’t overlook maintenance; regular checks can prevent costly downtimes.

Additionally, the integration of automation systems must be considered. A surveyed 72% of manufacturers reported improved efficiency with automated systems. However, these systems require thoughtful implementation. Training staff on new technology can pose challenges.

Ultimately, careful evaluation of these key factors will facilitate a more informed decision. The consequences of oversights can impact productivity and profitability. Make sure to reflect on each choice thoroughly.

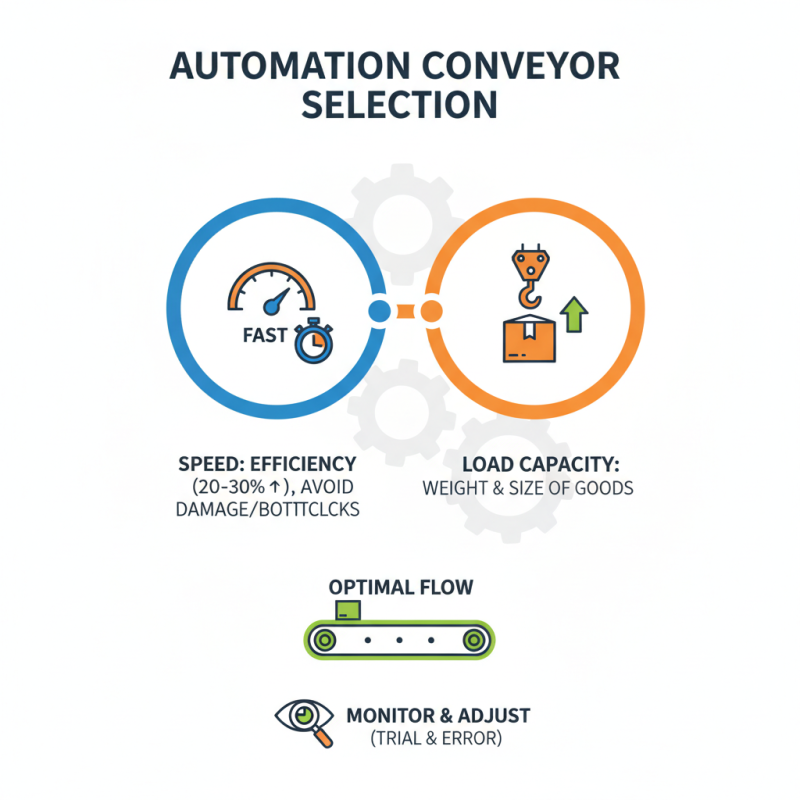

When choosing automation conveyors, speed and load capacity are crucial factors. Conveyor speed determines how quickly goods move along the line. According to industry reports, optimal conveyor speed can improve efficiency by 20-30%. Too fast may cause product damage, while too slow can lead to bottlenecks. Finding the right speed often requires trial and error. It’s important to monitor the entire process.

Load capacity is another vital aspect. Conveyors need to handle various weights and sizes. Studies show that exceeding load capacity can lead to breakdowns. It can also slow down operations significantly. Ensure your chosen conveyor can handle peak loads without strain. It might be wise to overestimate capacity needs to account for future growth.

Monitoring performance after installation helps refine these choices. Be open to adjustments. Data analytics can provide insights into speed and load issues. This step is essential for optimizing operations over time. As pressures increase in supply chains, understanding these elements can set businesses apart.

When considering automation conveyor solutions, evaluating the Return on Investment (ROI) is crucial. Many businesses overlook this step. They might rush into purchasing systems that don’t align with their goals. A thorough assessment helps avoid costly mistakes.

Calculating ROI requires examining multiple factors. Start with current labor costs. How much time do your employees spend on manual processes? Next, look at system efficiency. Will the conveyor reduce errors? These details matter. They can reveal potential savings over time. Additionally, don’t forget maintenance costs. Can your team handle repairs? If not, outsourcing may increase long-term expenses.

Observe your operations closely. Are there bottlenecks? Do delays occur frequently? These inefficiencies can quickly drain resources. Automation may offer solutions, but only if properly matched to your needs. Sometimes, the initial investment can feel daunting. Yet, a well-implemented system could pay dividends in efficiency and savings. Reflect on your unique operational challenges to make informed decisions about conveyor automation.

When selecting automation conveyors, industry-specific needs play a crucial role. Different sectors have unique requirements that can affect conveyor performance. For example, food and beverage industries require hygienic designs. These conveyors must withstand heavy cleaning without degrading. A robust stainless steel frame often works best here. Likewise, in manufacturing, durability is key. Conveyors should handle heavy loads and constant operation.

Customization is critical. Manufacturers often provide tailored solutions. This can mean adjusting the conveyor's width, speed, or materials used. A common issue is overlooking these specific needs, leading to inefficiencies. What works in one sector may fail in another. For example, pharmaceutical conveyor systems need to meet strict regulations. This ensures compliance, safety, and product integrity.

Consider automation methods as well. Simple belt loaders may suffice for some operations. Others might need complex sorting capabilities. Reflecting on operational needs is vital. Successful integration of conveyor systems relies on understanding these nuances. Engaging with various teams in the business can help identify essential features. Everyone should have a voice in the selection process. This will promote better outcomes and operational success.