Choosing the right automation conveyor systems for your business is a crucial step in enhancing operational efficiency and productivity. As industries increasingly move towards automation, conveyor systems have become a staple in manufacturing and logistics. These systems streamline workflows, reduce manual labor, and minimize errors, making them an essential investment for businesses seeking to stay competitive. However, with the plethora of options available in the market, selecting the right system can be daunting.

When evaluating automation conveyor systems, it is vital to consider the specific needs and goals of your business. Factors such as the type of products being handled, production volume, and available space can significantly influence the choice of a conveyor system. Additionally, understanding the integration capabilities with existing equipment and the overall scalability for future expansions can help in making an informed decision. This introduction sets the stage for a comprehensive exploration of the key considerations and strategies for selecting automation conveyor systems tailored to your unique operational requirements.

Identifying your business requirements for conveyor systems is a crucial first step in selecting the right automation conveyor system. To begin, assess the types of materials you will be handling. Consider their size, weight, and form—this will influence the conveyor design, such as whether you need a belt conveyor, roller conveyor, or specialized systems like screw conveyors. Understanding the characteristics of the materials, including their fragility or abrasiveness, will help ensure that the chosen system can efficiently and safely transport them without damage.

Next, evaluate the layout of your facility and the volume of products you need to move. A thorough understanding of your operational workflow will allow you to identify the ideal conveyor system that fits within your current space and workflow patterns. For instance, if your operations require frequent changes in direction, a flexible conveyor system may be necessary. Additionally, analyze the speed and efficiency requirements; knowing how quickly products need to be transported can guide you in selecting a system with appropriate motor and drive components to meet your productivity goals.

| Business Requirement | Recommended Conveyor System Type | Key Features | Estimated Cost |

|---|---|---|---|

| High Volume Production | Roller Bed Conveyor | Durable, High-speed, Low-friction | $10,000 - $25,000 |

| Fragile Items Handling | Belt Conveyor | Gentle Handling, Flexible Routing | $7,000 - $15,000 |

| Heavy Load Transport | Chain Conveyor | High Load Capacity, Rugged Design | $15,000 - $30,000 |

| Automated Sorting Solutions | Cross-belt Sorter | Fast Sorting, High Accuracy | $50,000 - $120,000 |

| Space Efficiency | Incline/Decline Conveyor | Space-saving, Multi-directional | $5,000 - $10,000 |

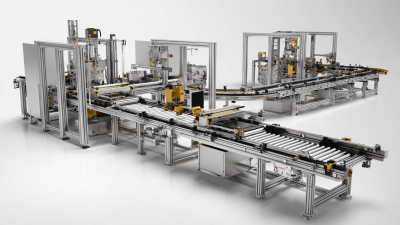

When considering automation conveyor systems for your business, understanding the different types available is crucial. These systems can be categorized mainly into several types, including belt conveyors, roller conveyors, and modular conveyors. Belt conveyors are widely used for their versatility and ability to transport goods in various industries, including manufacturing and packaging. According to a report by Research and Markets, the global conveyor systems market is projected to reach $12 billion by 2026, reflecting a growing reliance on automation for efficiency and productivity.

Roller conveyors offer an effective solution for transporting heavier items. They utilize a series of rollers to facilitate the movement of loads, making them ideal for warehouses and distribution centers. As highlighted in a recent industry analysis by Technavio, automation in logistics has heightened the demand for roller conveyors, with an anticipated compound annual growth rate (CAGR) of over 5% from 2021 to 2025. Furthermore, modular conveyors provide adaptability and are designed for various configurations, allowing for easy customization to meet specific operational needs.

Selecting the right type of conveyor system also hinges on understanding the specifics of your operational requirements, such as load size, weight, and the nature of the product being moved. With the evolution of technology, features like smart sensors and IoT integration are becoming standard in modern conveyor systems, enhancing monitoring and efficiency. As such, making an informed decision by evaluating these options can significantly impact your business's workflow and operational success.

When selecting the ideal automation conveyor system, a primary consideration is the available space and layout of your facility. According to a report by the Material Handling Industry of America (MHIA), improper space planning can lead to inefficiencies costing companies up to 30% in operational expenses. To prevent this, it’s essential to thoroughly evaluate the dimensions and configuration of your workspace. Factors such as overhead clearance, aisle width, and entry/exit points must be assessed to ensure a smooth integration of the conveyor system without impeding current workflows.

Additionally, considering the flow of materials and products through your facility is crucial. Studies highlight that optimizing conveyor layout not only enhances productivity but also improves safety. A well-organized layout reduces congestion and minimizes the risk of accidents, which, according to the Occupational Safety and Health Administration (OSHA), can lead to thousands of dollars in penalties and lost workdays. Businesses should aim to utilize strategies such as modular conveyor systems that adapt easily to changing operational needs, allowing for future expansions or reconfigurations without excessive downtime or costs. Ultimately, aligning the conveyor design with the intricacies of your operational space will create a more efficient and safer work environment.

When selecting automation conveyor systems, assessing compatibility with your existing operations is crucial to ensure seamless integration and optimal performance. According to a recent report by the Material Handling Industry of America, over 70% of companies that invest in automated conveyor systems cite compatibility issues as a significant setback, leading to unplanned downtime and increased costs. Therefore, understanding your current system's specifications, including dimensions, weight capacities, and control protocols, is the first step in making an informed decision.

Tips: Conduct a thorough assessment of your facility's layout to identify any potential limitations or requirements. Engaging with systems engineers or a specialized consultant can help highlight any compatibility gaps that might exist. Additionally, consider conducting a pilot test with a small-scale implementation to glean insights into how the new system interacts with your existing processes before committing to a full-scale rollout.

Furthermore, don’t overlook the importance of employee training when introducing new automation systems. A well-informed workforce can bridge compatibility gaps that may arise from process changes. Reports indicate that companies that prioritize training when implementing new technologies experience a 30% increase in operational efficiency. Therefore, fostering an environment of continuous learning and adaptation is necessary for ensuring that all components of your operation work harmoniously together.

When considering an automation conveyor system, calculating the budget and potential return on investment (ROI) is crucial for justifying the expenditure. A recent industry report indicated that companies adopting automated conveyor systems reported productivity increases by up to 30%, significantly enhancing throughput without a proportional increase in labor costs. This data suggests that the initial investment in conveyor systems can be offset by the improved operational efficiency and reduction in labor hours, leading businesses to recover their costs much faster than anticipated.

Furthermore, it's important to account for maintenance and training costs in the overall budget. According to the Conveyor Equipment Manufacturers Association, effective upkeep can extend the lifespan of conveyor systems by up to 50%. Therefore, investing in a well-planned maintenance strategy can deliver a higher ROI.

By aligning the choice of automation conveyor systems with specific operational needs and analyzing the long-term savings yielded from reduced downtime and improved efficiency, companies can make informed decisions that support both immediate and future financial goals.