In today's highly competitive business landscape, companies are increasingly turning to Conveyor and Automation systems to enhance operational efficiency and productivity. According to a report by the International Federation of Robotics, the implementation of automation technologies, including conveyor systems, has the potential to boost productivity by up to 30% in manufacturing sectors. This significant improvement can lead to reduced operational costs and heightened output, allowing businesses to stay ahead in a rapidly evolving market.

Moreover, a study published by the Association for Advancing Automation indicates that automation not only streamlines production processes but also improves workplace safety. By minimizing the need for manual handling of goods, companies can decrease the likelihood of workplace injuries, thus fostering a more secure working environment. Furthermore, integrating Conveyor and Automation systems facilitates a smoother logistics flow, enabling businesses to effectively respond to changing consumer demands and trends.

As we explore the myriad benefits of Conveyor and Automation systems, it becomes evident that these technologies are not merely a luxury but a necessity for businesses striving for efficiency and growth in today’s fast-paced economy. Investing in such systems can provide companies with a competitive edge, ensuring sustainability and long-term success.

In today's fast-paced industrial environments, the integration of

conveyor systems is essential for

enhancing operational efficiency. According to a report by the International Conveyor Association,

industries that employ conveyor systems can improve their productivity by up to 30%,

drastically reducing the time required for material handling. This increased efficiency not only streamlines workflows

but also minimizes labor costs, allowing businesses to allocate resources more effectively.

Furthermore, conveyor systems contribute significantly to workplace safety.

The Occupational Safety and Health Administration (OSHA) emphasizes that

automated material handling can reduce manual lifting injuries by as much as 50%.

With safety as a paramount concern in industrial settings, implementing conveyors helps mitigate risks and fosters a

healthier work environment. Additionally, the adaptability of conveyor systems means they can be tailored to specific

operational needs, enhancing flexibility in handling various materials and products, which is vital in

dynamic production landscapes.

By leveraging the benefits of conveyor and automation systems, industrial

operations can achieve higher levels of

efficiency, safety, and adaptability, making them a crucial investment for

businesses aiming to thrive in competitive markets.

Automation technologies have revolutionized the way businesses operate, significantly enhancing productivity and precision across various sectors. By integrating automated systems such as conveyor belts and robotic assemblies, companies can streamline their processes, reducing the time required for tasks while increasing output consistency. This transition not only minimizes human error but also allows for higher throughput rates, ensuring that production lines run smoothly and efficiently.

Furthermore, the implementation of automation technologies provides real-time data and insights, enabling businesses to monitor operations closely and make informed decisions. With advanced analytics, managers can identify bottlenecks, optimize workflows, and allocate resources more effectively, leading to reduced operational costs. In addition, automated systems can adapt to different production needs, offering flexibility that is vital in today’s fast-paced market. By fostering precision in processes and enhancing overall efficiency, automation technologies are essential tools for any business aiming to thrive in a competitive landscape.

Automating your business operations through conveyor and automation systems can lead to substantial cost savings and efficiency gains. A comprehensive cost-benefit analysis reveals that while the initial investment may seem significant, the long-term benefits often outweigh the costs. Automated solutions minimize human error, speed up production times, and reduce labor costs, leading to a quicker return on investment. Furthermore, enhanced operational efficiency can lead to increased product quality, which can attract more customers and boost revenues.

When considering implementing an automation system, it's essential to conduct a thorough analysis of your current operational costs. Identify areas where automation can reduce expenses, such as labor-intensive processes or tasks that are prone to errors. This understanding will help articulate the potential financial benefits accurately.

Tips: Consider starting with a pilot program that integrates automation into a particular segment of your operation. This approach allows you to measure the impact of automation without committing fully at first. Additionally, regularly evaluating the performance of the automation system post-implementation can provide insights for further optimization, ensuring that your business continues to reap the financial rewards of automated solutions.

Integrating conveyor systems with existing operations can significantly enhance overall business efficiency by streamlining workflows and reducing manual handling. Conveyor systems automate the transportation of goods, enabling faster movement from one process stage to another. This seamless integration allows businesses to optimize production lines by synchronizing various operations, minimizing downtime, and ensuring that each unit operates at peak capacity. As a result, employees can focus on more complex tasks that require critical thinking and problem-solving, rather than repetitive manual labor.

Moreover, the adaptability of conveyor systems means they can be customized to fit unique operational needs. Existing layouts can accommodate new conveyor solutions without significant disruptions. Whether it’s adjusting for changes in product size or incorporating additional features like sensors and automated controls, the flexible nature of these systems allows for efficient modifications. Consequently, businesses can respond swiftly to evolving market demands, ensuring that operations remain agile and competitive while effectively managing resources. This strategic integration not only leads to increased productivity but also supports a culture of continuous improvement within the organization.

| Feature | Benefit | Impact on Operations | Cost Efficiency |

|---|---|---|---|

| Flexible Design | Customizable to specific operation needs | Enhances workflow and reduces bottlenecks | Minimizes downtime and increases output |

| Increased Speed | Faster transport of materials | Improves overall production rate | Boosts revenue through higher efficiency |

| Automation Integration | Seamless connection with existing systems | Streamlines processes and reduces manual labor | Lowers labor costs and enhances productivity |

| Safety Features | Designed with employee safety in mind | Decreases risk of accidents and injuries | Reduces costs associated with workplace incidents |

| Reduced Energy Consumption | Energy-efficient designs | Lower operational costs and eco-friendly | Saves money on energy bills over time |

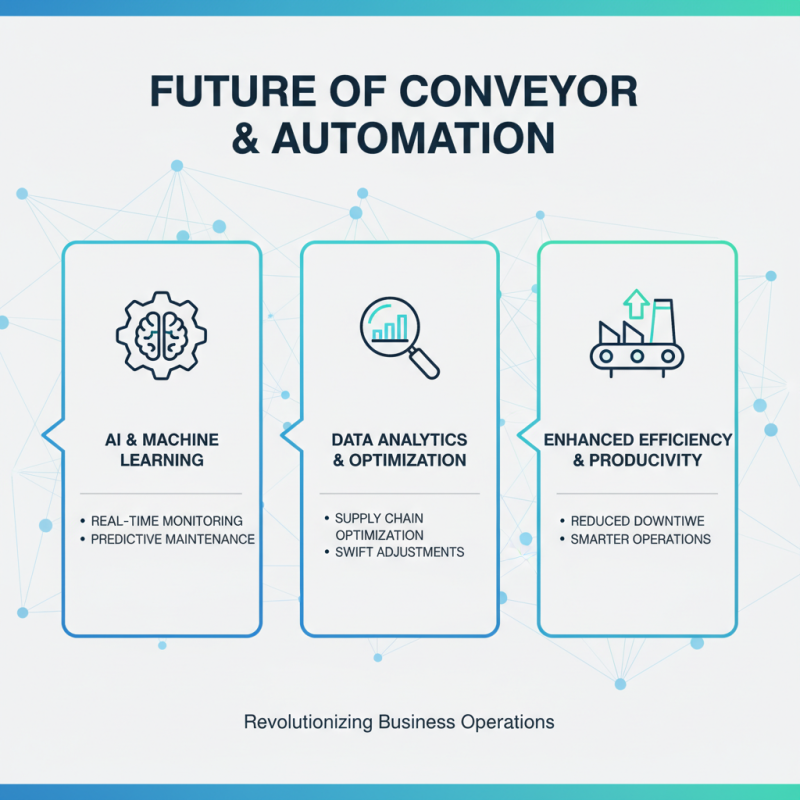

Future trends in conveyor and automation technology are poised to revolutionize the way businesses operate, enhancing efficiency and productivity. One of the most prominent trends is the integration of artificial intelligence and machine learning into conveyor systems. These technologies enable real-time monitoring and predictive maintenance, allowing businesses to anticipate failures before they happen and reduce downtime. By harnessing data analytics, companies can also optimize their supply chain processes, making adjustments swiftly based on actual performance metrics.

Another significant trend is the shift towards more flexible automation systems. Traditional fixed conveyor lines are increasingly being replaced by modular systems that can be easily reconfigured to accommodate changing product lines or production volumes. This adaptability not only maximizes space utilization but also supports rapid innovation in manufacturing processes. Additionally, the rise of autonomous mobile robots (AMRs) is transforming material handling, enabling seamless integration with conveyor systems to transport goods efficiently across vast facilities. As these technologies continue to evolve, businesses that embrace them will gain a competitive edge in the fast-paced market landscape.