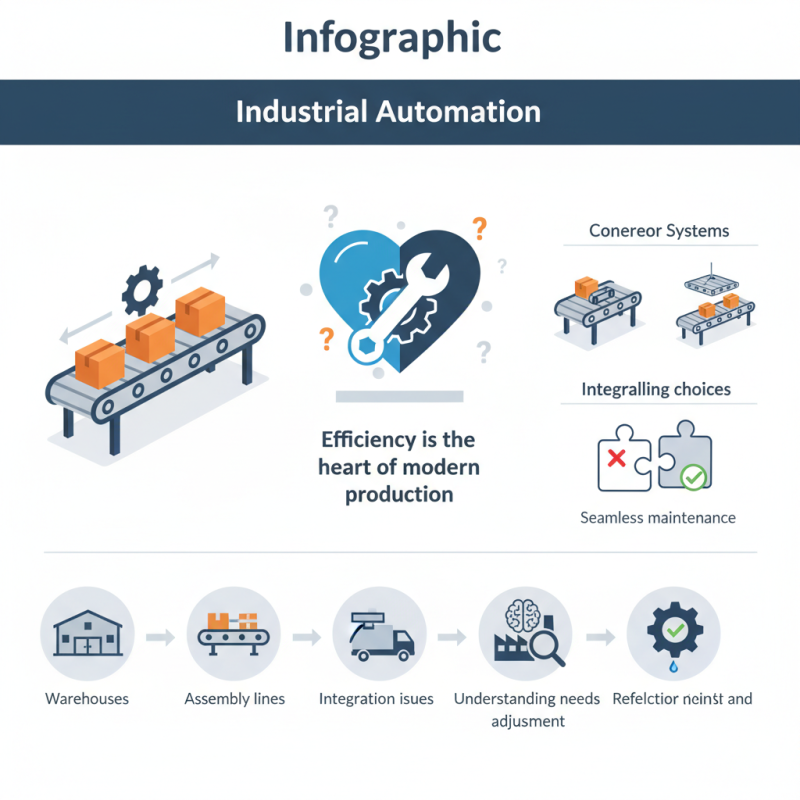

In the world of manufacturing, "Conveyor And Automation" play a crucial role. John Smith, an expert in automation technology, says, “Efficiency is the heart of modern production.” This statement highlights the importance of conveyors in enhancing productivity.

Conveyors transport materials with precision. They are vital in warehouses, assembly lines, and distribution centers. Automation technology improves their functionality. Various types of conveyors exist, each designed for specific tasks. Sometimes, the choices can be overwhelming.

Not all systems work seamlessly. Integration issues can arise, leading to inefficiencies. Regular maintenance is essential for optimal performance. Understanding the needs of your operation is crucial. This often requires reflection and adjustment.

A conveyor system is designed to move materials efficiently. It consists of a series of components working in harmony. These systems can transport anything from loose items to heavy machinery. Common types include belt, roller, and chain conveyors. Each type has its own specific application and advantages.

Tips: Always assess your material type before choosing a conveyor. Different materials may require unique systems for optimal efficiency.

Most conveyor systems are automated. This automation reduces manual labor and speeds up production. Sensors can track the materials' location, ensuring smooth operations. However, regular maintenance is crucial. Neglect can lead to breakdowns.

Tips: Schedule routine inspections to catch potential issues early. A small problem can lead to significant downtime.

In many industries, conveyors are essential. They improve logistics in warehouses and manufacturing plants. Choosing the right system can enhance productivity significantly. However, consider space limitations and system design carefully. A poor layout can hinder performance.

Conveyors play a vital role in various industries. They transport goods efficiently. Different conveyor types serve specific purposes. For instance, belt conveyors move bulk materials. They are commonly used in mining and agriculture. The continuous movement helps reduce manual labor.

Another type is the roller conveyor. This type utilizes rollers to facilitate movement. They work well for heavy packages. Warehouses often rely on them for sorting and distributing items. It’s common to see employees manually push boxes along these conveyors, which can sometimes slow down productivity.

In addition, there are spiral conveyors, ideal for vertical transport. They save space and can handle diverse products. However, they may require more maintenance. Choosing the right conveyor is crucial. The wrong fit can lead to inefficiency. Users must reflect on their specific needs.

Conveyor systems have transformed industries by enhancing efficiency. The automation aspect is critical here. Automation relies on controlling processes with minimal human intervention. This reduces errors and speeds up production.

Many conveyor systems use sensors and programmable logic controllers. These components work together to monitor and adjust the conveyor's operation. They can detect jams, measure weights, and even control speed. It's impressive how technology can streamline tasks. Yet, these systems also require regular maintenance. Overlooking this can lead to costly downtime.

Tips: Regularly inspect sensors. Ensure they are clean and functioning well. This helps avoid unexpected failures. Also, train staff to troubleshoot basic issues. Empowering your team can save time and money.

Understanding the principles of automation in conveyor systems is crucial. However, not every implementation is perfect. Some setups might need adjustments after they are operational. It’s vital to learn from these experiences. Embrace the trial-and-error process to optimize performance.

Conveyor systems and automation technologies play a crucial role in modern manufacturing. These systems work together to enhance operational efficiency. For instance, a report by the Association for Advancing Automation indicates that companies using automated conveyor systems experience a 30% increase in productivity. Such integration allows for seamless material flow, reducing manual handling.

Automation systems control the conveyor's operation. They execute tasks like sorting, transporting, and packaging with precision. A well-integrated system can adapt to real-time changes in production needs. According to a recent McKinsey study, 70% of manufacturing leaders believe automation improves equipment reliability. Yet, challenges still exist. Some systems may not sync correctly, leading to delays.

Data analysis plays a vital role in optimizing these systems. Real-time monitoring helps identify bottlenecks in production lines. A study shows that 60% of logistics firms report efficiency gains from data analysis. However, relying solely on technology might lead to overlooking human elements. Balancing automation with skilled labor remains a challenge for many companies.

Conveyor and automation systems offer significant advantages in modern industries. Implementing these technologies can enhance efficiency in manufacturing and logistics. According to a recent industry report, companies that use automated conveyor systems see a productivity increase of up to 30%. These systems streamline operations, reducing the time and effort required for material handling.

One key benefit of automation is the reduction of labor costs. Automated systems handle repetitive tasks, which can lead to a 20% decrease in workforce expenses. However, it’s crucial to note that this relies heavily on the right technology and workforce training. Integration challenges often arise, where employees must adapt to new systems. Failure to manage this transition can result in lower morale and productivity.

Another advantage of conveyors is improved safety in the workplace. By minimizing manual handling, the risk of injury decreases. Data suggests that automation can reduce workplace accidents by as much as 50%. Nevertheless, it is essential to ensure proper maintenance and safety protocols. Neglecting these can lead to machinery failures and workplace hazards, countering the benefits gained.