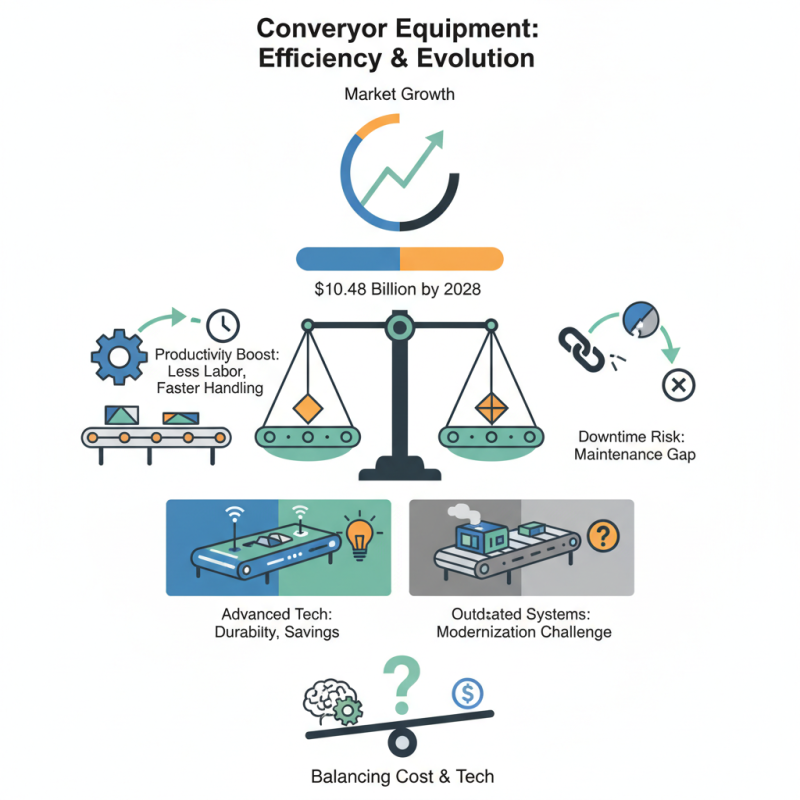

Conveyor Equipment plays a vital role in various industries. It moves materials efficiently and safely across production lines. According to a 2023 report by Grand View Research, the global conveyor systems market is expected to reach $10.48 billion by 2028. This growth indicates the increasing reliance on Conveyor Equipment.

In manufacturing, logistics, and mining, Conveyor Equipment enhances productivity. It minimizes manual labor and reduces handling times. However, this reliance has drawbacks. Equipment failures can lead to significant downtime, affecting overall efficiency. A study by the Material Handling Industry of America noted that companies often underestimate maintenance needs for their Conveyor Equipment.

Investing in advanced technologies could improve durability and reduce costs. Yet, many businesses still cling to outdated systems. The need for modernization is clear, but the challenge remains. Balancing cost and technology is not always straightforward. Understanding these dynamics is crucial for success in today’s competitive landscape.

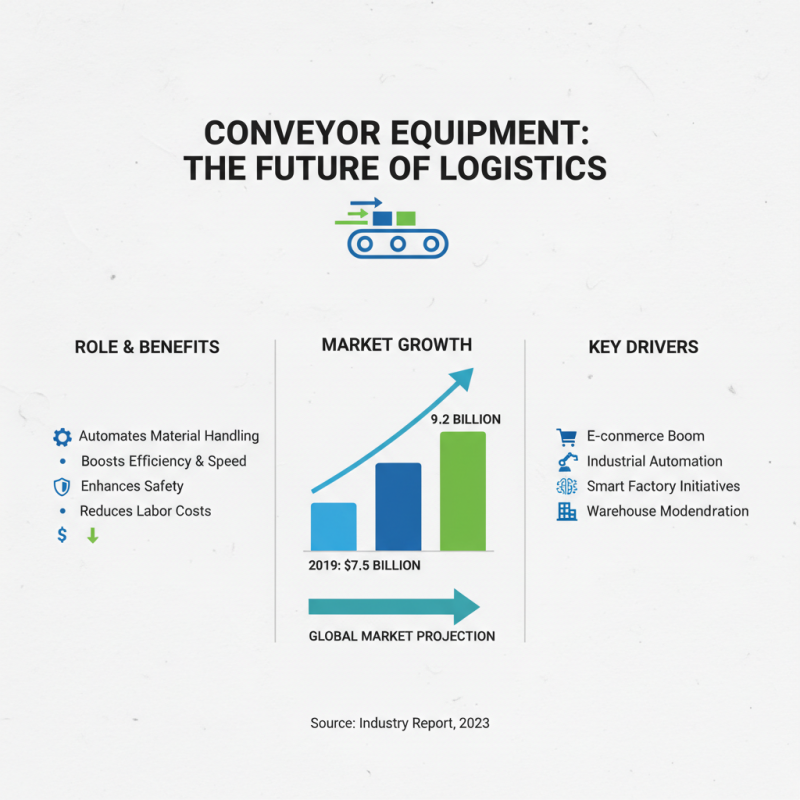

Conveyor equipment plays a vital role in various industries. It automates material handling, improving efficiency and safety in operations. According to a recent report, the global conveyor system market is expected to reach $9.2 billion by 2025. This growth reflects the increasing need for smarter logistics in manufacturing and distribution sectors.

There are several types of conveyor equipment. Roller conveyors are commonly used for heavy loads. Belt conveyors are preferred for moving bulk materials. Modular conveyor systems offer flexibility for diverse tasks. However, choosing the right type can be challenging. Each type serves different purposes and environments. That means analysis is crucial before selection.

**Tip:** Always consider the specific needs of your operation before investing in conveyor equipment. Incorrect choices can lead to inefficiencies and increased costs. Investing in proper training for staff can also enhance safety and performance. Remember, the ideal conveyor system can transform your workflow significantly.

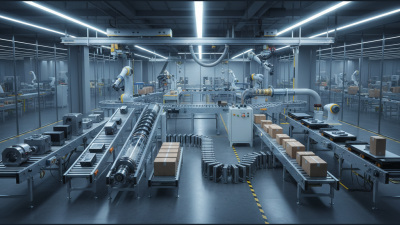

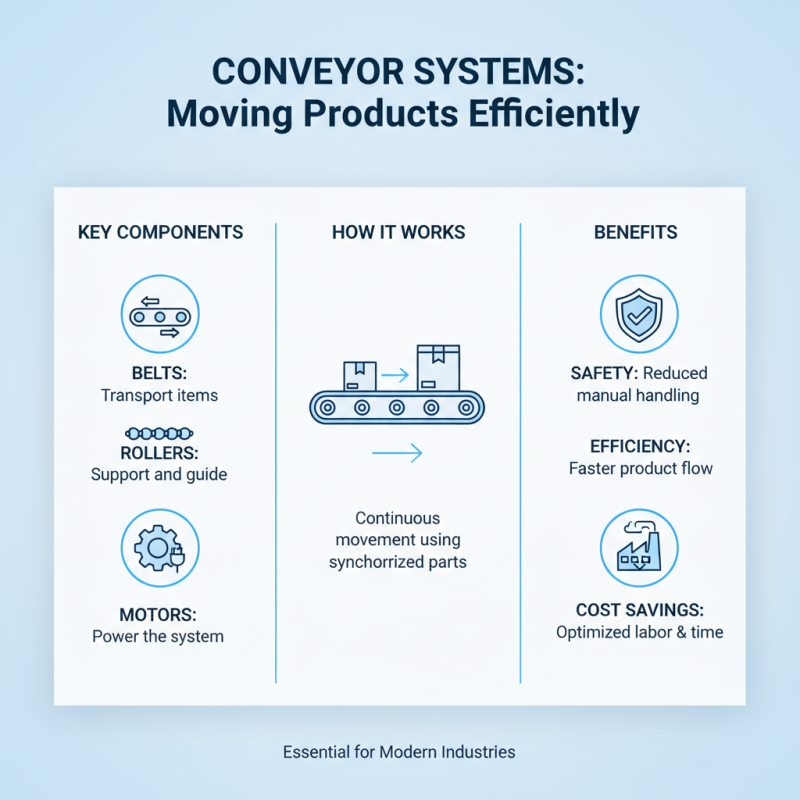

Conveyor systems are essential in many industries. They help move products safely and efficiently. These systems use multiple components to transport items from one place to another. The main parts include belts, rollers, and motors. Each part plays a crucial role in the operation of the conveyor.

The belt is the key element that carries the load. It moves in a continuous loop, driven by the motor. Rollers support the belt and reduce friction. This allows for smoother operation. Sensors can monitor items on the conveyor. They ensure that everything runs smoothly. However, issues can arise. Misalignments can cause jams. Regular maintenance is vital. Skipping checks can lead to costly downtime.

Understanding how conveyor systems operate can improve efficiency. Simple modifications can make a big difference. For example, adjusting the speed can optimize product flow. Yet, overloading can damage belts quickly. This requires a careful balance in operation. Small changes in design may yield significant benefits over time. Continuous learning is the key to maximizing efficiency.

Conveyor equipment plays a crucial role in many industries. In manufacturing, it streamlines production processes. A report by Grand View Research indicates the global conveyor systems market was valued at $7.4 billion in 2021. This value is expected to grow at a CAGR of 4.4% from 2022 to 2030. These systems improve efficiency and reduce labor costs in warehouses and factories.

In the food and beverage industry, conveyor systems ensure hygiene and speed. They transport raw materials and finished products seamlessly. Data from Mordor Intelligence shows that the food conveyor market alone is projected to reach $1.86 billion by 2026. Yet, maintaining these systems is often underestimated. Breakdowns can lead to costly delays, impacting the entire supply chain.

Healthcare facilities also benefit from conveyor equipment. It aids in the swift movement of medical supplies and medicines. An efficient conveyor can minimize human error in such critical environments. However, many facilities overlook routine inspections. This oversight can lead to significant operational disruptions. The challenges in the adoption of conveyor systems highlight the need for continuous improvement and adaptation in various sectors.

| Industry | Conveyor Type | Application | Benefits |

|---|---|---|---|

| Manufacturing | Belt Conveyor | Transporting raw materials and finished goods | Increased efficiency and reduced labor costs |

| Food Processing | Modular Conveyor | Moving packaged food products | High sanitation standards and flexibility |

| Warehouse | Roller Conveyor | Sorting and transporting packages | Improved order fulfillment speed |

| Automotive | Overhead Conveyor | Assembly line transport of vehicles | Space-saving design and improved workflow |

| Construction | Screw Conveyor | Moving bulk materials like cement | Efficient material handling and reduced waste |

Conveyor systems play a crucial role in modern material handling. By streamlining processes, they enhance efficiency across various industries. Reports indicate that automated conveyor systems can improve productivity by up to 50%. This significant boost lowers operational costs and speeds up logistics.

One major advantage is the reduction of manual labor. Workers can focus on higher-level tasks, cutting down the risk of injuries. Data suggests that warehouses using conveyor systems experience a 30% decrease in workplace accidents. Additionally, they are designed to transport various materials, whether small boxes or heavy pallets, offering versatility that manual systems cannot match.

However, not all conveyor systems are flawless. Companies must consider maintenance costs and potential downtime. An inefficient setup can lead to bottlenecks, impacting overall performance. A thorough evaluation of needs is essential. While the benefits are clear, careful planning is key to maximizing value. Attention to detail in installation and operation can prevent issues down the line.

Conveyor equipment plays a crucial role in many industries. Regular maintenance helps ensure smooth operations and longevity. A well-maintained conveyor reduces downtime and increases productivity. Neglecting maintenance can lead to costly repairs and delays.

Common maintenance practices include routine inspections and cleaning. Check for wear and tear on belts and rollers. Lubricate moving parts to prevent friction. Keep the system clear of debris.

Even small blockages can cause major issues. Tracking performance data helps identify potential problems early.

Sometimes, staff may overlook small details during inspections. They might miss minor wear signs or forget to log maintenance tasks. Such oversights can lead to unexpected breakdowns. Training staff is essential. It ensures everyone understands the importance of regular maintenance and their role in it. Encourage open discussions about potential improvements. This can lead to a more efficient maintenance routine.