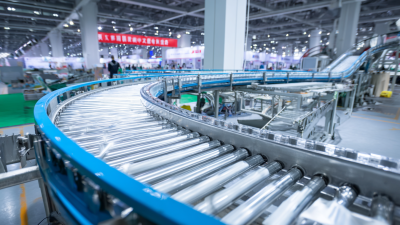

In today's fast-paced manufacturing landscape, the efficiency and effectiveness of production processes are paramount. One key component that has significantly transformed modern manufacturing is the Conveyor Machine. According to a report by Industry Research Insights, the global conveyor systems market is projected to grow at a CAGR of 4.5% from 2021 to 2026, highlighting the increasing reliance on these machines for optimizing operations. As manufacturers strive to enhance productivity and minimize operational costs, the integration of advanced conveyor technologies has become indispensable.

Expert insights underscore the importance of Conveyor Machines in manufacturing setups. Mark Thompson, a leading expert in industrial automation, states, "Conveyor Machines are the backbone of any modern plant, providing seamless material handling that boosts efficiency and reduces downtime." This statement encapsulates the role of conveyor systems in not just transporting materials, but also in enabling a smoother and more synchronized production flow.

As we delve into the intricacies of Conveyor Machines in modern manufacturing processes, it becomes evident that understanding their functionalities and benefits is crucial for organizations seeking to remain competitive in an evolving market. This guide aims to shed light on the various aspects of Conveyor Machines and how they can be leveraged to optimize manufacturing operations.

The evolution of conveyor systems in manufacturing environments has been a game-changer for efficiency and productivity. Historically, conveyor technology began in the late 18th century with simple systems used in mining. Fast forward to the present, modern conveyor systems have integrated advanced automation and robotics, significantly reducing labor costs and enhancing operational speed. According to a report by Research and Markets, the global market for conveyor systems is projected to reach $8.2 billion by 2025, driven largely by the need for automated solutions in manufacturing processes.

In addition to automation, the development of smart conveyor systems equipped with Internet of Things (IoT) capabilities has transformed how industries manage logistics and workflows. These systems can monitor operational performance in real-time and predict maintenance needs, thus minimizing downtime. A study from Deloitte indicates that 60% of manufacturers believe that smart conveyor technology can substantially improve their overall production efficiency, highlighting a tangible shift toward data-driven decision-making in manufacturing operations. This evolution not only streamlines processes but also helps in adapting to the fast-paced market demands.

Conveyor machines play a pivotal role in modern manufacturing processes, offering numerous key benefits that enhance operational efficiency and overall productivity. The integration of advanced technologies, particularly AI-driven predictive maintenance, is transforming how conveyor systems function within production lines. Reports indicate that predictive maintenance can boost factory uptime by as much as 15%, significantly reducing unexpected downtime and related losses. By monitoring conveyor technology in real-time, manufacturers can preemptively address potential issues, ensuring a smoother workflow and maintaining high levels of output.

Furthermore, the application of smart technologies in conveyor systems fosters flexibility and adaptability in production lines. Studies have shown that manufacturers adopting intelligent robotics and interconnected systems benefit from improved operational efficiency and lower operational costs. These systems not only enhance the speed of production but also provide data-driven insights, allowing for optimized supply chains and quality control mechanisms. As factories evolve into smart manufacturing environments, the role of conveyor machines becomes increasingly crucial in maintaining competitiveness in a rapidly changing industrial landscape.

Conveyor technologies have become integral to modern manufacturing processes, driving efficiency and productivity across various industries. Among the innovative types of conveyors, the integration of laser technology and deep learning stands out. Researchers are developing advanced monitoring systems that utilize laser scanning to detect real-time defects on conveyor belts. This not only enhances safety but also minimizes downtime, ensuring continuous operation. Such technologies are particularly beneficial in environments where precision and reliability are paramount, making them vital in sectors like mining and food production.

Another significant advancement is the use of vertical reciprocating conveyors combined with automated guided vehicles (AGVs) and autonomous mobile robots. This synergy boosts operational efficiency by enabling seamless material handling and transportation. As manufacturing moves towards greater automation, these conveyor systems facilitate the smooth integration of robotics, allowing for faster production cycles and improved resource utilization. The transformation brought by these technologies reflects a shift towards smarter, more agile manufacturing practices.

The integration of automation with conveyor systems marks a significant advancement in modern manufacturing processes. Automated conveyor machines streamline the movement of goods, resulting in reduced manual labor and minimizing the risk of human error. By employing robotics alongside conveyor systems, manufacturers can achieve seamless operation, where products are continuously transported, sorted, and packaged without interruptions. This synergy not only enhances the speed of production but also improves overall safety in the workplace by limiting human interaction in high-risk areas.

Additionally, automated conveyor systems enable real-time monitoring and data collection, which allows manufacturers to optimize their operations efficiently. Advanced sensors and AI technology integrated into conveyor systems facilitate predictive maintenance, ensuring that machinery operates at peak performance. This proactive approach reduces downtime, enhances workflow, and increases the longevity of equipment. As a result, companies can respond swiftly to changes in demand while maintaining quality and reducing wastage. Ultimately, the integration of automation into conveyor systems is redefining manufacturing efficiency and helping businesses remain competitive in a rapidly evolving market.

The future of conveyor machine design and application in modern manufacturing processes is poised for significant transformation, driven by advancements in technology and the increasing demand for efficiency. One key trend is the integration of smart technologies, such as IoT-enabled systems that allow real-time monitoring and data analytics. This shift enables manufacturers to optimize workflow, predict maintenance needs, and enhance overall productivity.

Another notable trend is the design of flexible conveyor systems that can adapt to various product types and sizes. These adaptive systems minimize downtime during product changes and improve the versatility of manufacturing operations. Furthermore, innovations in materials, such as lightweight composites, are making conveyors more energy-efficient and easier to maintain.

Tips: Consider investing in conveyor systems with modular designs that can be easily reconfigured as production needs change. Regular training for employees on the latest conveyor technologies can also foster a more efficient work environment, ensuring that your team is equipped to leverage these advancements effectively. Embrace automation solutions that enhance safety and reduce the risk of human error in the manufacturing process.