In today's rapidly evolving industrial landscape, the importance of Conveyor Manufacturing has become increasingly evident, serving as a pivotal component in optimizing operations and enhancing productivity across various sectors. According to a report by IBISWorld, the U.S. conveyor system manufacturing industry is projected to reach an estimated $4.9 billion in revenue by 2025, reflecting a growing acknowledgment of the technology's ability to facilitate efficient material handling processes. As companies strive for greater operational efficiency, the integration of advanced conveyor systems is becoming a cornerstone of modern manufacturing strategies.

Expert in conveyor technology, Dr. Emily Sanders, emphasizes this significance: "The adoption of innovative conveyor solutions not only streamlines processes but also minimizes labor costs and improves workplace safety." Her insights highlight the multifaceted benefits of conveyor systems, which include reducing production time, increasing the speed of goods movement, and enhancing overall supply chain management. As industries broaden their focus on automation and lean manufacturing principles, Conveyor Manufacturing stands at the forefront, driving transformative changes that are essential for meeting the demands of today’s competitive market. This article will explore the pivotal role of conveyor systems in streamlining industrial processes, underscoring their importance for businesses striving to maintain efficiency and profitability in an increasingly complex environment.

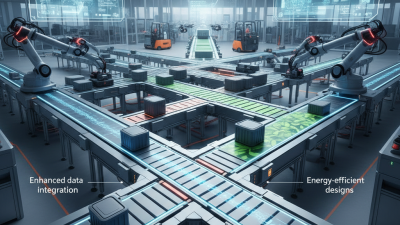

In modern manufacturing industries, conveyor systems play a pivotal role in enhancing productivity and efficiency. These systems are designed to transport materials, components, and finished products seamlessly along production lines, reducing the need for manual handling. By automating the movement of goods, conveyor systems minimize delays, decrease labor costs, and optimize the overall workflow. This is particularly crucial in fast-paced environments where time and precision are of the essence.

Moreover, conveyor systems contribute to improved safety and organization within the manufacturing process. With a continuous flow of materials, the risk of accidents caused by clutter or manual lifting is significantly reduced. Additionally, these systems allow for a more structured layout in factories, facilitating easier monitoring and maintenance of equipment. As industries strive for leaner operations and greater output, the integration of efficient conveyor systems has become not just beneficial but essential for staying competitive in the modern market.

Conveyor manufacturing plays a pivotal role in enhancing operational efficiency within industrial settings. By automating the movement of materials, conveyors minimize manual handling and reduce the likelihood of human error, leading to a more streamlined workflow. This automation not only accelerates production rates but also allows workers to focus on more complex tasks, thus maximizing the use of human resources. The implementation of conveyor systems creates a continuous flow of materials, which is critical for maintaining an efficient production line.

Moreover, the design and technology behind conveyor systems are crucial in optimizing space and reducing operational costs. Customizable conveyor solutions can be tailored to fit specific workflows, accommodating various types of materials and products. This adaptability ensures that factories can achieve a higher output without the need for extensive reconfiguration of their layout. Additionally, conveyors help in minimizing downtime associated with manual transport, which is essential for industries striving to meet tight deadlines and maintain competitiveness in the market. Through these advancements, conveyor manufacturing stands as a cornerstone in driving operational efficiency across diverse industrial processes.

Conveyor systems play a crucial role in enhancing efficiency across various industrial processes. There are several types of conveyor systems, each tailored to meet specific transport and handling needs in different environments. For instance, belt conveyors are widely used in manufacturing and packaging industries for their ability to handle a broad range of materials, from lightweight boxes to heavy products. Roller conveyors, on the other hand, are ideal for transporting items with flat bottoms and can often be found in warehouses and distribution centers.

Additionally, modular conveyors provide flexibility, as they can be easily adjusted and scaled according to production requirements. These systems are particularly useful in assembly lines, where product flow needs to be seamlessly integrated and optimized. Chain conveyors are another option, favored for heavy-duty applications, particularly in automotive and bulk handling sectors, where robustness is essential.

Tip: When selecting a conveyor system, consider not only the type of materials you need to transport but also the layout of your facility. Ensuring that the conveyor system aligns with your production workflow can significantly reduce bottlenecks and enhance overall productivity. Furthermore, regular maintenance and adaptation to emerging technologies can help safeguard the longevity and efficiency of your system.

In the realm of industrial processes, conveyor manufacturing plays a pivotal role in enhancing efficiency and productivity. Recent advancements in conveyor technology have significantly transformed how goods are transported within facilities. According to a report by ResearchAndMarkets, the global conveyor system market is expected to reach $12.3 billion by 2027, showcasing a compound annual growth rate (CAGR) of 4.5%. This growth is largely driven by automation and the increasing need for streamlined operations across various sectors, including manufacturing, logistics, and food processing.

Technological innovations such as smart conveyors, which are equipped with sensors and IoT capabilities, are revolutionizing the industry. These systems not only optimize transportation speed but also provide real-time data analytics that help manufacturers monitor performance and reduce downtime. The integration of AI and machine learning further enhances predictive maintenance, ensuring that any potential issues are addressed before they impact production. This synergy between technology and conveyor systems is crucial for meeting the rising demands of the market.

Tip: When implementing new conveyor systems, consider conducting a thorough analysis of your existing workflows to identify areas where automation can yield the highest returns. Additionally, integrating conveyor systems with your overall supply chain management can drastically improve efficiency.

Another trend is the push toward sustainability in conveyor manufacturing. Manufacturers are now focusing on energy-efficient systems and eco-friendly materials to minimize environmental impact. Implementing energy-saving conveyors not only reduces operational costs but also aligns with global sustainability goals.

Tip: Explore options for conveyors that utilize regenerative drives or lightweight materials, as these can significantly lower your energy consumption and carbon footprint while maintaining productivity.

Custom conveyor solutions play a pivotal role in enhancing operational efficiency across various industries. By tailoring conveyor systems to meet the specific needs of a business, companies can optimize their workflow, reduce manual handling, and minimize downtime. This customization can include variations in belt materials, sizes, and configurations, all aimed at creating a seamless integration with existing processes. For instance, in manufacturing plants, customized conveyors facilitate the movement of products at the right speed and orientation, significantly increasing productivity.

Moreover, different industries, from food processing to automotive assembly, benefit uniquely from custom conveyors. In the food industry, sanitary design and ease of cleaning are essential, while the automotive sector may require heavy-duty systems that can withstand rigorous demands. By addressing these unique requirements, custom conveyor solutions not only improve efficiency but also enhance safety and compliance with industry regulations. This adaptability makes custom conveyors a vital component for businesses looking to innovate and stay competitive in their respective markets.