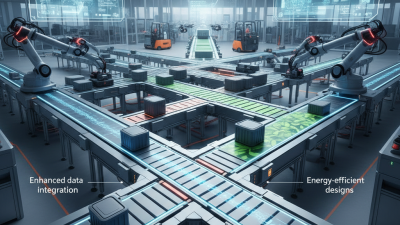

As we approach 2025, the conveyor manufacturing industry stands on the brink of significant transformation, driven by a myriad of trends and innovations. The increasing demands for efficiency and automation in various sectors such as logistics, manufacturing, and food processing are pushing manufacturers to rethink their strategies and adopt cutting-edge technologies. In this ever-evolving landscape, conveyor systems are no longer just simple mechanisms for transporting goods; they are becoming integrated solutions that enhance productivity and streamline operations.

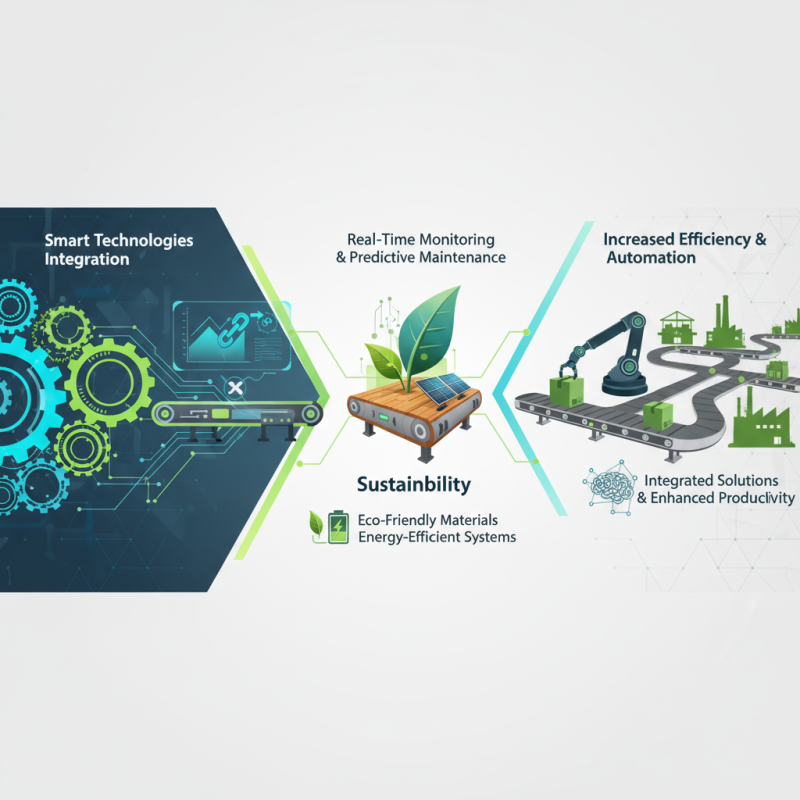

The integration of smart technologies, such as IoT and AI, is revolutionizing conveyor manufacturing, enabling real-time monitoring and predictive maintenance. This shift not only reduces downtime but also optimizes performance, allowing businesses to adapt swiftly to changing market demands. Moreover, sustainability has become a cornerstone of conveyor design, with manufacturers seeking eco-friendly materials and energy-efficient systems that minimize environmental impact.

As we delve into the trends shaping the future of conveyor manufacturing, it’s essential to explore how these innovations can help businesses remain competitive in an increasingly automated world. Understanding these developments will equip industry stakeholders to make informed decisions and drive growth in their operations throughout 2025 and beyond.

The landscape of conveyor manufacturing is evolving rapidly, driven by emerging technologies that are reshaping the industry in 2025. According to a recent industry report from MarketsandMarkets, the global conveyor systems market is projected to reach $9.0 billion by 2025, reflecting an increasing reliance on automation and efficiency in manufacturing processes. As companies seek to streamline operations, innovations such as IoT-enabled systems, machine learning, and advanced robotics are becoming integral components of modern conveyor solutions.

One of the most significant trends is the integration of smart technologies, allowing for real-time monitoring and predictive maintenance. This not only reduces downtime but also enhances overall operational efficiency. A survey conducted by Research and Markets indicated that 70% of industry leaders plan to invest in IoT integration for their conveyor systems within the next two years, underscoring the urgency for businesses to adopt these technologies.

Tips: When considering upgrading your conveyor systems, begin by assessing your operational needs and identify areas where smart technology can provide the most benefit. Additionally, investing in employee training on new technologies will ensure a smoother transition and maximize the return on investment. Remember, prioritizing sustainability through energy-efficient conveyors can also improve your brand appeal while reducing operational costs.

As we approach 2025, sustainability initiatives within conveyor systems are becoming increasingly critical. According to a recent report by the International Conveyor Association, over 70% of manufacturers are prioritizing eco-friendly practices in their operations. One prominent trend is the incorporation of energy-efficient motors, which can reduce power consumption by up to 30%. This shift not only leads to cost savings but also significantly minimizes the carbon footprint of manufacturing processes.

Additionally, the use of recyclable materials in conveyor manufacturing is gaining traction. The Sustainable Manufacturing Institute reports that up to 40% of conveyor systems are now constructed from materials that can be fully recycled at the end of their life cycle. This transition not only addresses waste management concerns but also promotes a circular economy model in the manufacturing sector. As more companies adopt these innovations, we can expect a noticeable shift towards greener operations, positioning the industry to meet future sustainability regulations and consumer expectations.

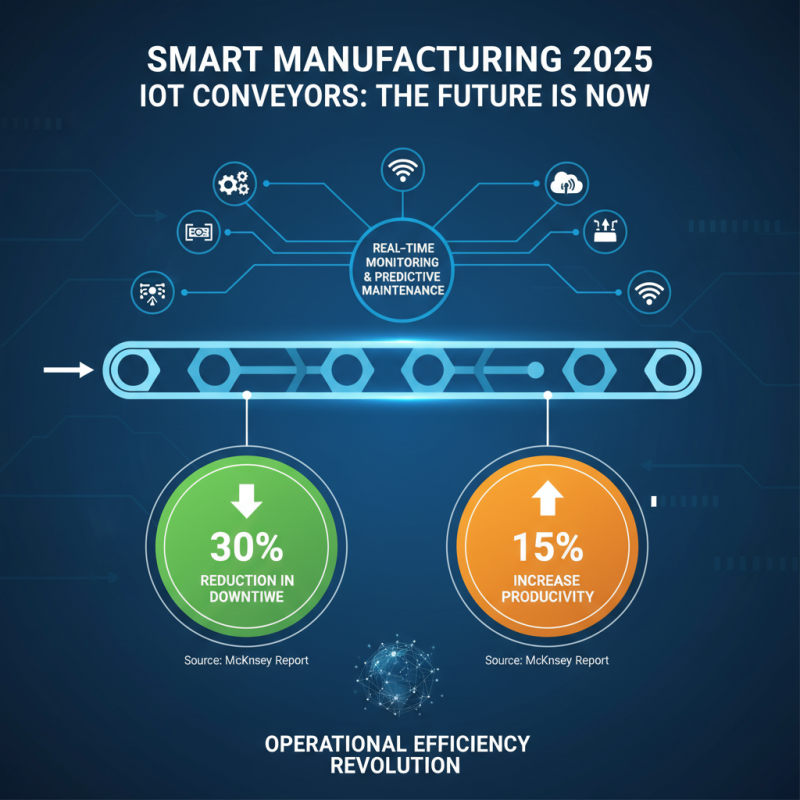

In 2025, the integration of the Internet of Things (IoT) in conveyor systems represents a pivotal shift in the manufacturing landscape, driving significant operational efficiencies. According to a report by McKinsey, adopting IoT technology in manufacturing can lead to a 30% reduction in downtime and a 15% increase in productivity. This trend is largely attributed to real-time monitoring and predictive maintenance capabilities that IoT-enabled conveyors provide, allowing for timely interventions before potential failures disrupt operations.

Moreover, the convergence of IoT with smart automation is set to enhance data collection and processing across conveyor systems. A study by Gartner indicates that by 2025, over 75% of manufacturing companies will utilize IoT solutions as part of their automation processes. This transformation will not only optimize logistics but also enable adaptive routing and efficient resource management. By harnessing the power of IoT, manufacturers can gain actionable insights to improve performance, reduce waste, and streamline operations, positioning themselves strategically in a competitive market.

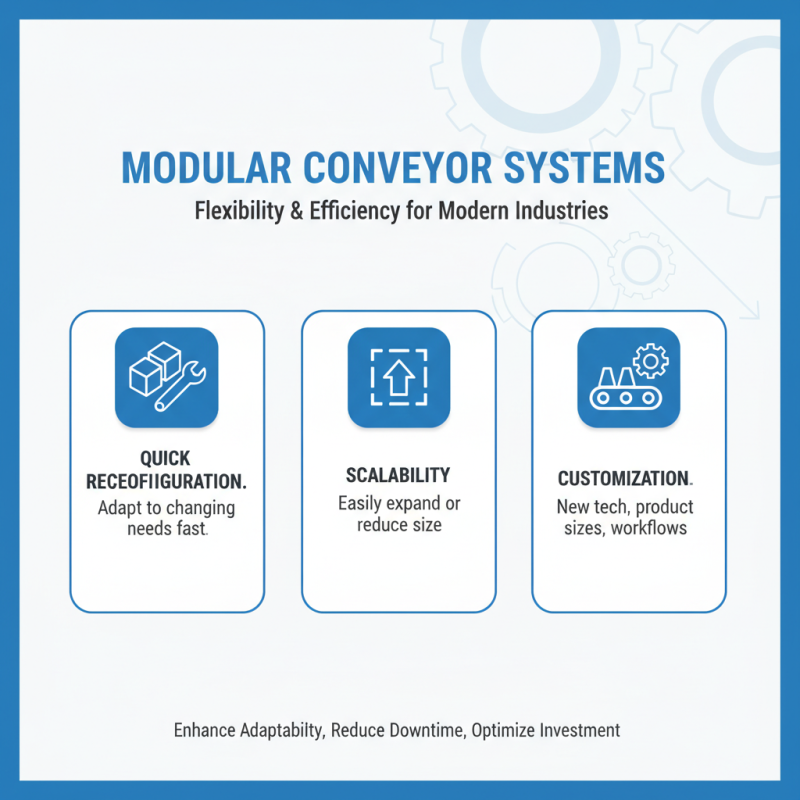

In the evolving landscape of conveyor systems, modular conveyor designs stand out for their flexibility and customization options. As industries seek to enhance efficiency and adapt to dynamic market needs, modular systems allow for quick reconfiguration and scalability. These conveyor systems can be easily modified, enabling businesses to incorporate new technologies, adjust to varying product sizes, and accommodate different workflows without significant downtime or investment.

Tips for implementing modular conveyor designs include conducting a thorough analysis of your current processes to identify areas where flexibility could be beneficial. Consider not only the products and operational requirements but also future growth projections. Engaging with experts who understand the technology can help in customizing solutions that best fit your specific needs.

Another key aspect is to prioritize interoperability when choosing modular components. As the manufacturing environment continues to advance, ensuring that new modules can integrate seamlessly with existing equipment is crucial. This approach not only facilitates expansion but also allows for easier maintenance and quicker upgrades, ultimately leading to a more efficient production line.

The advent of Industry 4.0 has revolutionized conveyor manufacturing processes, enhancing efficiency and opening new avenues for innovation. The integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence, and machine learning into conveyor systems is enabling real-time monitoring and data analytics. This connectivity allows manufacturers to gather valuable insights from the production line, leading to predictive maintenance and minimizing downtime. As a result, companies can optimize their operations and enhance overall productivity, ensuring that their conveyor systems are both efficient and responsive to changing demands.

Moreover, the impact of Industry 4.0 extends beyond mere operational improvements; it drives the development of smart conveyors that can adapt to various materials and workflows seamlessly. Flexible automation enables these systems to alter their configuration based on the specific requirements of the task at hand. With the help of data-driven technologies, manufacturers can implement dynamic routing and sorting mechanisms, which significantly reduce lead times and improve fulfillment rates. As these trends continue to evolve, we can expect conveyor manufacturing to become increasingly intelligent, sustainable, and integral to supply chain processes.