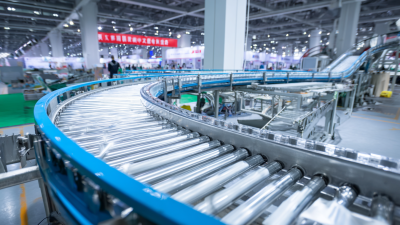

In today's rapidly evolving industrial landscape, Conveyor Technology is taking center stage as a pivotal force in enhancing operational efficiency across various sectors. According to a recent report by Research and Markets, the global conveyor systems market is projected to reach $7.3 billion by 2027, reflecting a compound annual growth rate (CAGR) of 4.8% from 2020. This growth is driven by the increasing demand for automation and streamlined operations in manufacturing, warehousing, and logistics. Advanced conveyor systems not only reduce labor costs but also minimize operational errors, thereby optimizing productivity. As industries embrace Industry 4.0 principles, the integration of smart conveyor technology—incorporating IoT and AI—promises to revolutionize traditional processes, facilitating real-time data analysis and efficient material handling. The future of Conveyor Technology is poised to redefine industry standards, driving innovation and enhancing competitiveness in an ever-changing market.

Conveyor technology has undergone significant advancements, becoming a cornerstone of efficiency in modern industries. Key components such as belts, rollers, and drive systems are crucial in ensuring seamless material handling. Innovations like smart sensors and automated controls are further enhancing productivity, allowing for real-time monitoring and adjustments. These developments not only optimize operations but also contribute to reducing downtime and maintenance costs.

**Tip: When selecting a conveyor system, assess your operational layout and material types to ensure that you choose the most suitable configuration for your needs.** Additionally, consider integrating modular conveyor designs that enable scalability and adaptability as your business grows.

Furthermore, the emergence of eco-friendly materials and energy-efficient motors reflects a shift towards sustainable practices. These innovations not only benefit the environment but also help companies comply with regulations while improving their brand image.

**Tip: Regularly schedule maintenance checks and updates for your conveyor system to enhance its longevity and performance, ensuring that innovations continue to serve your operational needs effectively.** Selecting the right technology today lays the groundwork for a more efficient and profitable future in any industry.

In the realm of modern industries, conveyor systems play a pivotal role in enhancing automation and efficiency. These systems have evolved significantly, integrating advanced technologies such as IoT and AI to streamline operations. By automating the movement of goods, conveyor systems reduce manual labor and minimize human error, leading to increased productivity. The ability to quickly and efficiently transport materials from one point to another not only saves time but also optimizes workflow, allowing companies to focus on value-added tasks.

Moreover, the implementation of conveyor systems contributes to improved workplace safety. With automated transport solutions, the risk of accidents associated with manual handling is significantly decreased. Industries such as manufacturing, logistics, and food processing are particularly benefiting from these technologies, as conveyor systems can be tailored to meet specific operational needs. As businesses continue to seek ways to enhance efficiency and reduce costs, the integration of conveyor technology will undoubtedly remain at the forefront of industrial innovation, driving future advancements in automated processes.

When selecting the right conveyor system for specific industry needs, it’s essential to consider key factors such as load capacity, speed, and material compatibility. According to a report by Research and Markets, the global conveyor system market is expected to grow from $7 billion in 2021 to over $10 billion by 2026, highlighting the increasing reliance on customized solutions across different industries. For example, heavy industries may require robust roller conveyors that can handle significant weight, while food processing facilities might need stainless steel belt conveyors that adhere to stringent hygiene standards.

Additionally, understanding the unique operational requirements of your industry is crucial. A study from the Conveyor Equipment Manufacturers Association (CEMA) shows that automation through conveyor technology can enhance production efficiency by up to 30%. Industries like e-commerce have specific needs for high-speed sorting systems, whereas manufacturing sectors may focus on seamless integration with existing machinery. Thus, conducting a thorough analysis of your operational demands will help in selecting the best conveyor system that not only improves workflow but also drives long-term profitability.

Integrating conveyor technology within smart manufacturing solutions is set to redefine industry efficiency and productivity. As highlighted in recent analyses, the global smart factory market is projected to reach significant growth fueled by advancements in technologies such as the Industrial Internet of Things (IIoT), digital twins, and robotics. In fact, the friction roller conveyor market alone is expected to reach USD 2,381 million by 2035, demonstrating a compound annual growth rate (CAGR) of 6.1%. This rapid evolution underscores the critical role that conveyor systems play in the logistics and supply chain sectors, enhancing automation and reducing operational costs.

Moreover, leading industries are increasingly turning to artificial intelligence to harness data-driven insights for improved decision-making processes. Automation investments are particularly prominent in food manufacturing, with 78% of consumer packaged goods companies prioritizing productivity enhancements amid labor shortages and rising costs. Smart manufacturing initiatives exemplify how these technologies can work in concert to not only digitize operations but also streamline workflows, ultimately paving the way for a new era of manufacturing that prioritizes agility and sustainability.

The conveyor technology sector is witnessing transformative advancements aimed at sustainability and efficiency. Innovations in conveyor systems, driven by a commitment to eco-friendly practices, are reshaping industries such as mining and logistics. For instance, the growing focus on sustainable practices in bauxite mining highlights how conveyor technology can minimize environmental impacts while enhancing productivity. As companies adopt more sustainable practices, they increasingly rely on advanced conveyor systems to streamline operations and reduce waste.

Tips: Consider investing in modular conveyor systems that can be easily adapted for various applications, contributing to sustainability through longevity and versatility. Additionally, explore technologies such as low-power AC drives to optimize energy consumption and improve overall system efficiency.

The conveyor belt market in Europe is predicted to grow significantly by 2033, driven by trends in automation and smart logistics. As industries worldwide embrace these technologies, the emphasis on reducing carbon footprints while increasing operational efficiency becomes paramount. Recent innovations demonstrate that conveyor systems can meet these dual demands, integrating advanced materials and designs that push the boundaries of traditional transport methods.

Tips: Look for conveyor systems that integrate IoT capabilities for real-time monitoring and optimization, ensuring that your operation remains efficient and environmentally conscious. Investing in systems with predictive maintenance features can also help in extending the lifespan of the equipment, further contributing to sustainability efforts.

| Feature | Current Trend | Future Outlook | Impact on Industries |

|---|---|---|---|

| Automation | Increased use of robotics | Fully automated systems | Higher efficiency and lower costs |

| Sustainability | Eco-friendly materials | Circular economy practices | Reduced carbon footprint |

| Modularity | Customizable systems | Flexible configurations | Adaptability to market changes |

| Smart Technology | IoT integration | AI-driven operations | Enhanced decision-making processes |

| Speed & Efficiency | Faster conveyor belts | Optimized throughput | Increased productivity |