In the rapidly evolving landscape of modern manufacturing, the role of Assembly Conveyor Systems has become increasingly crucial for enhancing operational efficiency and productivity. According to a report by Markets and Markets, the global conveyor system market is projected to reach $10.9 billion by 2025, driven by the need for automated solutions that reduce labor costs and improve production timelines.

Assembly Conveyor Systems not only streamline the assembly process but also integrate advanced technologies such as IoT and AI, allowing for real-time monitoring and optimization. With manufacturers facing mounting pressure to adapt to changing consumer demands and to maintain competitive edges, unlocking the full potential of these systems is imperative.

As we explore the future of Assembly Conveyor Systems, it becomes evident that their strategic implementation will be vital for driving innovation and sustainability in the manufacturing sector.

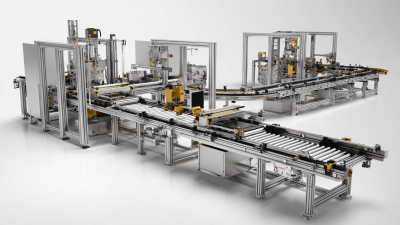

Assembly conveyor systems are a crucial component in modern manufacturing, designed to streamline production processes and enhance efficiency. These systems facilitate the movement of products and components along a defined path, allowing for a seamless flow of materials between different stages of assembly. By reducing manual handling and ensuring that parts are delivered exactly where they are needed, assembly conveyors minimize bottlenecks and increase overall productivity.

Understanding the basics of assembly conveyor systems involves recognizing the different types and configurations available. Common types include belt conveyors, roller conveyors, and modular systems, each tailored to accommodate varying product sizes and weights. Moreover, the integration of automation and smart technologies, such as sensors and robotics, has revolutionized these systems, enabling predictive maintenance and real-time monitoring. As manufacturers seek to optimize their operations, mastering the fundamentals of assembly conveyor systems becomes essential for driving efficiency and staying competitive in an ever-evolving industry.

In the rapidly evolving landscape of modern manufacturing, assembly conveyor systems play a crucial role in optimizing production efficiency. Recent industry reports indicate that integrating advanced conveyor designs leads to a significant reduction in production time—by as much as 30% in some cases. Key features that enhance efficiency in these systems include modular designs, automation, and smart technology integration. Modular conveyors allow for flexibility in layout, making it easier to adapt to different production processes without extensive downtime.

To further improve efficiency, manufacturers are increasingly adopting automated conveyor systems equipped with sensors and IoT capabilities. These technologies not only streamline operations but also provide real-time data analytics, enabling manufacturers to monitor performance and predict maintenance needs. A survey by the Manufacturing Institute revealed that companies employing smart conveyor systems witness a 25% increase in operational productivity.

Tips: To maximize the benefits of modern conveyor systems, consider investing in training for your employees on new technology. Additionally, regularly evaluate your conveyor layout to ensure it meets current production requirements, as an optimized path can significantly reduce cycle times.

The future of assembly conveyor systems in modern manufacturing is increasingly intertwined with automation, as companies seek strategies to streamline their conveyor operations. Leveraging automation not only enhances efficiency but also significantly reduces operational costs. According to recent studies, organizations implementing supply chain automation can achieve up to a 30% increase in overall efficiency while minimizing waste and delays.

One of the most promising advancements is the integration of advanced data analytics and machine learning into conveyor systems. This technology facilitates real-time monitoring and adjustments, allowing manufacturers to preemptively address bottlenecks and optimize production workflows. Additionally, automated warehouses continue to demonstrate the benefits of this approach, where cutting-edge technologies are seamlessly orchestrated to manage inventory, packaging, and delivery, resulting in faster turnaround times and lower operational costs.

Furthermore, the aviation industry’s innovative baggage management solutions serve as a compelling example of automation in action. By automating baggage handling, airlines have reported a remarkable increase in processing speed, which enhances the overall passenger experience. This trend highlights the critical role of automation not only in traditional manufacturing settings but also across various sectors, proving that the future of assembly conveyor systems will be defined by efficiency and innovation.

| System Type | Automation Level | Efficiency Improvement (%) | Implementation Cost (USD) | Average ROI (months) |

|---|---|---|---|---|

| Modular Conveyor System | High | 30% | 15,000 | 6 |

| Automated Guided Vehicle | Medium | 25% | 50,000 | 12 |

| Belt Conveyor System | Low | 15% | 10,000 | 8 |

| Overhead Conveyor System | Medium | 20% | 30,000 | 10 |

| Skatewheel Conveyor | Low | 10% | 5,000 | 4 |

The integration of smart technologies into assembly conveyor systems represents a significant shift towards enhanced efficiency in modern manufacturing. Real-time monitoring and control, powered by advancements such as the Internet of Things (IoT) and artificial intelligence (AI), enable manufacturers to optimize their operations dynamically. These technologies revolutionize data collection and analysis, allowing for immediate adjustments to manufacturing processes based on real-time feedback, thereby minimizing downtime and maximizing productivity.

Moreover, the focus on sustainable practices is aligning with the rise of Industry 5.0. Smart sensors and IoT applications are not only facilitating efficient supply chain management but also promoting eco-friendly approaches by reducing waste and energy consumption. By harnessing data-driven insights, manufacturers can make informed decisions that contribute to environmental sustainability while improving their operational efficiencies. Embracing these smart technologies is not just about keeping pace with innovations but also about setting the stage for a more agile, responsive, and responsible manufacturing landscape.

As manufacturing evolves, the integration of sustainable practices into conveyor system development is becoming increasingly critical. The shift towards environmental responsibility is shaping industry trends, prompting manufacturers to rethink their conveyor systems to enhance energy efficiency and reduce waste. Innovations in materials and design are moving towards greener solutions, aligning with broader goals of sustainability in manufacturing processes.

The demand for efficient and sustainable conveyor systems is underscored by current market trends. For instance, significant investments in the sector indicate a commitment to creating more environmentally friendly operations. Companies are focusing on leveraging advanced technologies, such as AI, to improve energy management and operational efficiency while meeting carbon neutrality targets. This not only addresses pressing environmental concerns but also positions businesses favorably in a competitive marketplace where sustainability is increasingly valued.