In today's fast-paced logistics environment, the importance of an efficient Tire Conveyor And Storage Line cannot be overstated. According to a report by the Material Handling Industry Association, improving material handling efficiency can lead to a 30% increase in productivity and a significant reduction in operational costs. As the global tire manufacturing market steadily expands, projected to reach $300 billion by 2025, the need for advanced conveyor systems and optimized storage solutions becomes crucial for companies to stay competitive. This blog aims to provide a comprehensive guide filled with expert tips and insights into designing and implementing efficient Tire Conveyor And Storage Line solutions, ensuring that your logistics performance reaches its peak while meeting the growing demands of the industry.

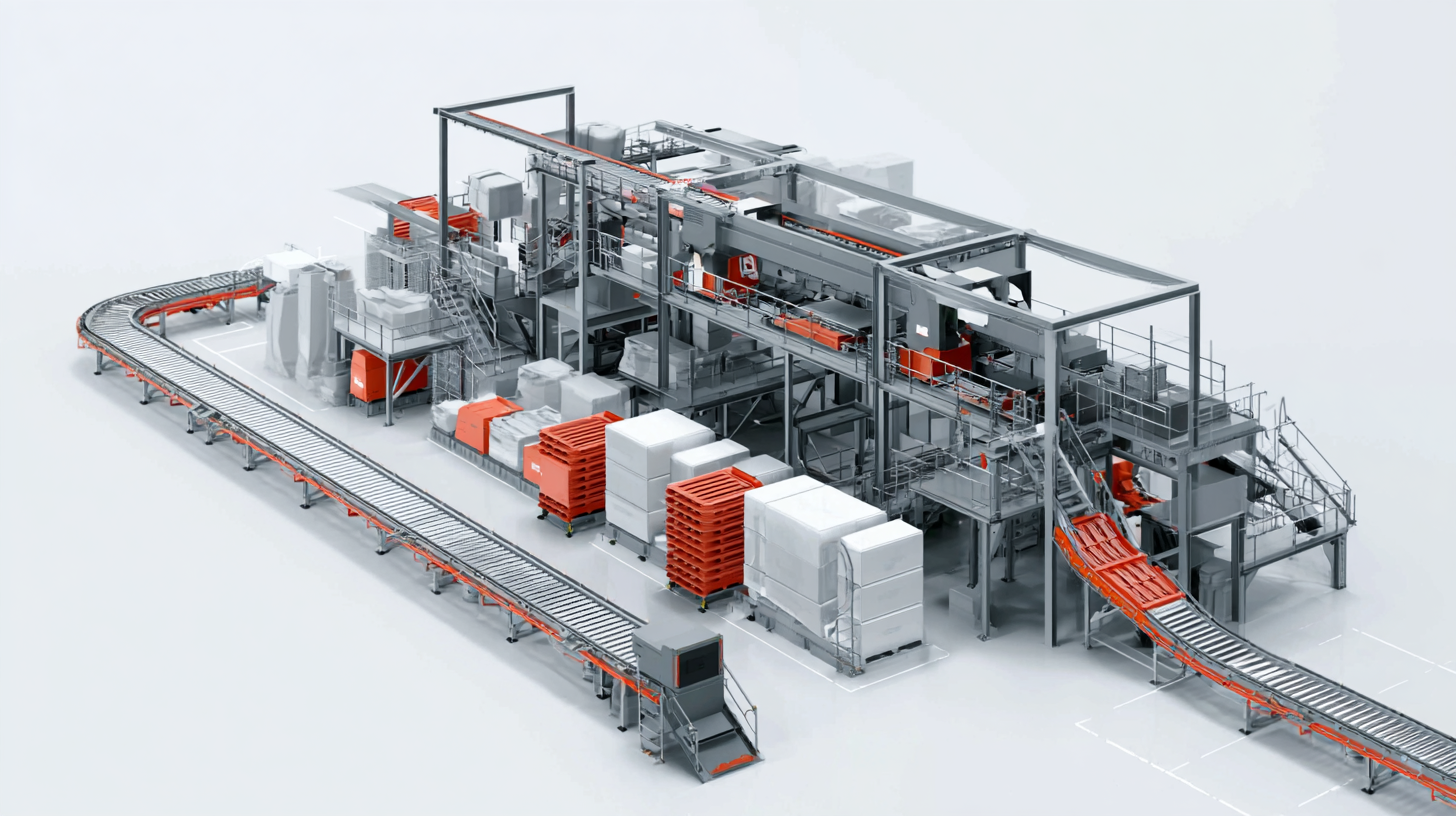

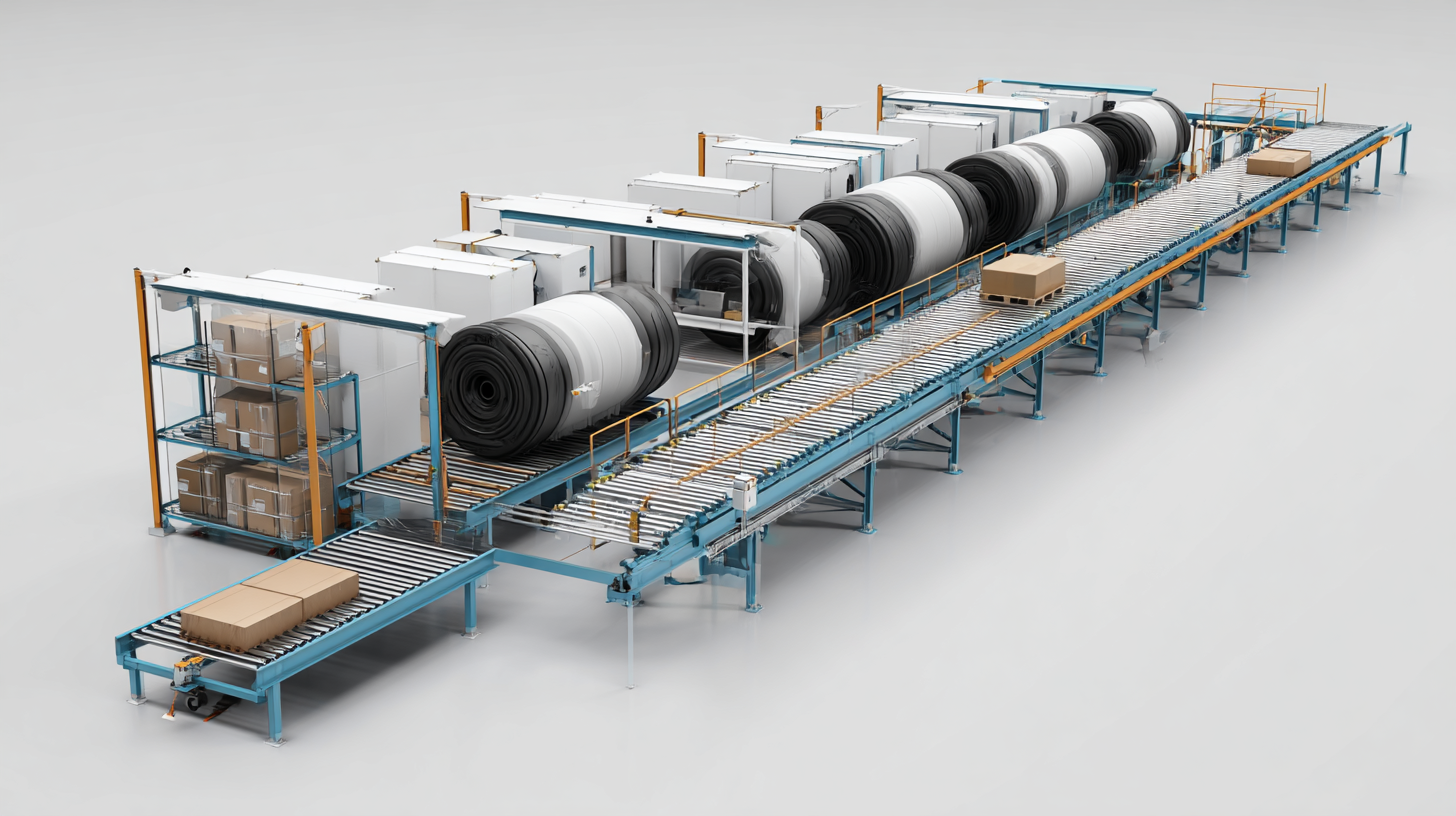

Tire conveyor systems play a crucial role in optimizing logistics performance, especially in industries where efficient tire handling is essential. These systems streamline the movement of tires from production to storage and distribution, reducing manual labor and minimizing the risk of damage. By utilizing automated tire handling solutions, businesses can ensure that their logistics processes are not only faster but also more reliable.

Modern tire conveyor systems are designed to handle varying tire sizes and weights, accommodating the diverse needs of tire manufacturers and distributors.

Tire conveyor systems play a crucial role in optimizing logistics performance, especially in industries where efficient tire handling is essential. These systems streamline the movement of tires from production to storage and distribution, reducing manual labor and minimizing the risk of damage. By utilizing automated tire handling solutions, businesses can ensure that their logistics processes are not only faster but also more reliable.

Modern tire conveyor systems are designed to handle varying tire sizes and weights, accommodating the diverse needs of tire manufacturers and distributors.

In Australia, the demand for advanced tire logistics is rising, leading to innovative solutions like specialized tire handlers that enhance operational efficiency. With the growing importance of tire logistics in this region, businesses are focusing on integrating advanced conveyor technologies to optimize their supply chains. This shift not only improves the speed of tire delivery but also helps in better inventory management, aligning with the overarching goal of achieving seamless logistics performance. Understanding the basics of tire conveyor systems allows companies to make informed decisions on the technologies that best suit their operational needs.

Efficient tire storage solutions play a pivotal role in enhancing logistics performance for tire management operations. As the tire storage rack market is projected to grow significantly due to increasing tire inventory needs, businesses must adopt streamlined processes to handle these demands. Investing in optimized tire storage systems not only maximizes space but also ensures quick and easy access to tires, which can significantly reduce retrieval times.

Tip: Implement a first-in-first-out (FIFO) approach when arranging tire inventory. This strategy helps maintain the health of stored tires and ensures that older stock is used first, minimizing waste and maximizing efficiency.

Moreover, integrating advanced technology, such as cloud-based inventory management systems, can further streamline tire storage operations. These systems offer real-time tracking and analytics, enabling businesses to maintain accurate inventory levels and reduce costs associated with overstocking or stockouts.

Tip: Regularly review and analyze tire storage data to identify trends and optimize inventory management strategies. Leveraging insights from data can enhance decision-making and drive operational efficiency.

In the rapidly evolving world of logistics, innovative technologies are crucial for enhancing the performance of tire conveyor and storage lines. As manufacturers and distributors seek to streamline operations, the adoption of automation and artificial intelligence (AI) has emerged as a game changer. Automated guided vehicles (AGVs) can autonomously transport tires across facilities, minimizing manual labor and reducing the risk of injuries. Furthermore, advanced conveyor systems equipped with smart sensors allow for real-time monitoring of tire movements, ensuring efficiency and reducing bottlenecks.

Another innovative approach gaining traction is the integration of IoT (Internet of Things) technology in logistics. By connecting various components of the tire storage and conveyor systems, operators can gain valuable insights into inventory levels and performance metrics. This data-driven approach enables proactive maintenance, which minimizes downtime and maximizes throughput. Additionally, predictive analytics can forecast demand, allowing manufacturers to optimize their supply chain and reduce costs. By leveraging these technologies, businesses can not only improve the overall efficiency of their tire logistics but also enhance customer satisfaction through timely deliveries and better service.

This chart illustrates the efficiency metrics of various tire conveyor and storage solutions in terms of throughput, maintenance time, and energy consumption. These metrics are crucial for optimizing logistics performance in tire handling.

Effective maintenance and optimization of tire handling systems are crucial for enhancing logistics performance in the tire industry. Regular inspections play a vital role in identifying potential issues before they escalate. Establishing a routine maintenance schedule can help ensure that all components, from conveyors to storage systems, operate seamlessly. This proactive approach minimizes downtime and reduces repair costs while extending the lifespan of the equipment.

Additionally, leveraging technology such as automation and IoT sensors can significantly improve the efficiency of tire conveyor systems. By monitoring performance metrics in real-time, businesses can optimize their operations and make data-driven decisions. Implementing predictive maintenance strategies allows companies to reduce unexpected failures and streamline operations, ultimately leading to improved throughput and safety in tire handling. Balancing regular maintenance with innovative technologies creates a resilient and efficient tire handling environment that caters to the demands of modern logistics.

| Aspect | Best Practices | Maintenance Frequency | Optimization Techniques |

|---|---|---|---|

| System Design | Design for modularity and scalability | Annually | Implement predictive analysis for layout adjustments |

| Conveyor Speed | Adjust speed based on load and distance | Monthly | Use variable frequency drives (VFDs) |

| Sensors and Automation | Integrate IoT sensors for real-time data | Quarterly | Utilize machine learning for predictive maintenance |

| Employee Training | Regular training on new equipment and processes | Biannually | Create a knowledge-sharing platform |

| Spare Parts Management | Keep critical spare parts in stock | Ongoing | Implement just-in-time inventory systems |

In the fast-evolving landscape of tire logistics management, the implementation of efficient conveyor and storage line solutions has become crucial for optimizing operational performance. Recent industry insights show that more than 66% of automotive CEOs recognize the importance of leveraging advanced logistics solutions to enhance supply chain efficiency. Effective tire logistics management not only ensures timely delivery but also minimizes operational bottlenecks, leading to substantial cost savings.

Case studies from various companies demonstrate the successful integration of 'phygital' solutions—combining both physical and digital elements—to adapt to modern logistical challenges. For instance, implementing automated tire conveyor systems has shown to reduce handling time by up to 30%, significantly improving turnover rates. Moreover, AI-driven analytics tools facilitate real-time tracking and predictive maintenance, enabling firms to manage their tire inventories proactively. These innovations align well with the broader trends of customer transformation in the industry, illustrating the potential for enhanced responsiveness and efficiency in tire logistics management.