As we approach 2025, the conveyor manufacturing industry is poised for significant advancements influenced by various emerging trends, particularly in the realm of import and export certification. According to a report from Global Market Insights, the conveyor systems market is expected to surpass $13 billion by 2025, driven by increasing automation in manufacturing and logistics. With heightened global competition, the importance of compliance with international certification standards has become paramount. Emerging economies are ramping up their production capacities while adhering to best practices in conveyor manufacturing to ensure product safety and reliability. Consequently, businesses seeking to expand their markets must navigate the complexities of these certifications to enhance their operational efficiencies and maintain competitive edge. This blog will explore these trends and their implications for the conveyor manufacturing sector, shedding light on how companies can prepare for future challenges.

The conveyor manufacturing industry is poised for significant transformation by 2025, driven by rapid technological advancements and growing demands for efficiency. Key innovations include the integration of advanced automation and digital technologies, which McKinsey predicts will be crucial for supply chain optimization. It is projected that by 2025, over 60% of new industrial equipment will incorporate these technologies, enhancing the speed and accuracy of operations in conveyor systems.

Furthermore, sustainability will play a pivotal role in shaping conveyor technology. With increasing environmental regulations, manufacturers are focusing on developing eco-friendly solutions that minimize energy consumption and waste. Innovations in materials, such as using recycled components in conveyor systems, are gaining traction, aligning with the sustainable practices highlighted in various industry reports. These trends reflect a broader shift in the manufacturing sector towards greener technologies, ensuring that conveyor systems not only meet current demands but are also prepared for future challenges. This evolution emphasizes the importance of adaptability in manufacturing processes to remain competitive in an ever-changing marketplace.

The conveyor manufacturing industry is undergoing a significant transformation as it shifts towards more sustainable practices. As we approach 2025, manufacturers are adopting eco-friendly materials and technologies to minimize their environmental impact. This trend is driven by a growing awareness of global sustainability issues and the need for organizations to reduce their carbon footprints. Innovative materials, such as recycled plastics and biodegradable alternatives, are being utilized to create more efficient conveyor systems. These advancements not only support environmental goals but also enhance the durability and longevity of the products.

In addition to material choices, energy efficiency is becoming a focal point in conveyor manufacturing. Companies are investing in smart technology solutions that optimize energy consumption throughout the conveyor's lifecycle. This includes the integration of IoT devices that monitor performance and provide data for continuous improvement. By reducing energy usage and incorporating renewable energy sources, manufacturers can further align with sustainability goals. This proactive approach is not only beneficial for the planet but can also lead to significant cost savings for companies in the long run, creating a win-win situation in the quest for greener manufacturing processes.

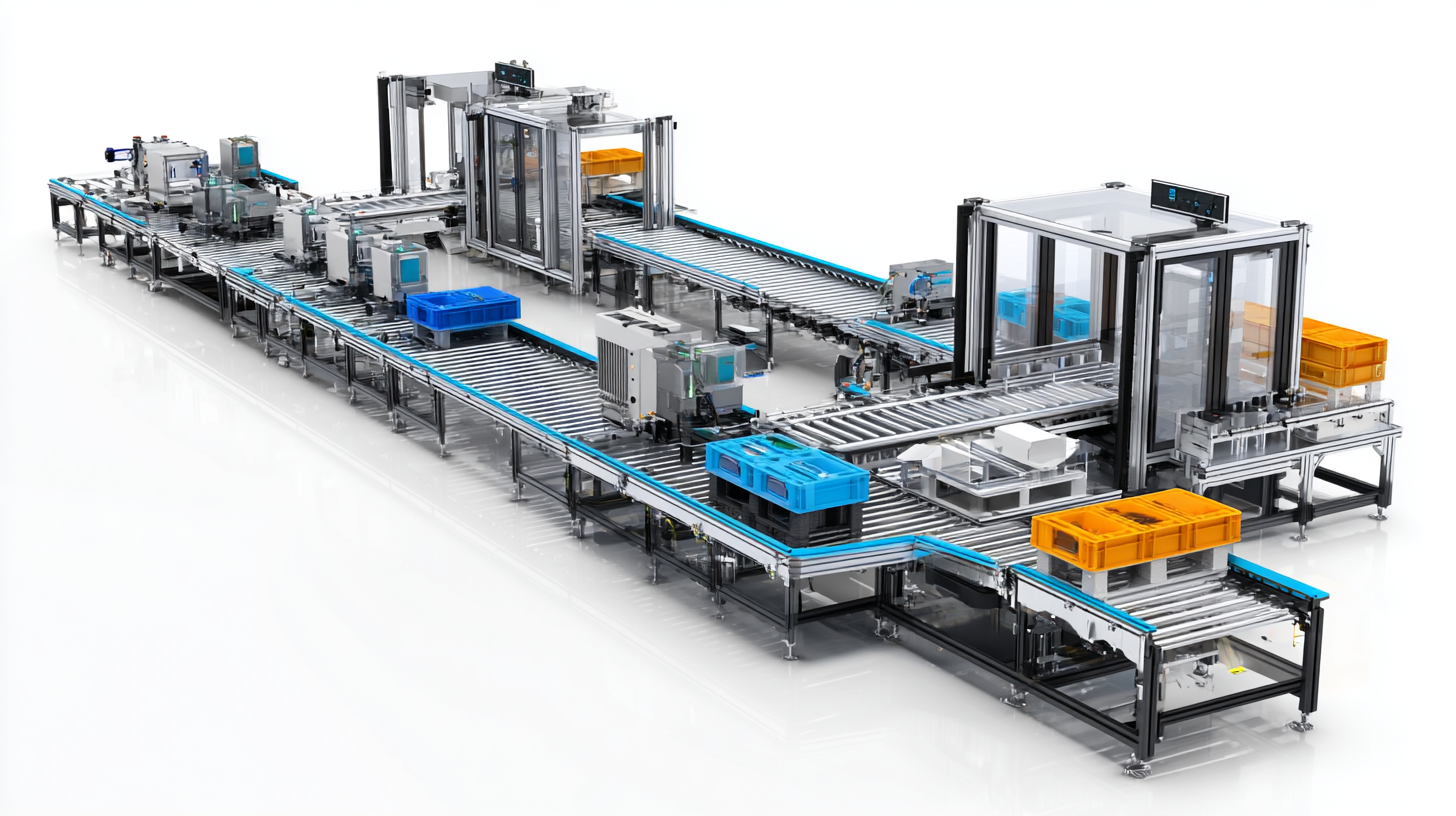

As we look towards 2025, the conveyor manufacturing industry is poised for a significant transformation driven by automation and artificial intelligence (AI) integration. These advancements are reshaping how conveyor systems operate, enhancing efficiency, safety, and adaptability in production environments. By incorporating AI algorithms, conveyor systems can now predict maintenance needs, optimize workflows, and even adapt to varying product specifications in real time, delivering unprecedented flexibility to manufacturers.

Moreover, automation is evolving beyond simple mechanization of tasks. Smart conveyor systems equipped with sensors and IoT technologies are enabling real-time data collection and analytics. This connectivity allows for a more responsive manufacturing process, where issues can be detected and addressed proactively, minimizing downtime. The ability to harness data not only improves operational efficiency but also supports sustainability efforts by reducing waste and energy consumption. As the industry transitions towards these smart solutions, manufacturers who embrace automation and AI will likely position themselves as leaders in an increasingly competitive landscape.

As conveyor manufacturing continues to evolve, the focus on emerging materials for enhanced durability is becoming increasingly crucial. In 2025, manufacturers are prioritizing advanced composites and high-performance polymers that not only withstand wear but also resist corrosion and environmental challenges. Materials like thermoplastic elastomers and specially formulated polyurethanes are gaining traction, as they provide flexibility and strength while minimizing downtime due to maintenance.

Furthermore, the integration of smart materials that can respond to environmental conditions is set to revolutionize the industry. For instance, conveyors with self-healing capabilities or those that can adapt based on load and temperature can significantly extend service life and efficiency. These innovations not only lead to cost savings over time but also contribute to a more sustainable approach in manufacturing processes by reducing waste. As we move closer to 2025, the incorporation of these advanced materials will mark a significant leap forward in the durability and functionality of conveyor systems.

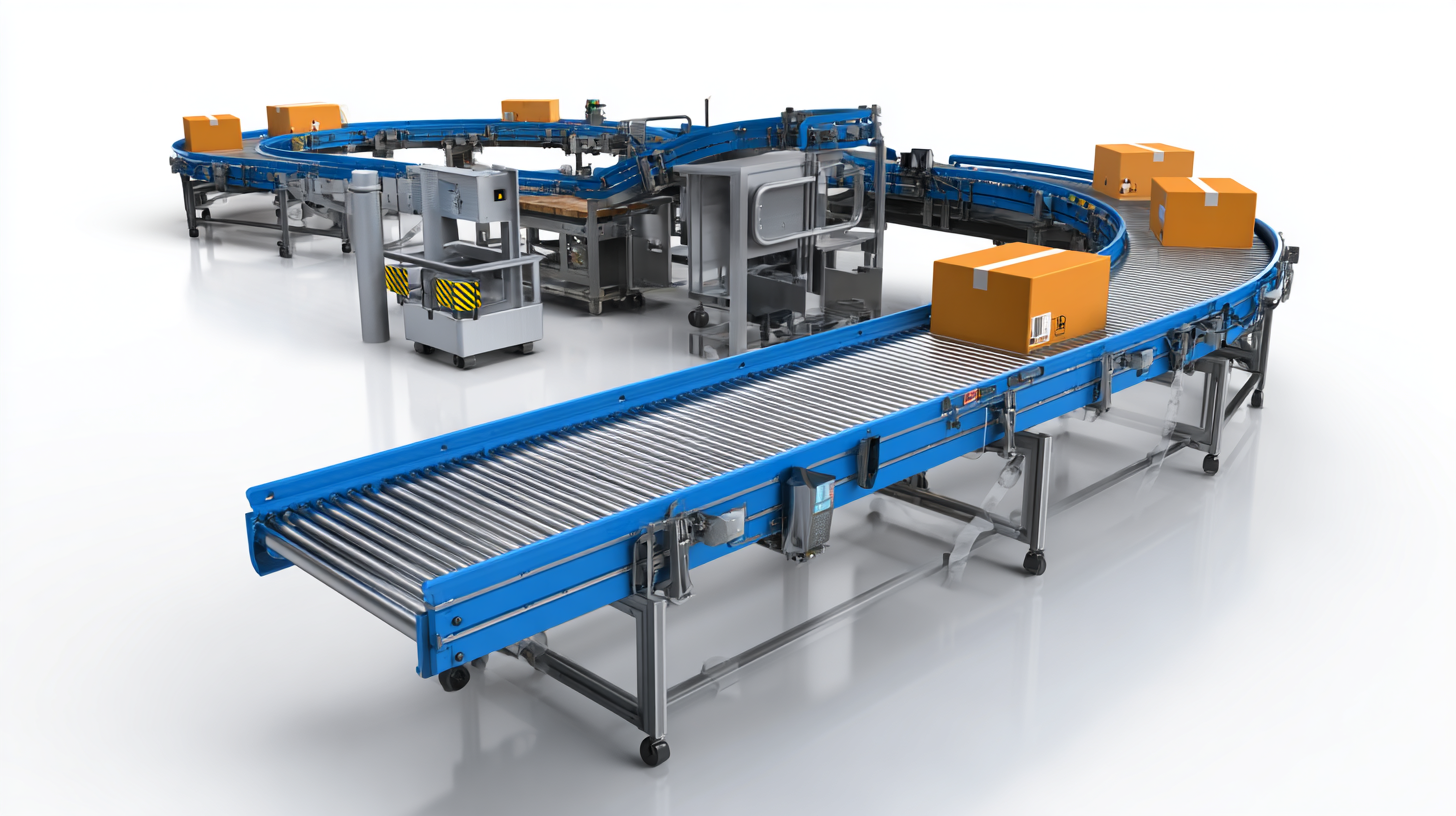

As we move toward 2025, the conveyor manufacturing industry is witnessing a significant shift toward customization and modular designs. Businesses are increasingly seeking conveyor systems that can be tailored to their specific operational needs, allowing for enhanced efficiency and flexibility in their production lines. The demand for bespoke solutions is driving manufacturers to innovate, offering a variety of components that can be configured to fit unique workflows. This trend not only maximizes performance but also helps companies save costs by avoiding the purchase of entirely new systems during upgrades.

Modular conveyor designs are gaining traction as well, allowing for easier installation, maintenance, and scalability. These systems can be expanded or reconfigured with minimal downtime, adapting to changes in product lines or production processes. The ability to interchange modules simplifies repairs and reduces the need for specialized tools, making it easier for operators to maintain workflow continuity. Additionally, this approach facilitates the integration of advanced technologies, such as IoT sensors and automation, enhancing overall operational intelligence and productivity. As customization and modularity continue to dominate the landscape, manufacturers are poised to meet the evolving demands of a dynamic market in 2025 and beyond.