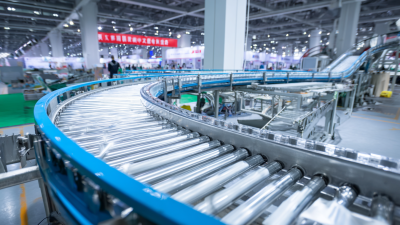

The landscape of industrial automation is on the cusp of transformation, with Conveyor Technology playing a pivotal role in this evolution. As indicated by a recent report from Research and Markets, the global conveyor system market is projected to reach $7.2 billion by 2027, growing at a CAGR of 4.1% from 2022. This growth underscores the rising importance of efficiency and speed in manufacturing and distribution processes.

Innovations in conveyor systems are enabling industries to enhance operational workflows and minimize downtime, thereby significantly reducing costs and improving productivity. The integration of advanced technologies such as IoT, AI, and robotics is further optimizing conveyor solutions, making them smarter and more adaptive to dynamic operational demands. As industries embrace automation, the capabilities of Conveyor Technology are becoming increasingly vital, setting the stage for a revolution across various sectors, from logistics to manufacturing.

The evolution of conveyor technology is rapidly transforming various industries, driven by key innovations that enhance efficiency, safety, and automation. One significant advancement is the integration of IoT-enabled systems which allow for real-time monitoring and management of conveyor operations. This connectivity not only streamlines processes but also empowers operators to make informed decisions based on data analytics, reducing downtime and improving throughput.

In sectors such as aviation and mining, the impact of these technological improvements is particularly noticeable. For example, in baggage management for airlines, automated conveyor systems equipped with advanced tracking features are optimizing the handling and transport of luggage, resulting in increased passenger satisfaction and operational efficiency. Similarly, in the mining industry, the adoption of automated conveyor technologies is set to revolutionize mining farms by facilitating the quick and efficient movement of materials while adhering to sustainability goals. These innovations are paving the way for a more automated and productive future across multiple sectors.

The integration of smart sensors in conveyor technology is set to transform the efficiency of automated systems across various industries. According to industry reports, the global smart gardening systems market is projected to grow significantly, from approximately $339.73 million in 2025 to around $2.44807 billion by 2033. This escalating demand underlines the vital role of automation in industries seeking enhanced operational capabilities. Advances in vertical conveyor systems are notable, as they evolve from basic material handling equipment into sophisticated, predictive maintenance tools that capitalize on real-time data.

In the context of logistics, companies are recognizing the necessity for smarter systems, reflected in the forecasted growth of conveyor belt markets. By 2033, this sector is expected to expand from $111.56 million in 2025 to over $114.91 million, driven by a stable CAGR of 3.0%. This trend illustrates a broad shift towards integrating smart technologies that streamline production processes, reduce maintenance costs, and ultimately drive productivity in an increasingly automated world. Such innovations represent a pivotal moment in industry practices, where the implementation of intelligent systems can significantly enhance both efficiency and strategic decision-making.

The integration of AI and machine learning in conveyor technology is poised to transform various industries by enhancing operational efficiency and reliability. According to a report by Market Research Future, the global conveyor systems market is projected to reach $8.4 billion by 2025, driven by advancements in automation and smart technologies. AI-driven conveyor systems can optimize routing, reduce energy consumption, and minimize downtime through predictive maintenance. Such innovations not only streamline processes but also contribute to significant cost savings, making them essential for businesses aiming to stay competitive.

Tips for successful implementation of AI in conveyor systems include starting with a clear strategy that aligns AI capabilities with business goals. Regular training for staff on operating and maintaining smart conveyor systems is essential, as human proficiency directly affects the technology’s effectiveness. Furthermore, it’s crucial to invest in scalable solutions that allow for future upgrades and integrations, ensuring long-term sustainability.

As industries increasingly realize the benefits of automation, the role of AI and machine learning in conveyor technology will only grow. Recent studies indicate that automation can improve productivity by up to 30%, allowing companies to focus resources on more strategic initiatives while enabling faster and more accurate material handling operations. Embracing these technologies now will pave the way for a more efficient and innovative future.

The landscape of conveyor technology is rapidly evolving, with sustainability emerging as a central theme. Recent studies highlight that nearly 70% of industrial operations are seeking to implement eco-friendly solutions within the next decade. Innovations such as energy-efficient motors and regenerative drives are becoming standard features in modern conveyor systems. According to a report by MarketsandMarkets, the global conveyor system market is anticipated to reach $11.49 billion by 2026, driven not only by efficiency but also by the demand for systems that reduce environmental impact.

Additionally, manufacturers are exploring the use of recyclable materials and modular designs in conveyor belts, which can significantly decrease waste and enhance lifecycle management. A study by the International Energy Agency (IEA) indicates that optimizing conveyor systems could reduce energy consumption in manufacturing facilities by up to 30%. As industries strive for carbon neutrality, the integration of smart technologies and IoT is enabling real-time monitoring and performance optimization, allowing companies to minimize their carbon footprint while boosting operational efficiency. These advancements showcase a promising future, where eco-consciousness and automation go hand in hand in shaping sustainable industrial practices.

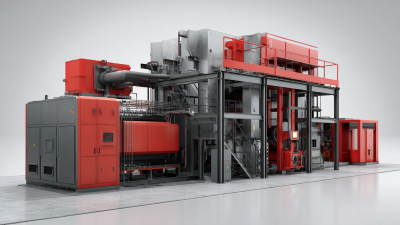

Modern conveyor technology plays a pivotal role in reshaping industries by prioritizing automation and safety. Advanced conveyor systems are designed with integrated safety features that protect workers from potential hazards associated with material handling. For instance, sensors can detect obstructions, automatically halting operations to prevent accidents, while emergency stops allow for quick intervention in critical situations. This focus on safety not only safeguards employees but also fosters a more efficient workplace environment.

Modern conveyor technology plays a pivotal role in reshaping industries by prioritizing automation and safety. Advanced conveyor systems are designed with integrated safety features that protect workers from potential hazards associated with material handling. For instance, sensors can detect obstructions, automatically halting operations to prevent accidents, while emergency stops allow for quick intervention in critical situations. This focus on safety not only safeguards employees but also fosters a more efficient workplace environment.

Furthermore, the implementation of smart conveyor systems enhances productivity in ways previously unimagined. With the advent of IoT and AI integration, conveyors can now optimize their routing and speed based on real-time data, maintaining seamless workflows across operations. These innovations enable businesses to minimize downtime and maximize throughput. By automating repetitive tasks and ensuring safety, modern conveyor technologies are transforming the workplace, allowing workers to shift their focus to more complex and value-added activities, ultimately driving innovation and growth across various sectors.