In the rapidly evolving landscape of modern manufacturing, efficiency has become the cornerstone of competitive advantage. The introduction of Heavy Roller Conveyor Assembly Lines has significantly transformed production processes, leading to notable improvements in output and productivity. According to a report by the International Society of Automation, automated conveyor systems can increase manufacturing efficiency by up to 50%, reducing labor costs and minimizing human error. Heavy Roller Conveyor Assembly Lines, specifically designed for transporting heavy loads, optimize the workflow and enhance the speed of assembly operations. A recent study by the National Institute of Standards and Technology found that implementing such systems can decrease production time by 30% while simultaneously increasing the operational capacity. As industries seek innovative ways to improve their manufacturing capabilities, the Heavy Roller Conveyor Assembly Line stands out as a critical solution in realizing enhanced efficiency and operational excellence.

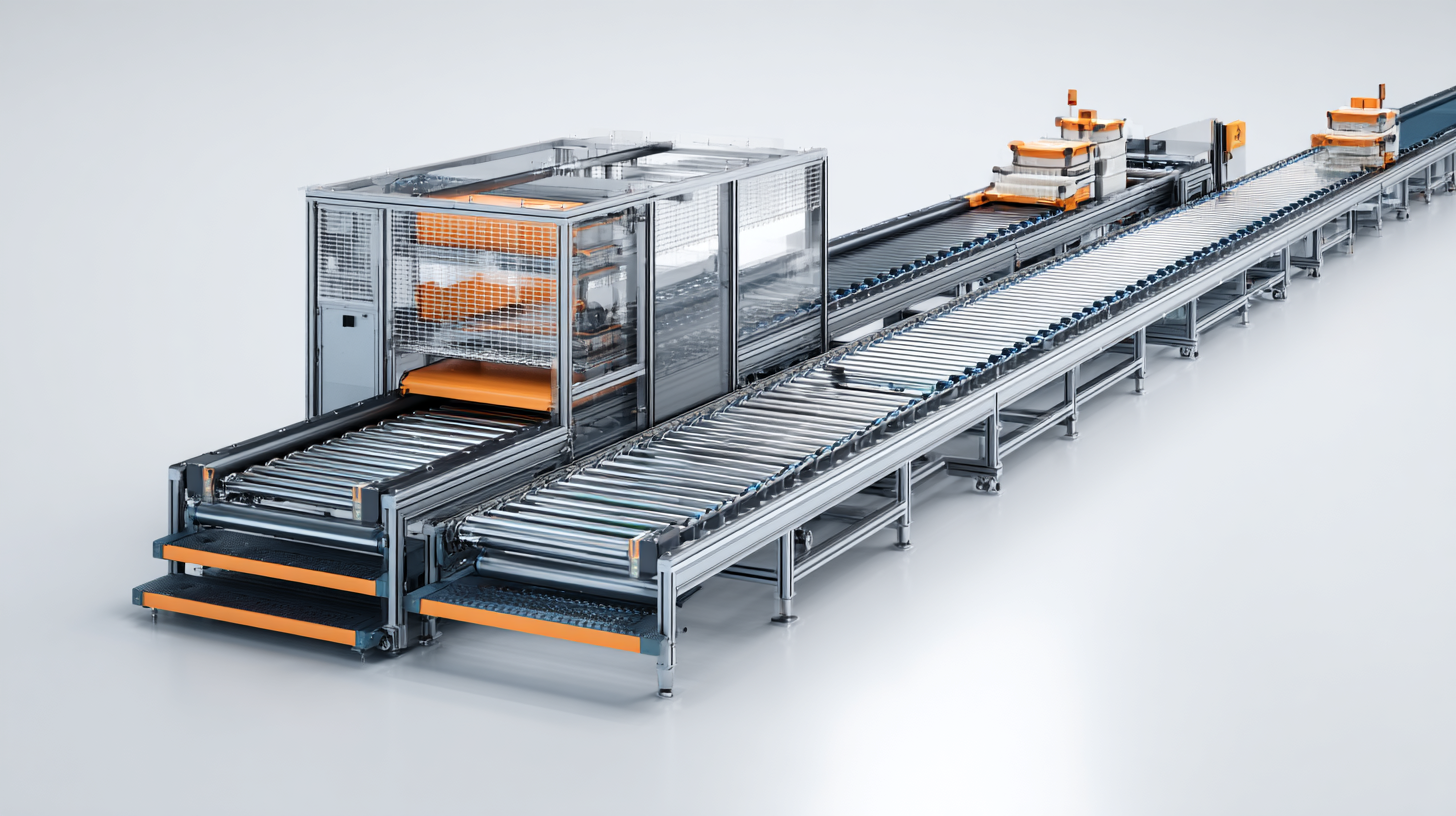

Heavy roller conveyor assembly lines are pivotal in modern manufacturing, providing a robust framework for efficient production processes. These systems utilize heavy-duty rollers to facilitate the movement of products through various stages of assembly, effectively reducing manual labor and minimizing the risk of damage to goods. By employing gravity and mechanical power, heavy roller conveyors can transport items over considerable distances with minimal energy consumption, thereby enhancing overall operational efficiency.

Heavy roller conveyor assembly lines are pivotal in modern manufacturing, providing a robust framework for efficient production processes. These systems utilize heavy-duty rollers to facilitate the movement of products through various stages of assembly, effectively reducing manual labor and minimizing the risk of damage to goods. By employing gravity and mechanical power, heavy roller conveyors can transport items over considerable distances with minimal energy consumption, thereby enhancing overall operational efficiency.

Understanding the principles behind heavy roller conveyor assembly lines is essential for manufacturers aiming to optimize their workflows. The design of these conveyors allows for seamless integration with existing production lines, providing the flexibility to adapt to different product shapes and sizes. Additionally, the smooth movement enabled by the rollers decreases wear and tear on both the products and the machinery, leading to lower maintenance costs and downtime. The ability to customize these systems according to specific manufacturing needs further underscores their critical role in streamlining operations and improving output quality.

The integration of heavy roller conveyor systems in assembly lines has revolutionized modern manufacturing, offering significant advantages that elevate productivity. According to a report by the Institute of Industrial Engineers, the implementation of conveyor systems can increase operational efficiency by up to 25%. This increase is primarily due to the ability of heavy roller conveyors to handle larger loads with reduced manual intervention, minimizing the risk of worker fatigue and errors.

Moreover, heavy roller conveyor systems enhance workflow optimization by streamlining the transportation of goods throughout the manufacturing process. Research from the Material Handling Industry of America indicates that automated conveyor systems can reduce product handling time by up to 50%. This not only accelerates production cycles but also ensures consistent product quality by reducing handling-related damages. By incorporating advanced technology and robust design, heavy roller conveyor assemblies allow manufacturers to maintain higher processing speeds while meeting increased demands for efficiency and reliability in today’s competitive landscape.

Heavy roller conveyor assembly lines are increasingly becoming a cornerstone of modern manufacturing, significantly optimizing workflow and enhancing overall productivity. According to a report by the Material Handling Industry of America, the effective implementation of conveyor systems can reduce labor costs by up to 20% while improving throughput by more than 30%. This efficiency stems from the ability of conveyor systems to move products seamlessly through various stages of production, reducing bottlenecks and ensuring a smooth transition from assembly to packaging.

To further optimize workflow in manufacturing, companies should consider integrating smart technologies within conveyor assembly lines. Data from the International Society of Automation indicates that manufacturers utilizing IoT-enabled conveyors can achieve real-time monitoring and predictive maintenance, resulting in a 10-15% increase in equipment uptime. Moreover, leveraging automated sorting mechanisms alongside heavy roller conveyors allows for a more streamlined distribution process, enhancing logistics efficiency. By adopting such technologies, businesses can not only boost production speed but also maintain higher quality standards, fostering a more agile and responsive manufacturing environment.

Effectively maintaining heavy roller conveyor systems is vital for modern manufacturing efficiency. According to a report by the Material Handling Industry of America, proper maintenance can enhance conveyor longevity by up to 30%. This underscores the importance of implementing best practices in maintaining these essential systems, which are the backbone of assembly lines and facilitate smooth operations.

One effective tip is to establish a routine inspection schedule. Regularly checking for wear and tear, loose components, and alignment issues can prevent small problems from escalating into costly downtime. Additionally, investing in a predictive maintenance program can help manufacturers anticipate potential failures based on data analytics and historical performance, leading to significant cost savings.

Remember to prioritize lubrication, as it plays a critical role in the longevity of roller bearings and motor systems. Utilizing the right type and amount of lubricant can dramatically reduce friction and wear. According to the Conveyor Equipment Manufacturers Association, proper lubrication can improve energy efficiency by 20%, making it not only a maintenance best practice but also an excellent energy-saving strategy.

The future of conveyor technology is poised for revolutionary advancements aimed at enhancing efficiency in manufacturing processes. Emerging innovations, such as the integration of smart sensors and IoT connectivity, are set to transform heavy roller conveyor assembly lines. These technologies enable real-time monitoring and data collection, allowing manufacturers to optimize operations through predictive maintenance and improved workflow management. Enhanced data analytics can identify bottlenecks and inefficiencies, leading to strategic adjustments that significantly boost productivity.

Moreover, the development of eco-friendly materials and energy-efficient designs will redefine the sustainability aspect of conveyor systems. Future conveyors are likely to incorporate modular designs that facilitate quick upgrades and customization, catering to the diverse needs of various industries. Automated systems equipped with artificial intelligence will further streamline operations, enabling faster sorting and processing capabilities. As these innovations take shape, manufacturers will not only enhance their efficiency but also adapt more swiftly to the evolving demands of the market, leading to a more resilient production environment.