Industrial conveyors play a pivotal role in enhancing supply chain efficiency and driving cost reductions across various sectors. According to a report by the International Federation of Robotics, the use of automated conveyor systems has increased productivity by up to 30% in manufacturing environments. As businesses face growing pressure to optimize operations in a competitive landscape, the integration of industrial conveyors can significantly streamline processes, reduce manual labor costs, and minimize product handling time. Furthermore, a recent study by MarketsandMarkets indicates that the global conveyor systems market is expected to reach $9.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.2%. This underscores the critical importance of adopting industrial conveyors not only for immediate operational improvements but also for long-term strategic advantages in supply chain management.

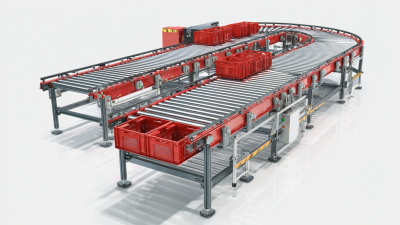

Industrial conveyors play a crucial role in streamlining supply chains by enhancing operational efficiency and reducing costs. These systems facilitate the seamless movement of goods through various stages of production and distribution, which significantly minimizes the time and labor involved in manual handling. Automation technologies integrated with conveyor systems further optimize these processes, ensuring precision and saving valuable time by automating repetitive tasks.

Industrial conveyors play a crucial role in streamlining supply chains by enhancing operational efficiency and reducing costs. These systems facilitate the seamless movement of goods through various stages of production and distribution, which significantly minimizes the time and labor involved in manual handling. Automation technologies integrated with conveyor systems further optimize these processes, ensuring precision and saving valuable time by automating repetitive tasks.

Moreover, the adoption of AI can elevate the functionality of industrial conveyors by providing real-time data analysis. This information can be harnessed to predict maintenance needs, thereby preventing breakdowns and extending equipment lifespan. Using generative AI also allows for improved procurement processes, ensuring that materials are available exactly when needed, thus reducing inventory costs.

Tips:

Innovative conveyor technologies are transforming the landscape of supply chain operations by significantly enhancing efficiency and driving cost savings. According to a recent report by Grand View Research, the global conveyor systems market was valued at approximately $7.25 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% through 2028. This growth is largely fueled by advancements in automation and smart conveyor systems that improve throughput and reliability.

Modern conveyor solutions, such as automated guided vehicles (AGVs) and modular conveyor belts, not only reduce manual labor costs but also minimize errors associated with order fulfillment. A study by McKinsey & Company highlights that optimizing logistics processes, including the implementation of these innovative conveyors, can lead to a reduction in operational costs by up to 20%. Implementing energy-efficient conveyor systems can further yield savings in energy expenses, which can account for around 30% of a facility's total operational costs.

**Tip**: To maximize the benefits of conveyor systems, consider integrating real-time monitoring technologies that enable predictive maintenance, minimizing downtime and extending the lifespan of the equipment.

In addition, businesses should evaluate the scalability of their conveyor systems. As demand fluctuates, having flexible and expandable conveyor solutions can maintain efficiency without incurring significant up-front investments. By investing in the right technologies, companies can significantly improve supply chain efficiency while achieving long-term cost reduction.

Integrating industrial conveyors into existing supply chain systems can significantly enhance both efficiency and cost-effectiveness. According to a report by the Material Handling Industry of America (MHIA), the use of conveyor systems can increase productivity by up to 25% while reducing operational costs by around 30%. This is achieved through the automation of material handling processes, which allows for faster movement of goods and minimizes the risk of human error.

To effectively integrate conveyor systems, companies should first assess their current supply chain workflows. This includes identifying bottlenecks and areas where manual processes slow down operations. By strategically placing conveyors at critical points in the supply chain, businesses can facilitate smoother transitions between production stages. The International Society of Automation (ISA) suggests that a well-designed conveyor system tailored to specific operational needs can also lead to a reduction in labor costs, as automation reduces the workforce needed for repetitive tasks. By investing in the right conveyor technology, companies can not only streamline their supply chains but also gain a competitive edge in the market.

The integration of conveyor systems within industrial settings has proven to be a pivotal factor in enhancing supply chain efficiency. By automating the movement of goods, these systems significantly reduce the time products spend in transit, allowing for faster throughput and improved responsiveness to market demands. This automation minimizes manual handling, which not only expedites processes but also reduces the likelihood of errors and workplace injuries. Consequently, organizations can achieve a more reliable operation, ultimately leading to increased customer satisfaction and loyalty.

When analyzing the return on investment (ROI) of conveyor systems, it becomes clear that the initial capital outlay is often offset by substantial long-term savings in operational costs. Conveyor systems lower labor costs by reducing the number of employees needed for manual material handling and minimize equipment wear and tear, which decreases maintenance expenses. Additionally, improved workflow leads to a reduction in inventory costs as products can move through the system more efficiently. Hence, for businesses looking to optimize their supply chains, the strategic implementation of conveyor systems represents not just an enhancement in productivity but a significant reduction in overall operational expenditures.

| Conveyor Type | Initial Investment ($) | Annual Maintenance Cost ($) | Labor Savings (% reduction) | Operational Efficiency Improvement (%) | Estimated ROI (Years) |

|---|---|---|---|---|---|

| Belt Conveyor | 50,000 | 5,000 | 20 | 15 | 4 |

| Roller Conveyor | 40,000 | 4,000 | 25 | 12 | 3.5 |

| Chain Conveyor | 70,000 | 7,000 | 30 | 20 | 3 |

| Bucket Conveyor | 60,000 | 6,000 | 18 | 16 | 4 |

| Screw Conveyor | 45,000 | 4,500 | 15 | 10 | 5 |

Maintaining industrial conveyors is crucial for optimizing supply chain efficiency and reducing costs. According to a report by the Material Handling Industry of America, improper conveyor maintenance can lead to a 20-30% decrease in productivity. Therefore, establishing a proactive maintenance schedule is essential. Regular inspections, lubrication, and timely replacements of worn-out components can significantly extend the lifespan of conveyors and reduce the likelihood of costly downtime.

**Tip:** Implement a preventive maintenance program that includes daily checks and monthly deep inspections. Utilizing condition-monitoring technologies, such as vibration analysis and thermal imaging, can further enhance the reliability of your conveyor systems.

Moreover, performance optimization of conveyors can be achieved through strategic upgrades and smart technology integration. Research from the Conveyor Equipment Manufacturers Association indicates that automating conveyor operations can improve efficiency by up to 40%. Adopting variable frequency drives (VFDs) and advanced control systems can help in adjusting conveyor speed according to real-time needs, thus enhancing energy savings and reducing wear and tear on the equipment.

**Tip:** Invest in training your maintenance team on the latest technologies and best practices in conveyor management to ensure that your systems are operating at peak performance. Regular training can empower your team to quickly identify issues and implement solutions effectively.

This chart illustrates the relationship between the maintenance frequency of industrial conveyors and the overall supply chain efficiency and cost reduction. The data shows how regular maintenance leads to improvements in operational performance.