In the rapidly evolving landscape of modern automation, understanding the critical role of Industrial Conveyor Systems is paramount for businesses aiming to enhance operational efficiency and productivity. These systems, which facilitate the seamless movement of materials within various industries, have become indispensable in manufacturing, warehousing, and distribution processes. As companies strive to integrate advanced technologies and streamline operations, Industrial Conveyor Systems not only aid in the mechanization of material handling but also contribute significantly to reducing labor costs and minimizing human error. The advent of smart technologies, such as IoT and AI, further elevates the capabilities of these conveyor systems, leading to more intelligent and responsive automation solutions. This article delves into the myriad ways Industrial Conveyor Systems are transforming workflows and establishing new benchmarks for performance in the age of automation.

The evolution of industrial conveyor systems has significantly impacted automation technology, allowing businesses to enhance efficiency and productivity. Historically, conveyor systems were manually operated and limited in scope. However, with advancements in robotics and IoT, modern conveyor systems now integrate smart technologies that enable real-time tracking and monitoring. According to a report by Allied Market Research, the global conveyor system market is projected to reach $7.2 billion by 2027, reflecting a compound annual growth rate (CAGR) of 4.9% from 2020.

These advancements have transformed how industries operate, particularly in manufacturing and logistics. Automated conveyor systems now feature sensors and AI-driven software that optimize workflow, reduce downtime, and enhance product handling. For instance, a study by McKinsey estimated that implementing automation in warehouses could reduce labor costs by up to 30%. This shift not only improves operational efficiency but also enables businesses to respond swiftly to market changes and consumer demands, underscoring the critical role of conveyor systems in the future of industrial automation.

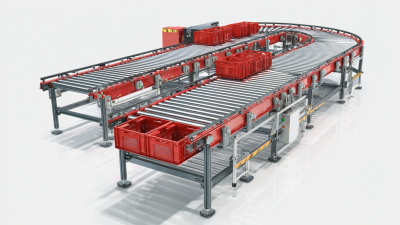

Industrial conveyor systems play a crucial role in enhancing manufacturing efficiency by streamlining production processes. These automated solutions facilitate the movement of goods through various stages of production, minimizing manual handling and reducing the chances of errors. By automating the transportation of materials, manufacturers can significantly decrease cycle times and increase throughput, enabling them to meet the growing demands of the market.

Industrial conveyor systems play a crucial role in enhancing manufacturing efficiency by streamlining production processes. These automated solutions facilitate the movement of goods through various stages of production, minimizing manual handling and reducing the chances of errors. By automating the transportation of materials, manufacturers can significantly decrease cycle times and increase throughput, enabling them to meet the growing demands of the market.

Another key benefit of implementing conveyor systems is the optimization of workflow and resource utilization. With features such as modular design and customizable configurations, these systems can be tailored to specific operational needs, allowing for smooth integration into existing processes. Additionally, conveyor systems enhance workplace safety by reducing the risks associated with lifting heavy loads and navigating through busy environments. Overall, incorporating these systems not only boosts productivity but also fosters a safer and more efficient manufacturing environment.

In the rapidly evolving landscape of modern manufacturing, the integration of conveyor systems into supply chains has proven to be a pivotal factor in optimizing operational efficiency. According to a report by the Material Handling Industry (MHI), companies that adopt advanced conveyor solutions see a potential reduction in labor costs by up to 20%, significantly enhancing productivity. This statistic underscores the transformative role that automated conveyor systems play, facilitating the swift movement of goods while minimizing human error.

Moreover, the seamless integration of conveyor systems can lead to better inventory management and reduced lead times. A study by the Institute of Supply Chain Management (ISCM) reveals that businesses utilizing advanced conveyor technologies experience a reduction in order fulfillment times by as much as 30%. Such improvements not only boost customer satisfaction through timely deliveries but also create a more agile supply chain capable of responding to market fluctuations. As industries continue to embrace automation, the significance of conveyor systems cannot be overstated, highlighting their crucial role in enhancing supply chain performance.

In today's rapidly evolving industrial landscape, the integration of conveyor systems with automation and robotics is more crucial than ever. According to a recent report by MarketsandMarkets, the global conveyor system market is projected to reach $8.2 billion by 2025, growing at a CAGR of 4.7%. This growth underscores the increasing reliance on conveyor technologies to enhance operational efficiency and throughput.

Current trends indicate a growing collaboration between conveyor systems and advanced robotics, which can lead to more streamlined processes. For instance, the introduction of autonomous mobile robots (AMRs) has revolutionized material handling, allowing for seamless transportation of goods along conveyor belts. The Association for Advancing Automation (A3) highlights that companies employing robotic solutions alongside conveyor systems have reported up to a 30% increase in productivity. Additionally, integrating IoT technologies into conveyor systems is facilitating real-time monitoring and predictive maintenance, optimizing both performance and lifespan.

This transformative synergy is not only enhancing efficiency but also enabling manufacturers to meet the rising demands of customization and speed. As industries continue to embrace automation, the collaboration between conveyor systems and robotics will play a pivotal role in shaping the future of manufacturing and logistics.

The landscape of industrial automation is poised for transformation, particularly through innovations in conveyor technologies. As manufacturers strive for enhanced productivity, advancements such as smart conveyor systems equipped with IoT sensors are at the forefront. These systems facilitate real-time data analysis, allowing for predictive maintenance and minimizing downtime. By automating monitoring processes, companies can ensure smoother operations and optimal performance directly translating into increased output.

Moreover, advances in materials science are leading to lighter, more durable conveyor belts that can handle a wider range of products. For instance, the integration of AI algorithms enables these systems to adapt to varying load conditions and speeds dynamically. Innovations like modular conveyor designs are also emerging, providing flexibility in production lines and enabling easy scalability to meet demand fluctuations. As these technologies evolve, they promise to redefine efficiency standards in manufacturing, ensuring that businesses can respond swiftly to market changes while maintaining high operational effectiveness.