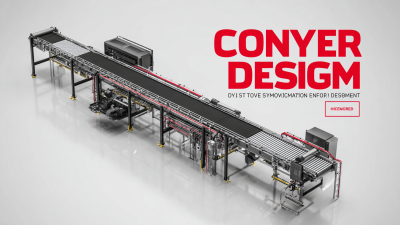

As the global manufacturing landscape evolves, innovative Conveyor System Design is becoming a centerpiece for enhancing efficiency and productivity. The upcoming 2025 China Import and Export Fair (the 138th Canton Fair) will showcase the latest trends in conveyor technology, reflecting a projected growth of over 6% in the conveyor system market over the next five years, as reported by industry experts. This growth is driven by the increasing demand for automation and streamlined logistics in manufacturing processes. Advanced conveyor systems are not only optimizing operations but also integrating smart technologies that facilitate real-time monitoring and data analysis. With China's ambition to lead in manufacturing innovation, the 2025 Fair promises to unveil cutting-edge solutions that will redefine Conveyor System Design, positioning manufacturers for success in an increasingly competitive global marketplace.

The 2025 China Import and Export Fair is set to showcase transformative innovations in conveyor system design, driven by emerging technologies that promise to enhance efficiency in manufacturing. As industries increasingly seek automation and optimization, cutting-edge materials and intelligent systems will take center stage. For instance, the integration of AI and machine learning enables predictive maintenance, which minimizes downtime and improves productivity across the supply chain.

Additionally, advancements in sensor technologies are reshaping how conveyor systems operate. Smart sensors can monitor product movements and detect potential issues in real-time, allowing for seamless operations and enhanced safety. Furthermore, the introduction of modular conveyor systems is providing manufacturers with flexibility and scalability, adapting to varying production demands with ease. As these technologies converge, the conveyor systems of tomorrow will not only streamline processes but also contribute to a more sustainable manufacturing ecosystem.

| Trend | Description | Impact on Manufacturing | Implementation Year |

|---|---|---|---|

| Automation Integration | Incorporating AI and machine learning to improve efficiency. | Increases throughput and reduces manual labor costs. | 2025 |

| Sustainability Focus | Designing systems that minimize energy consumption and waste. | Promotes eco-friendly practices and reduces costs. | 2025 |

| Modular Designs | Flexible systems that can be easily modified or expanded. | Enhances adaptability to changing production needs. | 2025 |

| Smart Sensors | Using IoT sensors for real-time monitoring and data collection. | Facilitates predictive maintenance and reduces downtime. | 2025 |

| Advanced Materials | Implementing lightweight and durable materials in conveyor design. | Increases load capacity and extends lifespan of the systems. | 2025 |

The manufacturing industry is undergoing a significant transformation, particularly in the design and functionality of conveyor systems. As highlighted in the 2025 China Import and Export Fair, sustainability is not just a trend but a necessity for modern manufacturing practices. Industry reports indicate that over 65% of manufacturing companies are now prioritizing environmentally friendly solutions, with conveyor system designs shifting toward materials that are recyclable and energy-efficient. This transition is essential in reducing the carbon footprint associated with traditional manufacturing processes.

Incorporating sustainability into conveyor systems also focuses on reducing waste and energy consumption. A recent study by the International Journal of Advanced Manufacturing Technology found that innovative conveyor designs can lead to a 30% reduction in energy usage compared to conventional systems. These advancements include the use of smart technology for monitoring and optimizing energy consumption, as well as enhanced materials that use less energy in their production processes. Manufacturers are increasingly adopting these sustainable practices, not only to comply with regulatory standards but also to meet the growing consumer demand for greener products.

The integration of smart automation in conveyor system solutions is a pivotal trend shaping the future of manufacturing, particularly as the industry prepares for the 2025 China Import and Export Fair. The closed belt conveyor market is set to experience significant growth, with an estimated market size of $306.8 million in 2024, projected to reach $312.95 million by 2025, and potentially growing to $366.62 million by 2033. This upward trajectory reflects an increasing demand for more efficient and automated material handling solutions in diverse manufacturing sectors.

Companies are actively pursuing strategies to enhance their smart automation capabilities, ensuring they remain competitive in a rapidly evolving market. Recent developments, such as strategic acquisitions and IPOs in the materials handling sector, highlight a robust movement towards innovation and technological advancement. For instance, a notable acquisition not only garnered market attention but also strengthened the acquiring company's position in intelligent manufacturing, showcasing how integration of automated solutions is vital for future growth and success in the conveyor system landscape.

The evolution of conveyor systems is increasingly characterized by customization and modularity, two trends that are reshaping manufacturing processes. As industries aim for greater efficiency and flexibility, the ability to tailor conveyor systems to specific operational needs has become paramount. A report by the Material Handling Industry of America states that customized conveyor systems can enhance productivity by up to 30%, allowing manufacturers to adapt their lines quickly in response to changing demands. By integrating modular components, businesses can expand and reconfigure their systems without extensive downtime or overhaul, a key factor in maintaining competitive advantage in a fast-paced market.

Furthermore, the implementation of modular design in conveyor systems not only reduces installation time but also lowers costs. According to a study conducted by MarketsandMarkets, the global market for modular conveyor systems is projected to grow from $3.5 billion in 2021 to $5.3 billion by 2026, driven by the demand for flexible and scalable solutions. This trend aligns with the increasing adoption of advanced manufacturing technologies, such as Industry 4.0, where smart production and real-time monitoring necessitate highly adaptable systems. As we approach the 2025 China Import and Export Fair, it's clear that these design trends are not just innovations but essential strategies for optimizing manufacturing operations in the modern economy.

As manufacturing continues to evolve, the integration of data analytics into conveyor systems is set to revolutionize efficiency. According to a recent report by the International Society for Automation, companies that leverage advanced data analytics solutions can enhance operational efficiency by up to 20%. By collecting and analyzing data from various points along the conveyor system, manufacturers can identify bottlenecks, predict maintenance needs, and optimize workflow, resulting in significant cost savings and productivity gains.

Tips: To maximize the benefits of data analytics in your conveyor design, invest in IoT sensors that can gather real-time data. Implementing a robust analytics platform can also facilitate better decision-making by offering insights that were previously inaccessible. Collaborating with data scientists can help you interpret this data effectively.

The future of conveyor systems is bright, especially with the ongoing advancements in AI and machine learning. These technologies enable predictive analytics, which allows manufacturers to foresee equipment failures before they occur, minimizing downtime. A study from Deloitte highlighted that predictive maintenance can reduce equipment failure costs by as much as 30%. By embracing these innovations, manufacturers can not only improve conveyor efficiency but also stay competitive in the fast-paced market of the future.

Tips: Regularly review and update your data collection strategies to ensure you are capturing the most relevant metrics, and consider cross-training your staff on both engineering and data analytics to foster a culture of continuous improvement.