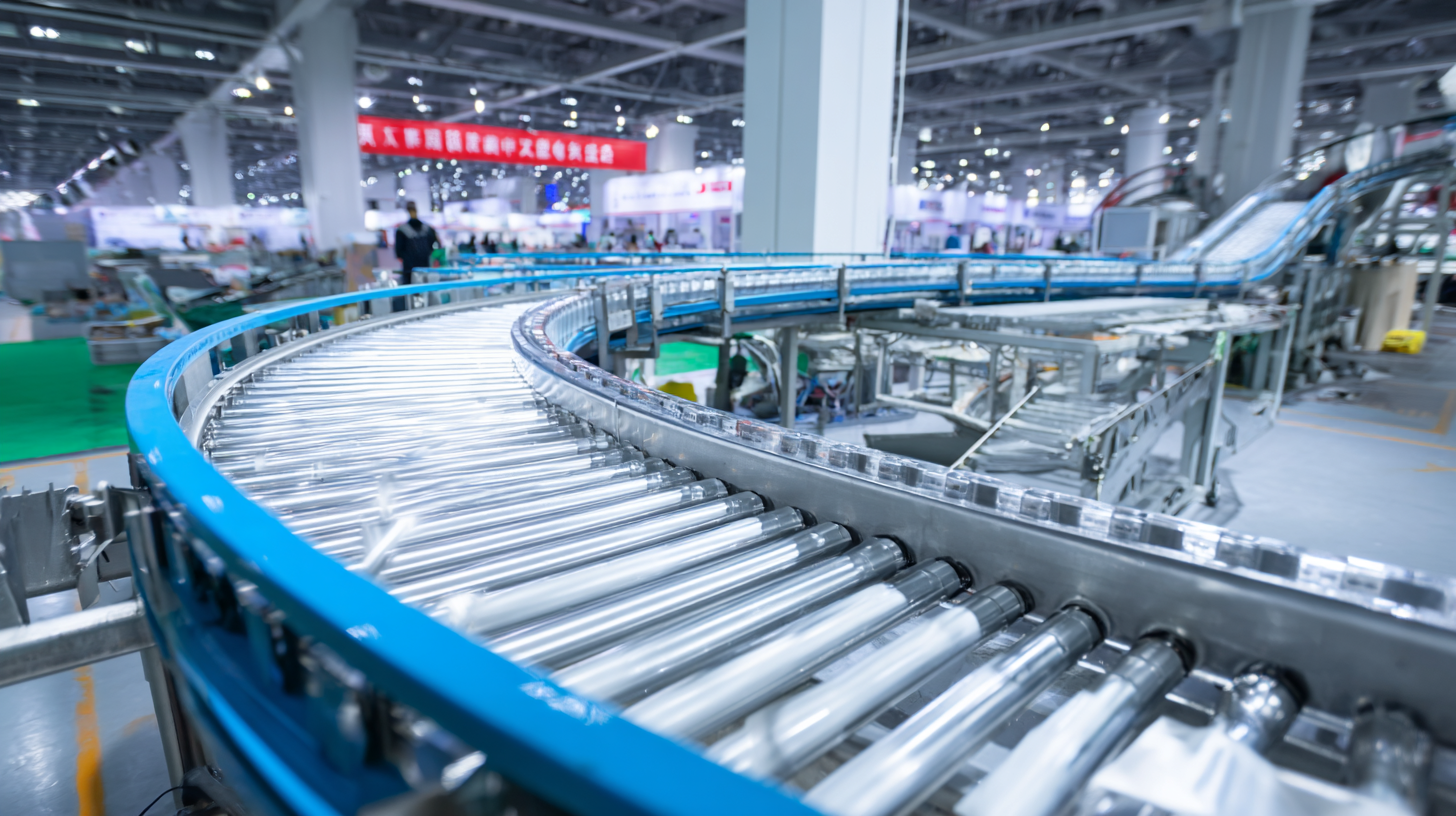

The rapid evolution of technology has significantly influenced various industries, with conveyor system design emerging as a focal point in enhancing operational efficiency and productivity. At the 2025 China Import and Export Fair, specifically the 138th session, innovative conveyor system design trends will take center stage, showcasing cutting-edge solutions that cater to the evolving demands of logistics and supply chain management.

As manufacturers and suppliers gather to display their latest advancements, attendees will witness how modern conveyor systems integrate smart technologies, ergonomic considerations, and sustainable practices to streamline processes. This fair serves as a crucial platform for industry professionals to explore the latest developments in conveyor system design and to engage in discussions on future innovations that will continue to shape the landscape of material handling and production facilities in the years to come.

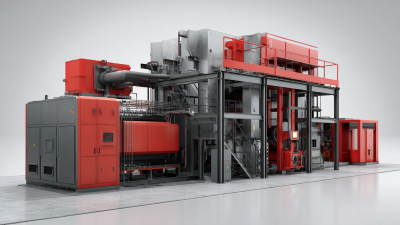

At the 2025 China Import and Export Fair, the spotlight was on emerging technologies revolutionizing conveyor systems. Exhibitors showcased advanced automation features that enhance efficiency and accuracy in material handling. Innovations such as AI-driven sorting systems and IoT-connected conveyors promise to streamline operations and reduce labor costs, allowing businesses to respond more rapidly to market demands.

In addition to automation, sustainability emerged as a critical theme. Many vendors highlighted eco-friendly materials and energy-efficient designs that minimize environmental impact. The integration of renewable energy sources and smart monitoring systems further underscores the trend towards greener manufacturing practices. This convergence of technology and sustainability is set to transform conveyor systems, making them more adaptive and environmentally responsible in the ever-evolving landscape of global trade.

At the 2025 China Import and Export Fair, the spotlight on sustainability in conveyor system design trends reflects a broader industry shift towards eco-conscious innovations. This evolution is driven by a growing awareness of environmental impacts and the need for energy-efficient solutions. The latest advancements in conveyor technology are expected to incorporate sustainable materials and energy-efficient designs, aligning with global efforts to reduce waste and carbon footprints.

The fair will showcase conveyor systems that utilize advanced automation and smart technologies, enhancing operational efficiency while minimizing resource consumption. As manufacturers embrace sustainable practices, innovative designs are prioritizing not only functionality but also recyclability and environmental responsibility. This convergence of sustainability with cutting-edge technology promises to redefine conveyor systems, making them key players in the future of manufacturing and logistics.

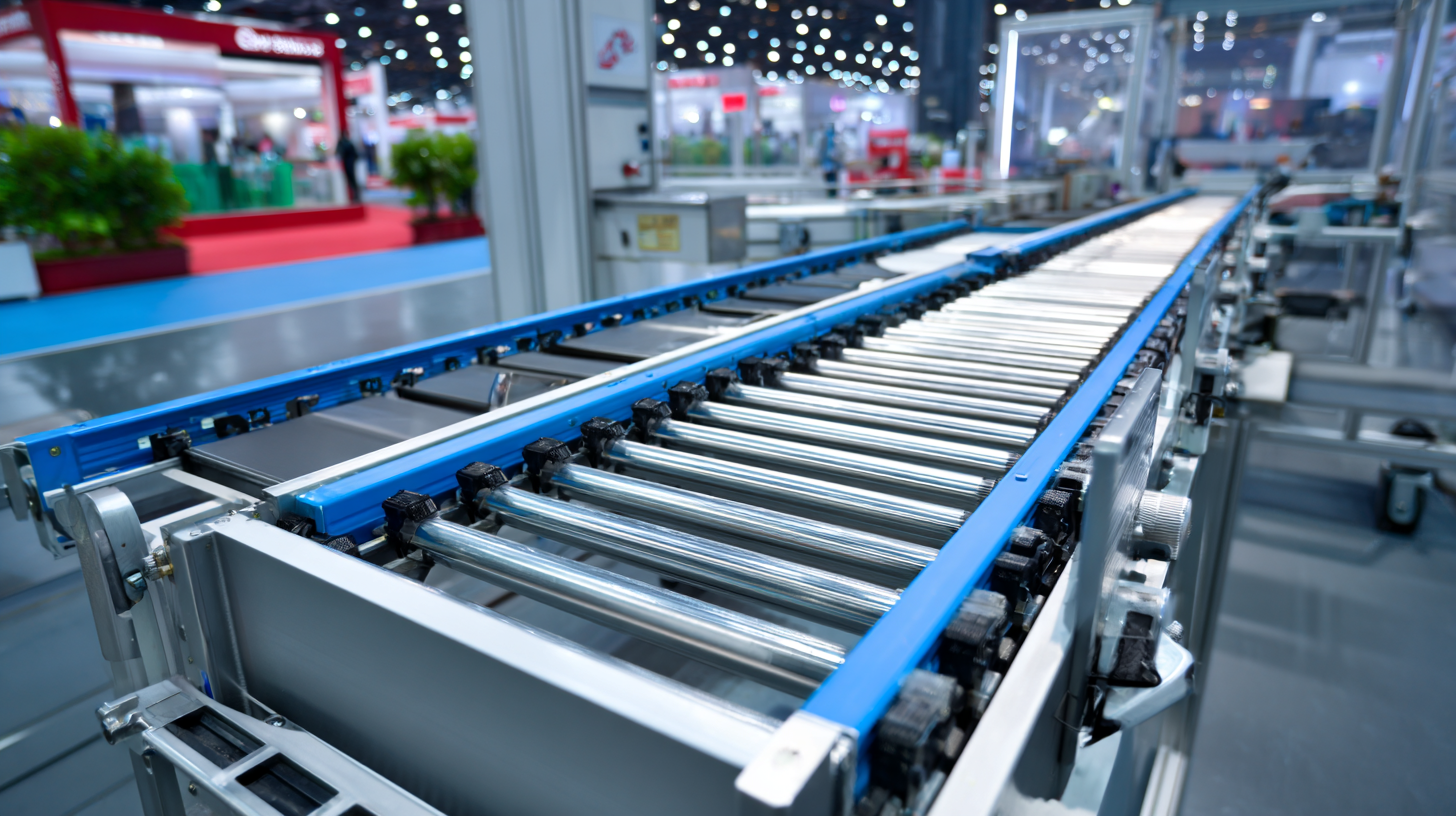

The integration of automation and AI into modern conveyor systems is reshaping the logistics and manufacturing sectors, presenting significant enhancements in operational efficiency. According to a report by Allied Market Research, the global conveyor systems market was valued at approximately $7.9 billion in 2020 and is projected to reach $11.2 billion by 2027, growing at a CAGR of 5.4%. This growth is largely driven by the increasing adoption of automated conveyor solutions that streamline processes, reduce labor costs, and improve safety standards in various industrial settings.

At the 2025 China Import and Export Fair, industry leaders are expected to showcase cutting-edge conveyor designs that leverage AI technologies for real-time monitoring and predictive maintenance. For instance, systems equipped with AI algorithms can analyze data from sensors placed along the conveyor belt to anticipate equipment failures, thereby minimizing downtime.

A study conducted by McKinsey noted that organizations implementing advanced robotics and automation experienced efficiency gains of up to 30%. As these innovations continue to evolve, the conveyor systems of the future will not only optimize material handling but also facilitate smarter warehouse management through seamless integration with other automated systems.

The 2025 China Import and Export Fair prominently showcased innovative conveyor system designs, highlighting their transformative impact across various industries. Notably, the logistics sector has seen a significant uptick in efficiency, with recent reports indicating that advanced conveyor systems can improve throughput by up to 30%. For instance, a case study involving a major e-commerce company revealed that implementing modular conveyor designs reduced package handling time by 25%, allowing for faster order fulfillment and a better customer experience.

Additionally, the manufacturing industry has benefited from the integration of smart conveyor technologies. A leading automotive manufacturer adopted a robotic conveyor system that not only streamlined assembly line processes but also reduced labor costs by approximately 15%. Data from industry reports suggest that automation in conveyor systems is projected to drive a 20% reduction in overall production time by 2026. Such successful implementations illustrate how innovative conveyor designs are not merely trends but represent a crucial evolution in operational efficiency and productivity across multiple sectors.

| Industry | Innovative Design Type | Implementation Location | Benefits Achieved | Efficiency Increase (%) |

|---|---|---|---|---|

| Food Processing | Modular Conveyor System | Factory A, Guangdong | Reduced downtime, improved hygiene | 25% |

| Automotive | Automated Guided Vehicle (AGV) Conveyor | Plant B, Shanghai | Increased throughput, reduced labor costs | 40% |

| Pharmaceuticals | Smart Conveyor System | Facility C, Beijing | Enhanced tracking and traceability | 30% |

| Packaging | Eco-friendly Conveyor Materials | Warehouse D, Jiangsu | Sustainability, reduced waste | 20% |

| E-commerce | Integrated Sorting Conveyor System | Distribution Center E, Shenzhen | Faster order fulfillment, improved accuracy | 35% |

At the 2025 China Import and Export Fair, industry leaders shared compelling insights into the future of conveyor systems, spotlighting emerging trends that promise to reshape logistics and supply chain operations. According to a recent report by the Global Conveyor Systems Market Analysis, the sector is expected to grow at a compound annual growth rate (CAGR) of 4.5% through 2030, driven by advancements in automation and Industry 4.0 technologies. This growth is propelled by the increasing demand for efficient material handling solutions across various industries, including e-commerce, manufacturing, and food processing.

During the fair, experts emphasized the integration of smart technologies in conveyor system designs, such as IoT-enabled sensors and real-time monitoring systems. This allows for enhanced operational efficiency and predictive maintenance, reducing downtime by up to 30%, as highlighted in a study by the International Material Handling Research Association. Furthermore, sustainability trends were also a focal point, with a push towards eco-friendly materials and energy-efficient systems, reflecting a broader commitment to reducing carbon footprints in industrial operations.

The innovations showcased at the fair not only illustrate the dynamic nature of the conveyor systems market but also underscore the essential role these technologies play in the future of global trade and logistics.