In today’s fast-paced industrial environment, Conveyor Technology plays a vital role. Companies strive for efficiency and productivity. A well-optimized conveyor system can cut costs and save time significantly. However, achieving maximum efficiency is not a straightforward task.

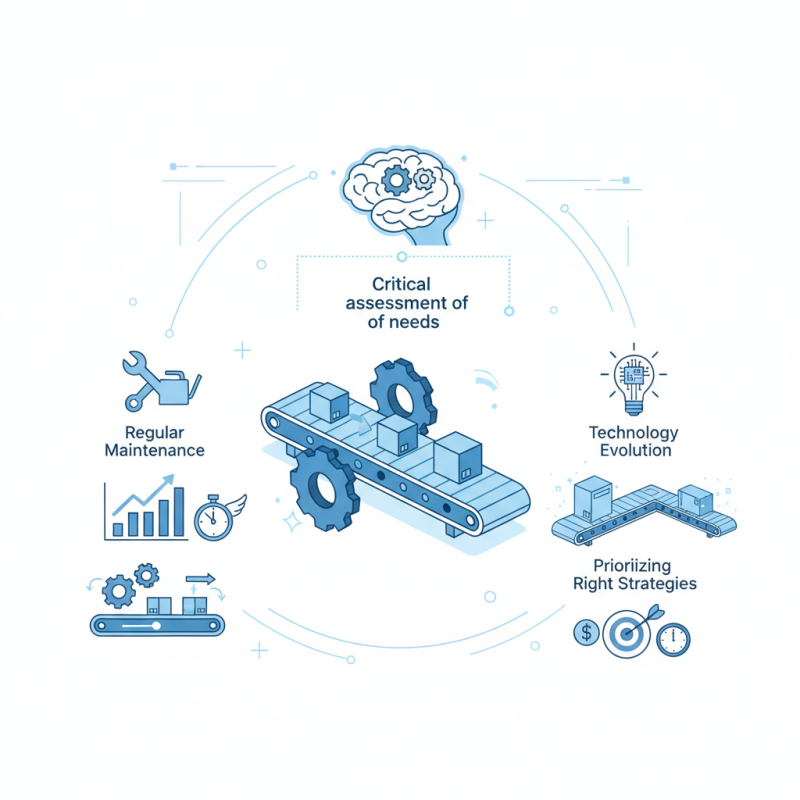

Many businesses overlook key elements that can enhance their conveyor systems. Regular maintenance, for instance, often gets neglected. This can lead to unexpected downtime. Operators may also fail to adjust speed settings for different loads, impacting workflow. It's essential to reflect on these aspects regularly. Sometimes, minor tweaks can yield significant improvements.

Additionally, technology is continuously evolving. Innovations in conveyor technology can introduce smarter solutions. Yet, not every new tool suits every operation. A critical assessment of needs is crucial. Failing to adapt can result in wasted resources. Prioritizing the right strategies can redefine efficiency in your operations.

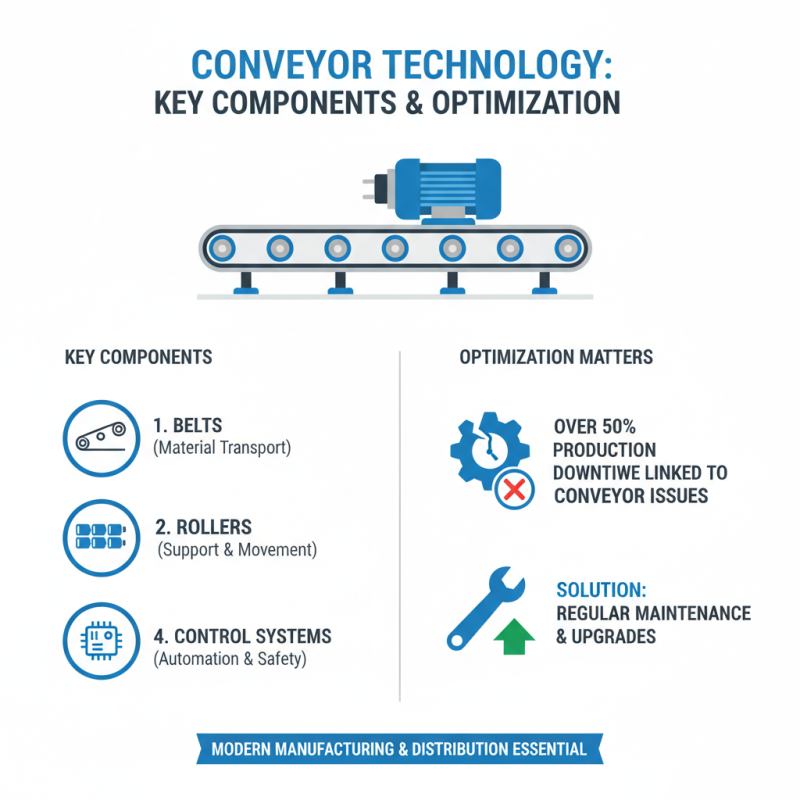

Conveyor technology plays a crucial role in modern manufacturing and distribution. Understanding its key components is essential for optimizing performance. Key parts include belts, rollers, motors, and control systems. According to industry reports, over 50% of production downtime is linked to conveyor issues. This highlights the need for regular maintenance and upgrades.

Belt selection is vital. Material choice can impact speed and durability. Experts suggest that using the right belt can improve efficiency by up to 20%. Additionally, control systems must be responsive and adaptable. Automation in conveyors can reduce human error and increase throughput. Yet, not all systems are user-friendly. Operators may struggle with complex interfaces, leading to lost time.

In terms of monitoring, sensors are underutilized. Many plants fail to implement real-time data tracking for conveyor performance. This oversight can lead to unplanned downtimes. A study found that predictive maintenance could cut operational costs by 12%. Companies often overlook these innovations, missing opportunities for improvement. Addressing these gaps is crucial for maximizing conveyor efficiency.

In today's manufacturing landscape, optimizing conveyor efficiency is crucial. Evaluating key metrics like speed, load capacity, and energy consumption can lead to significant improvements. According to a recent study by the Conveyor Equipment Manufacturers Association, enhancing conveyor system speed by just 10% can yield a 15% increase in overall productivity. Faster conveyor belts enable quicker product transportation, reducing downtime.

Load management is another essential factor. Overloading a conveyor system often results in unnecessary wear and tear. An industry report shows that operating at optimal load levels can decrease energy use by up to 30%. Companies may find that keeping loads within recommended limits not only extends equipment life but also improves reliability.

Energy consumption metrics are frequently overlooked. Research indicates that conveyor systems can consume up to 30% of a facility's energy. Implementing energy-efficient motors and variable speed drives can cut this consumption significantly. Many plants still operate outdated systems. This reflects a need for reassessment. Regular analysis of energy use helps identify areas for improvement.

Innovative materials and designs play a crucial role in optimizing conveyor technology. When selecting materials, choose those that enhance durability. For instance, lightweight composites can significantly reduce wear and tear. Incorporating high-strength polymers can also improve resistance to chemical spills. These choices lead to longer-lasting systems, which decreases downtime.

**Tip:** Regularly assess the material performance. Look for signs of degradation or fatigue. Small cracks can indicate a need for replacement. It's better to address issues early than to face costly failures later.

Design matters too. Modular conveyor systems allow for easier upgrades and repairs. This flexibility is key in dynamic industries. Adopting designs that allow quick adjustments helps maintain efficiency.

**Tip:** Keep your design adaptable. Monitor shifts in production needs. Don’t overlook feedback from operators; their insights can identify hidden inefficiencies. Embrace a culture of ongoing improvement to stay competitive.

| Dimension | Description | Material Type | Performance Rating | Expected Lifespan (Years) |

|---|---|---|---|---|

| Belt Width | Width of the conveyor belt used for material transport | TPE (Thermoplastic Elastomer) | High | 8 |

| Belt Speed | Speed at which the belt operates, affecting throughput | PU (Polyurethane) | Medium | 5 |

| Load Capacity | Maximum weight the conveyor can carry | Steel Reinforced | High | 10 |

| Durability Rating | Resistance to wear and tear under operational conditions | Nylon | Very High | 12 |

| Maintenance Frequency | How often the conveyor requires maintenance | Aluminum | Medium | Varies |

Automation and smart technologies are transforming conveyor systems. These advancements lead to significant improvements in efficiency. A study by the Material Handling Industry found that automation can boost operational efficiency by up to 30%. This shift allows manufacturers to optimize workflows and reduce bottlenecks.

Smart conveyor systems utilize sensors and AI to monitor performance in real time. An integrated approach can result in fewer breakdowns. According to a report by the International Federation of Robotics, automated solutions can reduce maintenance costs by 20%. The data highlights the importance of predictive analytics. Yet, many companies still struggle with integration challenges.

Implementing advanced technologies demands an initial investment. Some facilities may resist change due to costs. Acknowledging potential disruptions is crucial. Workforce training is often overlooked, but it’s essential for achieving optimal performance. Continuous evaluation and adaptation of technology remain necessary as industries evolve.

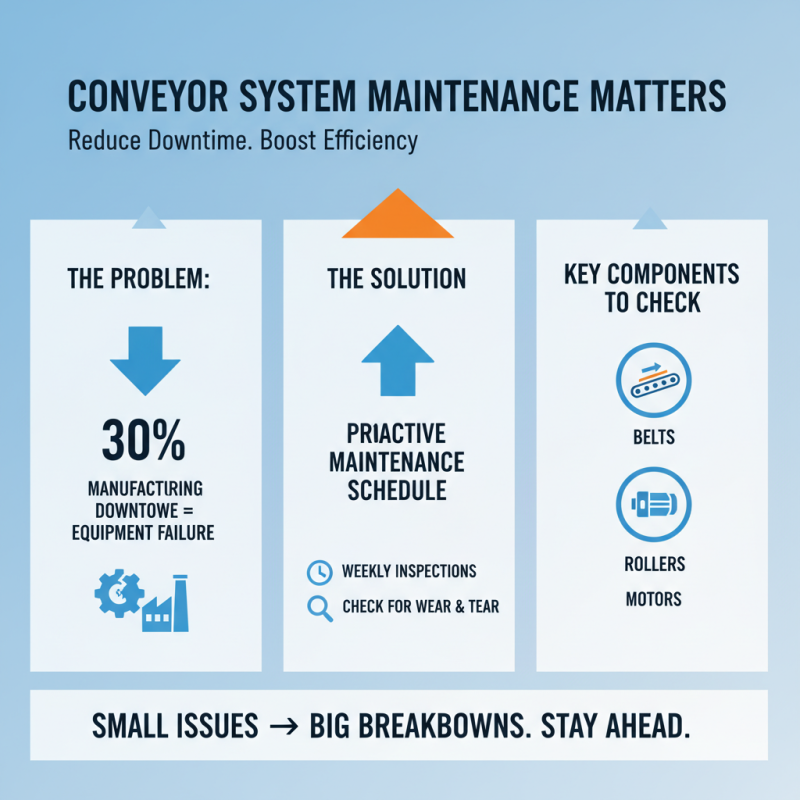

Regular maintenance is crucial for conveyor systems. According to industry reports, nearly 30% of downtime in manufacturing comes from equipment failure. A proactive maintenance schedule can reduce this significantly. Inspections should occur weekly, checking for wear and tear. Key areas to focus on include belts, rollers, and motors. Small issues can lead to significant breakdowns if neglected.

Monitoring practices enhance performance. Using sensors can provide real-time data. This data helps detect problems early. Studies indicate that predictive maintenance can lower maintenance costs by up to 25%. However, missed opportunities for data analysis are common. Many facilities overlook the importance of data in their decision-making.

It’s essential to train staff regularly. Well-informed employees recognize potential issues. Continuous education reduces mistakes and enhances efficiency. However, even the best training may not catch everything. There is always room for improvement. Regular feedback loops can help refine processes, making operations smoother.