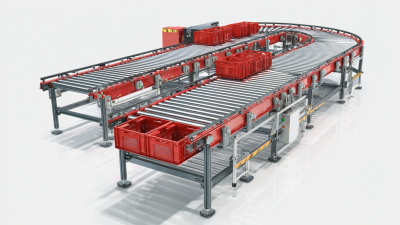

In today’s fast-paced industrial landscape, the optimization of operational efficiency is paramount, and one of the most effective ways to achieve this is through the implementation of a well-designed conveyor system. A designed conveyor not only streamlines the workflow but also minimizes manual handling, reduces production time, and enhances overall productivity.

In this ultimate guide, we will delve into the essential components that contribute to an efficient designed conveyor system, exploring the latest technology and best practices that can be employed. By understanding how to tailor a conveyor system to meet specific operational needs, businesses can significantly boost efficiency while also ensuring safety and reliability.

Join us as we navigate the intricacies of designing a conveyor system that not only meets but exceeds performance expectations, paving the way for operational excellence.

In today's fast-paced manufacturing landscape, conveyor systems play a pivotal role in enhancing efficiency and productivity. According to a report by the Material Handling Industry of America (MHIA), implementing a well-designed conveyor system can improve operational efficiency by up to 30%. This significant statistic highlights the importance of integrating advanced conveyor solutions tailored to specific manufacturing needs. As industries continuously evolve, the demand for streamlined processes has never been greater, making it essential for manufacturers to invest in reliable conveyor systems that not only minimize downtime but also maximize throughput.

Moreover, a study conducted by the Association for Manufacturing Technology (AMT) indicates that modern conveyor systems can reduce labor costs by up to 20% by automating repetitive tasks. This reduction not only alleviates the burden on workers but also allows them to focus on more value-added activities, fostering a more innovative and skilled workforce.

As the industry shifts towards greater automation, the role of conveyor systems becomes even more crucial in ensuring that operations remain agile and competitive. By understanding and prioritizing the implementation of optimized conveyor systems, manufacturers can secure their position in an increasingly dynamic market.

To ensure the highest efficiency in industrial settings, it is essential to monitor key metrics that directly assess the performance of designed conveyor systems. According to a recent report by the Material Handling Industry of America (MHIA), optimizing conveyor efficiency can increase productivity by up to 30%. Two vital metrics to consider are throughput and downtime.

In today’s competitive landscape, enhancing the efficiency of conveyor systems has become paramount, particularly through the integration of advanced automation technologies. Recent innovations in conveyor belt technology have demonstrated significant potential to elevate operational effectiveness across various industries. For instance, the global conveyor belt market is projected to grow from USD 1.5 billion in 2024 to USD 2.8 billion by 2033, reflecting a robust interest in automated solutions that streamline processes.

With the advent of artificial intelligence and machine learning, automation has introduced transformative capabilities in conveyor system design and operation. For example, an advanced conveyor belt monitoring system utilizing laser scanning and deep learning has shown promise in improving safety by detecting real-time defects, thereby minimizing downtime. Similarly, the mining sector anticipates that automated trucks will boost ore extraction efficiency by up to 30% by 2025, showcasing the tangible benefits of integrating automation. As industries continue to adopt these technologies, it is clear that strategic automation will play a crucial role in maximizing the efficacy of conveyor systems.

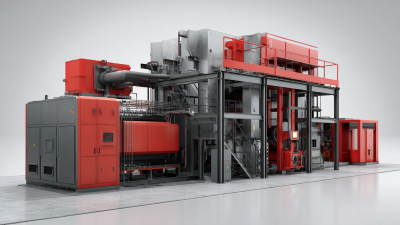

Choosing the right conveyor design is crucial for optimizing efficiency in material flow and maximizing productivity within supply chains. Factors such as belt type, speed, and layout can greatly influence not only the movement of materials but also the overall operational costs.

According to a recent report by the Association for Manufacturing Technology, companies that invest in advanced conveyor systems can improve their material handling efficiency by up to 30%. This increase directly correlates with enhanced production rates and reduced delays.

In addition, ergonomic considerations should not be overlooked when designing a conveyor system. A well-designed conveyor can minimize worker fatigue and streamline the workflow, leading to a productivity increase of around 20%. Research from the Material Handling Industry shows that businesses focusing on smart conveyor designs see a reduction in waste and product damage, further optimizing the supply chain from raw materials to the end consumer. By prioritizing the right conveyor design, organizations can significantly impact their operational efficiency and cost management in an increasingly competitive landscape.

Maintenance plays a crucial role in sustaining the efficiency of a designed conveyor system over time. Regular inspections and proactive repairs can prevent minor issues from escalating into significant problems. One of the best practices is to establish a maintenance schedule that aligns with the operational demands of your facility. Routine checks on critical components such as belts, rollers, and motors can help identify wear and tear, ensuring timely interventions.

Maintenance plays a crucial role in sustaining the efficiency of a designed conveyor system over time. Regular inspections and proactive repairs can prevent minor issues from escalating into significant problems. One of the best practices is to establish a maintenance schedule that aligns with the operational demands of your facility. Routine checks on critical components such as belts, rollers, and motors can help identify wear and tear, ensuring timely interventions.

Furthermore, keeping the conveyor system clean is essential for optimal performance. Dust and debris can cause friction and lead to breakdowns. Implementing a cleaning protocol, possibly on a weekly basis, ensures that your conveyor runs smoothly. Another tip is to train operators in basic maintenance tasks. Equipping team members with the knowledge to identify issues early can save time and costs associated with repairs.

Remember to document all maintenance activities as this provides valuable insights into the system's performance and longevity. Analyzing these records can help you adjust maintenance strategies as needed, ultimately enhancing the efficiency of your conveyor system.