In the ever-evolving landscape of industrial automation, the significance of a reliable Conveyor Machine cannot be overstated. According to a recent report by MarketsandMarkets, the global conveyor systems market is projected to reach $7.8 billion by 2025, reflecting a CAGR of 4.7%. This growth underscores the increasing reliance on conveyor systems across various sectors, including manufacturing, food processing, and logistics. The importance of selecting the right Conveyor Machine is further amplified by the diverse applications and technical specifications that vary significantly between models.

In this blog, we delve into key comparative insights and technical details that will empower you to make informed decisions when investing in conveyor technology. By unlocking the secrets behind the best Conveyor Machines, we aim to enhance operational efficiency and productivity for businesses looking to thrive in a competitive environment.

The conveyor technology landscape is set for a transformative leap towards 2025, driven by key innovations that enhance efficiency, safety, and sustainability in material handling operations. According to a report by MarketsandMarkets, the global conveyor systems market is projected to grow from $7.37 billion in 2020 to $9.60 billion by 2025, reflecting a CAGR of 5.4%. This growth is fueled by advancements such as AI integration, IoT connectivity, and energy-efficient designs that are reshaping traditional conveyor systems into smart, automated solutions.

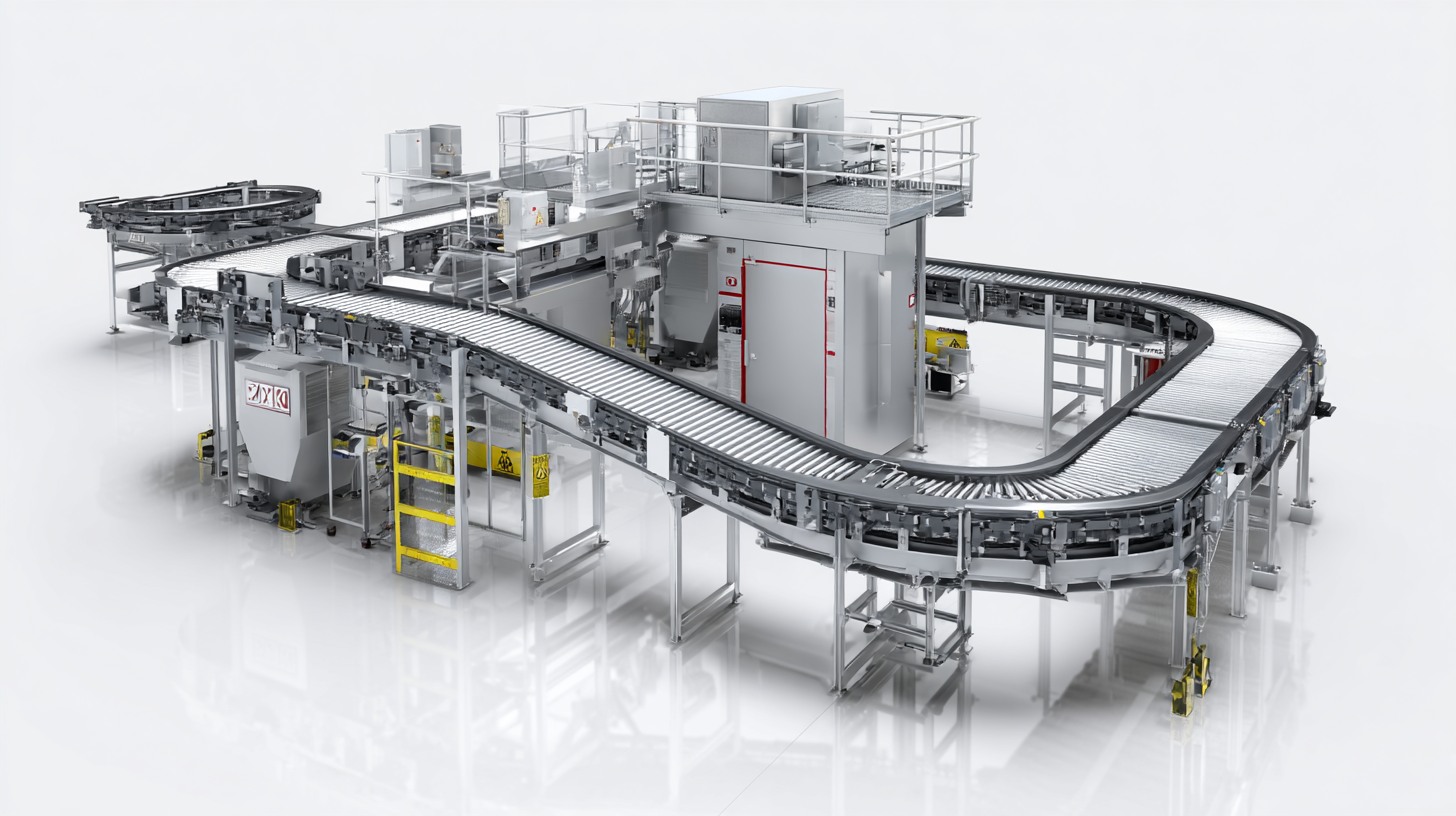

One of the most significant innovations includes the development of modular conveyor systems, which provide greater flexibility in design and operation. These systems can easily adapt to changing production needs and layouts, reducing downtime and facilitating higher throughput rates. Additionally, as sustainability remains a critical focus, manufacturers are increasingly investing in eco-friendly materials and energy-efficient motors, addressing both operational costs and environmental impact. Reports indicate that adopting such sustainable technologies can reduce energy consumption by up to 30%, making them not only economical but also aligned with global green initiatives.

When exploring the realm of modern conveyor machines, understanding their technical specifications is essential for optimizing performance and enhancing efficiency in industrial environments. Conveyor machines serve various functions, from material handling to assembly line production, and their specifications typically include factors such as load capacity, speed, and dimensions. These technical specs determine not only the suitability of a machine for specific tasks but also its longevity and operational costs.

For instance, a conveyor's load capacity must align with the weight of items being transported, while its speed should match production requirements without causing delays or bottlenecks.

Moreover, the integration of advanced technologies is revolutionizing conveyor systems. Features such as variable speed drives, smart sensors, and automated controls significantly improve functionality and adaptability. These innovations require users to be well-versed in understanding how to leverage such specifications effectively. Choosing a conveyor machine equipped with the right technology can enhance workflow automation, reduce labor costs, and provide real-time data for efficient management. Understanding the interplay between these specifications is crucial for companies looking to invest wisely in their industrial infrastructure, ensuring they select machines that not only meet current needs but also grow with future demands.

When selecting the right conveyor machine for your operations, it's crucial to consider several key factors that can significantly impact efficiency and productivity. According to a 2023 report by the Material Handling Industry of America, conveyor systems can reduce labor costs by approximately 30% while increasing operational efficiency by up to 50%. Understanding your specific needs, such as the materials you’re handling, the required speed, and the space available, is essential in making an informed decision.

Another critical aspect is the conveyor type that best fits your requirements. For example, belt conveyors are ideal for transporting bulk materials over long distances, while roller conveyors are effective for packaging applications. A recent study from IndustryWeek indicates that companies investing in automated conveyor systems reported a 20% decrease in product handling time. Therefore, conducting a thorough analysis of your workflow and evaluating different systems can lead to significant time and cost savings in the long run.

As we look ahead to the next decade, conveyor systems are poised to undergo transformative changes driven by advancements in technology and shifting industrial needs. One of the most significant trends is the integration of automation and robotics into conveyor systems. This shift enables higher efficiency and flexibility, allowing manufacturers to adapt swiftly to changing production demands while minimizing labor costs. With smart sensors and IoT connectivity, these systems can now collect real-time data, improving maintenance practices and reducing downtime through predictive analytics.

Another key development is the increasing emphasis on sustainability in conveyor design. As industries strive to reduce their carbon footprints, conveyor machines are being engineered with environmentally friendly materials and energy-efficient motors. Innovations like modular designs that allow for easy upgrades and repairs also contribute to this sustainability focus, ensuring longevity and waste reduction. The incorporation of AI and machine learning will not only enhance performance but also help in optimizing energy consumption, ultimately leading to a smarter and greener manufacturing landscape in the years to come.

Proper maintenance is crucial for ensuring the longevity and efficiency of your conveyor equipment. Regular inspections should be a top priority; check for signs of wear and tear on belts, rollers, and other moving parts. This proactive approach not only helps prevent unexpected breakdowns but also allows you to identify and address minor issues before they escalate into major problems. Utilize a checklist that guides you through each component to ensure nothing is overlooked during your routine checks.

In addition to regular inspections, lubrication plays a vital role in maintaining the performance of conveyor systems. Apply the appropriate lubricants as specified by the manufacturer to keep parts moving smoothly and to reduce friction. Moreover, keeping the conveyor clean is essential; remove any debris or materials that might hinder its operation. Implementing these maintenance tips will not only extend the life of your conveyor machine but will also optimize its efficiency, resulting in smoother operations and reduced downtime.

| Feature | Specification | Maintenance Tips |

|---|---|---|

| Load Capacity | 2000 lbs | Regularly inspect for overloading signs. |

| Belt Width | 24 inches | Clean properly to avoid debris build-up. |

| Speed | 100 ft/min | Check motor and gearbox efficiency every month. |

| Power Supply | 220V, 3-phase | Ensure electrical connections are secure. |

| Frame Material | Steel | Check for rust and apply protective coating. |

| Temperature Range | -20°C to 50°C | Monitor during extreme weather conditions. |