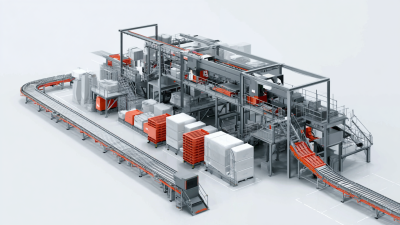

In today's fast-paced logistics environment, the efficiency of warehouse management relies heavily on effective material handling solutions. One critical aspect of this is the implementation of optimized Tire Conveyor and Storage Line systems. According to Dr. Emily Johnson, an expert in industrial automation, "A well-designed Tire Conveyor and Storage Line not only enhances workflow efficiency but also minimizes costs associated with inventory handling." This highlights the growing recognition of advanced conveyor systems in streamlining operations within tire distribution centers.

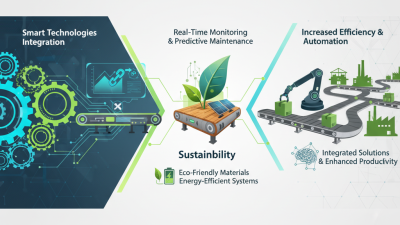

As businesses strive to meet increasing demands while maintaining high levels of service, the integration of reliable Tire Conveyor and Storage Line solutions is becoming essential. These systems are engineered to enhance the flow of tire products, ensure safe storage, and provide seamless transitions between various warehouse processes. By incorporating innovative technologies and flexible designs, companies can efficiently adapt to changing market conditions and improve their overall operational performance.

In conclusion, the significance of a robust Tire Conveyor and Storage Line cannot be understated. It plays a pivotal role in optimizing warehouse management strategies, providing businesses with the agility to respond to evolving challenges. Embracing these solutions not only fosters operational excellence but also positions organizations for sustained growth in the competitive tire industry.

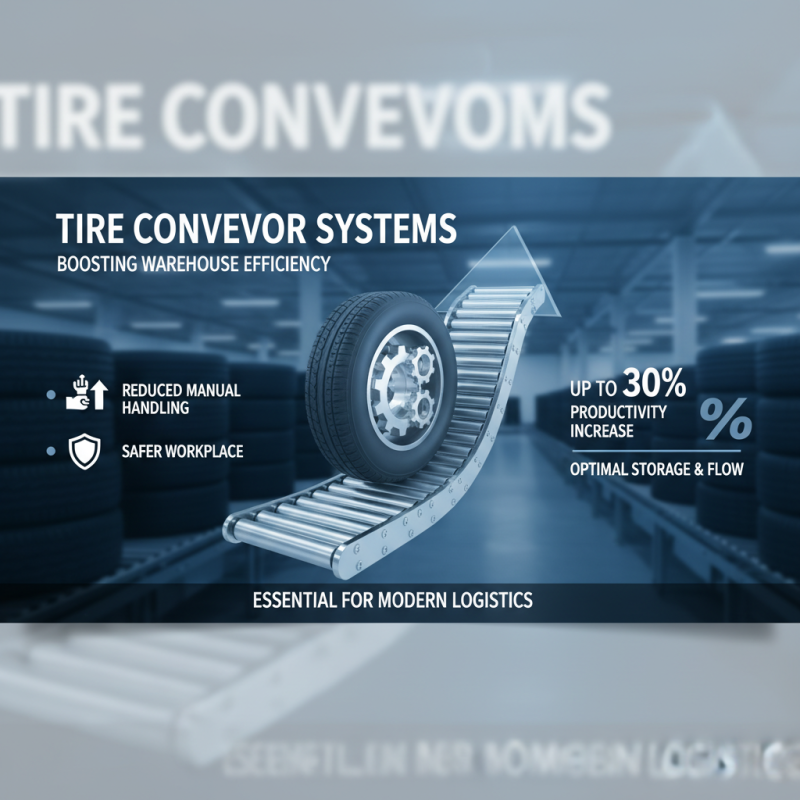

In warehouse management, the integration of tire conveyor systems has become essential for enhancing operational efficiency and ensuring optimal storage solutions. These systems allow for the seamless movement of tires throughout the facility, minimizing manual handling and promoting a safer working environment. According to industry reports, automated conveyor systems can increase productivity by up to 30%, which is crucial in meeting the demands of an ever-evolving market.

Tire conveyor systems provide a variety of solutions, including modular designs that can be easily adapted to different warehouse layouts. This flexibility is critical, as data indicates that over 70% of warehouses are restructured or expanded within their first five years. By incorporating tire conveyors, businesses can significantly reduce the time spent on sorting and shelving items, resulting in faster order fulfillment and improved customer satisfaction.

**Tip:** When implementing a tire conveyor system, consider conducting a thorough analysis of your existing workflow to identify bottlenecks. This evaluation will help tailor the conveyor system to meet specific operational needs, maximizing its efficiency and effectiveness.

Furthermore, effective storage strategies are vital in conjunction with tire conveyor systems. Utilizing vertical space and implementing automated storage and retrieval systems can enhance storage density by up to 40%, minimizing the footprint of tire storage in your warehouse. Such strategies not only improve organization but also facilitate easier access to stock, thereby reducing retrieval times and improving overall productivity.

Tire conveyor solutions play a vital role in modern warehouse management, significantly enhancing the efficiency of storage operations. One of the key benefits of these systems is their ability to optimize space utilization. By employing conveyors, warehouses can maximize vertical and horizontal spaces, allowing for more efficient stocking of tire inventory. This leads to reduced clutter and a more organized environment, ultimately facilitating easier access to products.

Another significant advantage of tire conveyor systems is their capacity to streamline the movement of goods. With automated conveyor lines, tires can be transported quickly and smoothly from one section of the warehouse to another, minimizing manual handling and the associated risks of injury. This not only boosts productivity but also shortens the time required for inventory processing, allowing warehouses to respond faster to customer demands. Moreover, with their efficiency in loading and unloading, tire conveyors help maintain a steady workflow, contributing to overall operational effectiveness.

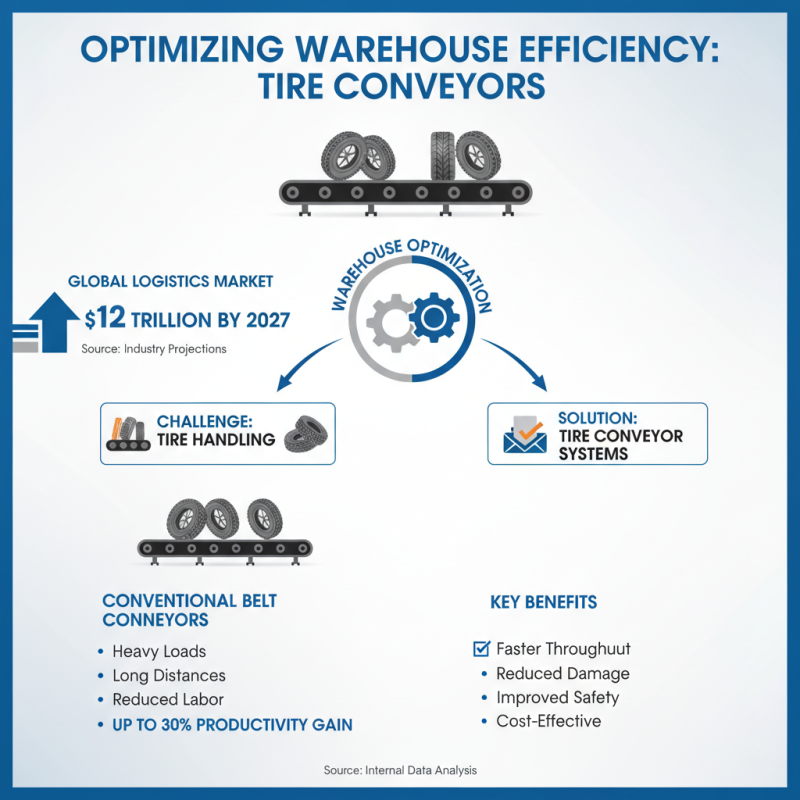

The efficiency of warehouse management is significantly influenced by the types of tire conveyor systems utilized within the facility. With the logistics industry projected to reach a valuation of $12 trillion by 2027, optimizing warehouse operations has never been more crucial. Different conveyor systems cater to varying needs, ensuring smooth and rapid movement of products, which is especially important in tire handling where weight and bulkiness can slow down operations. Conventional belt conveyors, for instance, are excellent for heavy loads and can transport tires over long distances with minimal labor input. Data reveals that integrating these systems can increase productivity by up to 30%.

Moreover, automated conveyor systems, such as those that use roller or chain-driven designs, are becoming increasingly popular in modern warehouses. These solutions offer enhanced flexibility and scalability, allowing for modifications based on fluctuating inventory levels or layout changes. A recent industry report highlighted that warehouses implementing automated solutions experienced a 25% reduction in picking times and labor costs, showcasing the financial benefits of adopting such technologies. As warehouses continue to evolve, understanding the various types of tire conveyor systems will be crucial for businesses striving for optimal efficiency and cost-effectiveness in their operations.

In modern warehouse management, the integration of tire conveyors with Warehouse Management Systems (WMS) is transforming the logistics landscape. Tire conveyors play a crucial role in streamlining the movement of tire inventory, offering speed and efficiency that manual handling simply cannot match. By connecting these conveyor systems with WMS, companies can achieve real-time tracking and management of stock levels, ensuring that tire availability aligns perfectly with operational demands.

Tips: When implementing a tire conveyor system, ensure that it seamlessly integrates with your existing WMS for optimal efficiency. Properly configure your WMS to recognize the unique characteristics of tire inventory, which can vary widely in size and weight.

Moreover, the synergy between conveyor systems and WMS enhances data accuracy and reduces human error. As tire inventory moves through the warehouse, the WMS updates stock levels instantly, allowing for better forecasting and replenishment strategies. This intelligent integration not only saves time but also significantly reduces operational costs associated with overstocking or stockouts.

Tips: Regularly update and train your staff on the integrated systems to ensure they are well-versed in the functionalities, making the most out of the technology. This investment in training fosters a more responsive and adaptable warehouse environment, poised to meet the ever-evolving demands of the market.

| Solution Type | Features | Capacity (Tires/Hour) | Integration Capability | Warehouse Management System |

|---|---|---|---|---|

| Modular Conveyor System | Flexible design, easy to expand | 1000 | Yes | Cloud-based WMS |

| Automated Tire Sorting | AI-driven sorting algorithms | 800 | Yes | On-premise WMS |

| High-Density Storage Rack | Maximized vertical space utilization | 600 | Limited | Integrated with ERP |

| Mobile Tire Handling | User-friendly interface, easy mobility | 500 | Yes | None |

| Real-Time Inventory Tracking | RFID and barcoding technology | Variable | Yes | Cloud-based WMS |

Implementing tire conveyors in logistics operations can significantly enhance efficiency and streamline workflow in warehouse management. One of the best practices involves conducting a thorough assessment of the existing warehouse layout and material handling processes. This evaluation allows companies to identify bottlenecks and determine the optimal placement of conveyor systems to facilitate smooth tire movement. Adopting modular conveyor solutions that can be adjusted to meet future demands is also crucial. This flexibility ensures that the logistics operation can evolve alongside changing business needs, minimizing disruption during upgrades.

Another key practice is focusing on employee training and engagement. Proper training equips staff with the knowledge to operate the new systems effectively, reducing downtime and the risk of accidents. It's vital to create a culture where employees feel comfortable providing feedback on the conveyor system's performance. Regular communication and training sessions can help staff adapt to new technologies and encourage them to share innovative ideas for improving operations.

Additionally, implementing routine maintenance schedules for conveyor systems ensures they operate at peak efficiency, further enhancing overall productivity within the warehouse.