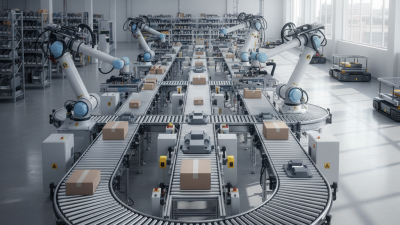

In today's rapidly evolving industrial landscape, the implementation of Automation Conveyor Systems has become a crucial factor in enhancing operational efficiency and driving productivity. According to a report by Grand View Research, the global conveyor systems market was valued at approximately $7.73 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028. This growth is largely fueled by the increasing demand for operational automation in manufacturing and logistics, as businesses strive to minimize costs and optimize workflows.

Automation Conveyor Systems not only streamline the movement of goods but also reduce the risk of human error and improve workplace safety. A study by Automation World highlighted that companies investing in automation technologies, including conveyor systems, have observed a significant reduction in lead times and improved inventory management. Furthermore, the integration of smart technologies within these systems can lead to real-time monitoring and enhanced data analysis, enabling manufacturers to make informed decisions that further boost efficiency.

As industries continue to embrace automation, understanding how to optimize these conveyor systems is imperative for maintaining a competitive edge. In the following sections, we will delve into the top ten tips for refining your Automation Conveyor Systems, ensuring you harness their full potential and elevate your operational capabilities.

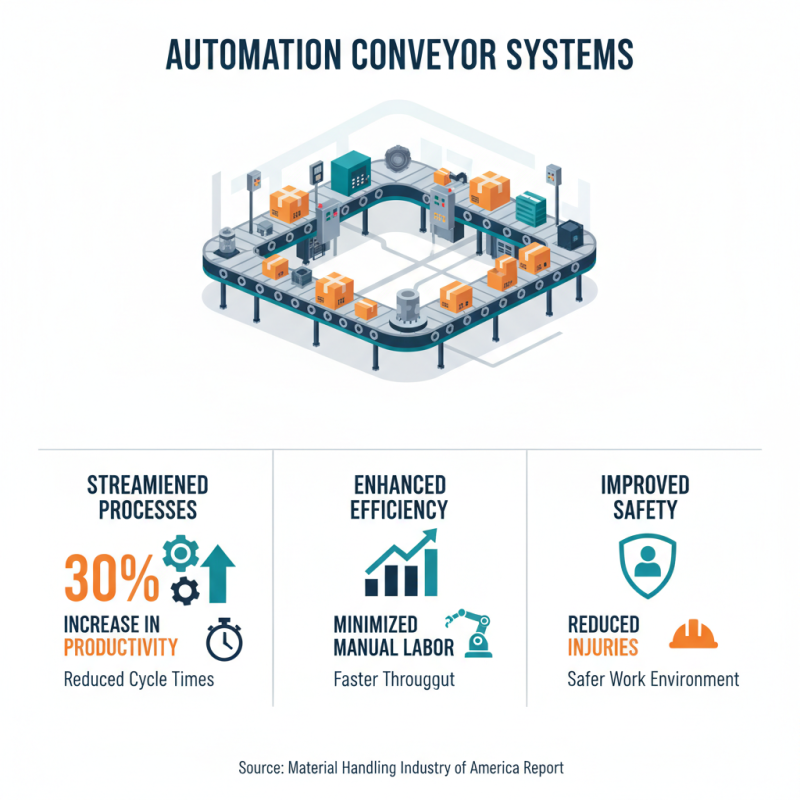

Automation conveyor systems play a pivotal role in modern manufacturing and material handling, streamlining processes and enhancing overall efficiency. According to a report from the Material Handling Industry of America, companies utilizing automated conveyor systems experience up to a 30% increase in productivity due to reduced cycle times and minimized manual labor. These systems not only enhance operational efficiency but also improve workplace safety by reducing the potential for employee injuries associated with manual material handling.

To optimize the use of automation conveyor systems, it's essential to implement several key tips. First, conduct a comprehensive analysis of your workflow to identify bottlenecks and inefficiencies. This will help you tailor your conveyor system to meet specific operational demands. Additionally, regular maintenance is crucial; a study by the International Journal of Industrial Automation suggests that routine inspections can decrease downtime by as much as 25%. Lastly, employee training should not be overlooked—equipping staff with the necessary skills to operate and troubleshoot the conveyor system can significantly enhance both performance and productivity.

Understanding the importance of automation conveyor systems is crucial for businesses looking to remain competitive in today's fast-paced market. As reported by the International Federation of Robotics, the adoption rate of automated solutions grows at an annual average of 15%, underscoring the necessity for industries to integrate these technologies to achieve greater efficiency and cost savings. Implementing smart technologies, like IoT-enabled conveyor systems, further augments their value by providing real-time data analytics, which can guide decision-making and process improvements.

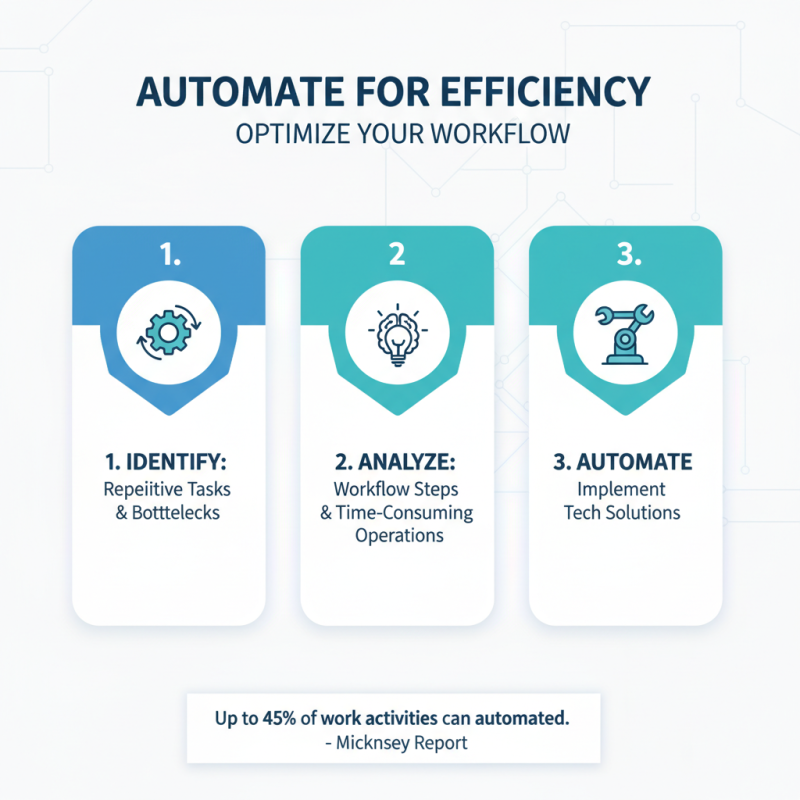

Identifying areas for automation within your workflow is crucial for optimizing efficiency in any operation. According to a report by McKinsey, up to 45% of the activities individuals are paid to perform could potentially be automated by adapting currently demonstrated technologies. This means that organizations must meticulously evaluate their existing processes to uncover repetitive tasks or bottlenecks that could benefit from automation. Conducting a thorough analysis of each workflow step helps in recognizing mundane or time-consuming operations, which can lead to significant efficiency gains.

An effective approach to evaluating your workflow involves mapping out the entire process to visualize task interdependencies and timelines. For instance, a study from the International Society of Automation indicates that automating logistics and material handling processes can reduce operational costs by as much as 30%. Furthermore, automation not only streamlines processes but also minimizes human error, enhancing overall productivity. By utilizing sophisticated data analytics tools, businesses can track performance metrics and identify which areas are underperforming, thus providing insights into where automation can have the greatest impact. Embracing these strategies will pave the way for a more efficient and resilient operation.

When it comes to choosing the right conveyor system, understanding the different types and features available is crucial for optimizing your operational efficiency. There are several conveyor types such as

belt conveyors, roller conveyors, and modular conveyors, each suited for different applications.

For instance, belt conveyors are ideal for transporting bulk materials, while roller conveyors are great for handling packages and boxes. Assessing the specific needs of your operation will help you make the right choice.

Consider the features that can enhance performance when selecting a conveyor system. Look for systems that offer flexibility in design, compatibility with existing machinery, and ease of maintenance. Automated switching features can greatly increase throughput by facilitating smooth transitions between different conveyor segments. Additionally, ensure that the system has a robust safety mechanism to protect workers and equipment alike.

To maximize the benefits of your chosen conveyor system, implement the following tips: First, regularly perform maintenance checks to prevent downtime and ensure smooth operation. Secondly, train your staff to operate the system efficiently, as knowledgeable workers can identify and troubleshoot potential issues early. Lastly, analyze data generated by the conveyor system to identify bottlenecks and optimize workflows continuously, ensuring that your operation is always running at peak efficiency.

Implementing effective maintenance strategies is crucial for optimizing the efficiency of automation conveyor systems. Regular inspections and scheduled maintenance can prevent unexpected breakdowns and extend the lifespan of conveyor components. A proactive approach ensures that machinery operates at peak performance, reducing downtime and improving productivity across operations.

To maintain your conveyor systems effectively, consider the following tips. First, develop a comprehensive maintenance schedule that includes routine checks for wear and tear on belts and motors. Regular lubrication of moving parts can diminish friction and prevent overheating. Additionally, training personnel on proper shutdown and startup procedures helps avoid operational mishaps that can lead to system failures.

Moreover, it’s essential to keep detailed records of maintenance activities. Monitoring and documenting repairs and replacements can identify recurring issues, leading to more informed decisions regarding long-term upgrades or replacements. Consistent monitoring also facilitates identifying potential problems before they escalate, ensuring that your automation conveyor system remains a reliable asset in your production line.

| Tip Number | Tip Description | Expected Outcome | Implementation Difficulty |

|---|---|---|---|

| 1 | Regularly schedule maintenance checks to identify wear and tear. | Increased reliability and reduced downtime. | Medium |

| 2 | Implement a training program for staff on system operations. | Enhanced operational efficiency and safety. | Medium |

| 3 | Utilize sensors for real-time monitoring of system performance. | Proactive issue identification and resolution. | High |

| 4 | Optimize layout for minimal material handling and efficient flow. | Reduced operational costs and time. | Medium |

| 5 | Incorporate maintenance management software for scheduling. | Streamlined maintenance processes and record keeping. | High |

| 6 | Upgrade to energy-efficient conveyor systems where feasible. | Lower energy costs and environmental impact. | Medium |

| 7 | Set key performance indicators (KPIs) for efficiency review. | Data-driven insights for continuous improvement. | Low |

| 8 | Frequent lubrication and parts replacement as per guidelines. | Minimized friction and increased lifespan of components. | Medium |

| 9 | Conduct root cause analysis for recurring issues. | Long-term solutions for common problems identified. | High |

| 10 | Collaborate with engineers for system modifications. | Tailored systems that meet evolving operational needs. | High |

Training staff for effective use of automation conveyor systems is crucial for maximizing the efficiency of any industrial operation. According to a recent report by the Association for Manufacturing Technology, companies that invest in employee training can see productivity improvements of up to 20%. This highlights the importance of not only investing in high-quality automation equipment but also ensuring that staff are equipped with the knowledge and skills to operate and maintain these systems efficiently.

Effective training programs should encompass both theoretical knowledge and practical skills. The Occupational Safety and Health Administration (OSHA) emphasizes that comprehensive training enhances safety and reduces the likelihood of accidents. Studies show that businesses with well-trained employees report 30% fewer workplace incidents, which directly correlates to reduced downtime and increased operational efficiency. Implementing regular training sessions and workshops can empower staff to troubleshoot common issues, resulting in quicker resolutions and minimizing disruptions to workflow.

Moreover, fostering a culture of continuous learning can enhance employee engagement and retention. The National Center for Manufacturing Sciences reports that organizations that actively support worker training experience a 14% lower turnover rate. Engaged employees are not only more adept at operating conveyor systems but also more likely to identify improvements and innovations that can lead to further efficiencies. Investing in employee training is, therefore, not just a strategy for operational excellence but also a vital component of workforce stability and growth.