In today's fast-paced industrial landscape, "Conveyor And Automation" play a critical role in enhancing productivity. Experts emphasize this importance. John Smith, a leading authority in automation solutions, once stated, "Efficiency in operations starts with smart systems." This insight captures the essence of why businesses are turning to these technologies.

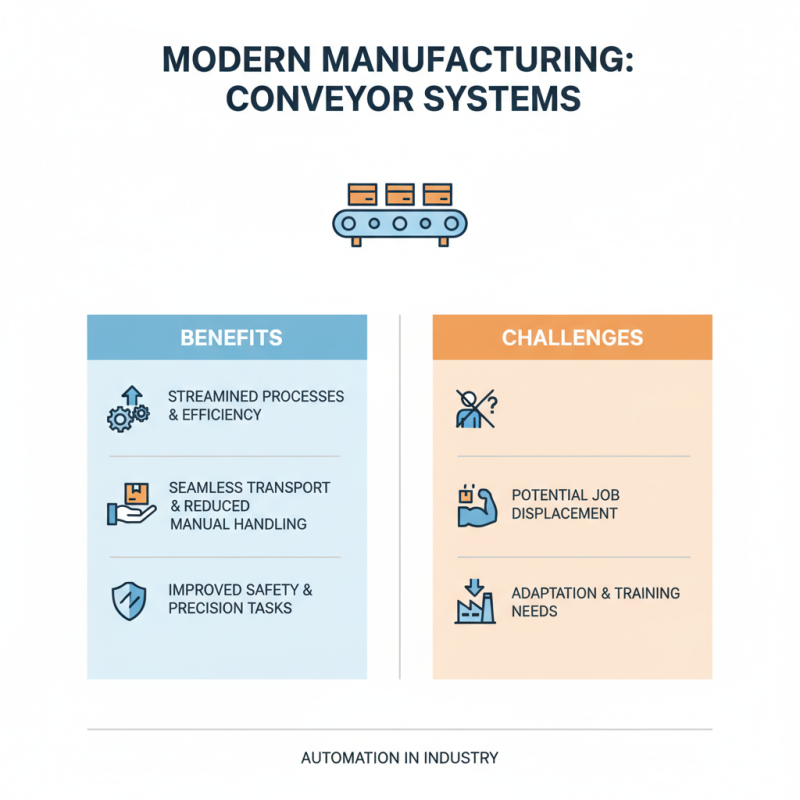

Conveyor systems streamline material handling. They reduce manual labor and minimize errors. Automation adds precise control over processes, ensuring consistency and speed. These benefits are vital in manufacturing and logistics. Yet, some companies hesitate to adopt these innovations. Concerns about high initial costs and implementation challenges often arise.

Despite these hesitations, the advantages are clear. Businesses can see immediate returns on their investment through improved workflows. However, transitioning to automated systems isn’t without its hurdles. Companies must carefully assess their needs and train their teams effectively. The journey toward optimizing "Conveyor And Automation" can be complex, but the rewards are undeniable.

In modern manufacturing, conveyor systems are vital. They streamline processes and improve efficiency. These systems transport goods seamlessly, reducing the need for manual handling. Workers can focus on tasks that require precision and skill. Automated conveyors reduce the risk of injury from repetitive motions. However, they can also lead to job displacement, which is a concern.

One key advantage is their ability to handle various materials. Conveyors can move everything from heavy machinery to fragile items. Their flexibility allows businesses to adapt quickly to market changes. Increased productivity is a common outcome. Yet, relying heavily on automation raises questions about maintenance and malfunction risks. If a conveyor breaks down, production stops. Companies face delays and lost revenue.

Cost savings are another benefit. Automated systems can lower labor costs over time. They reduce the expenditure on manual labor. But, initial investments can be substantial. Additionally, implementing these systems requires proper training for staff. Adapting to new technology may spark resistance. Understanding the advantages and challenges is essential for effective integration.

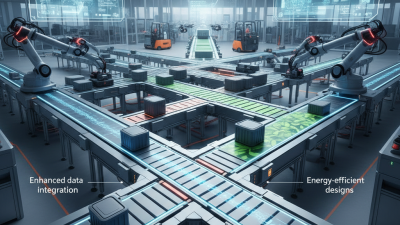

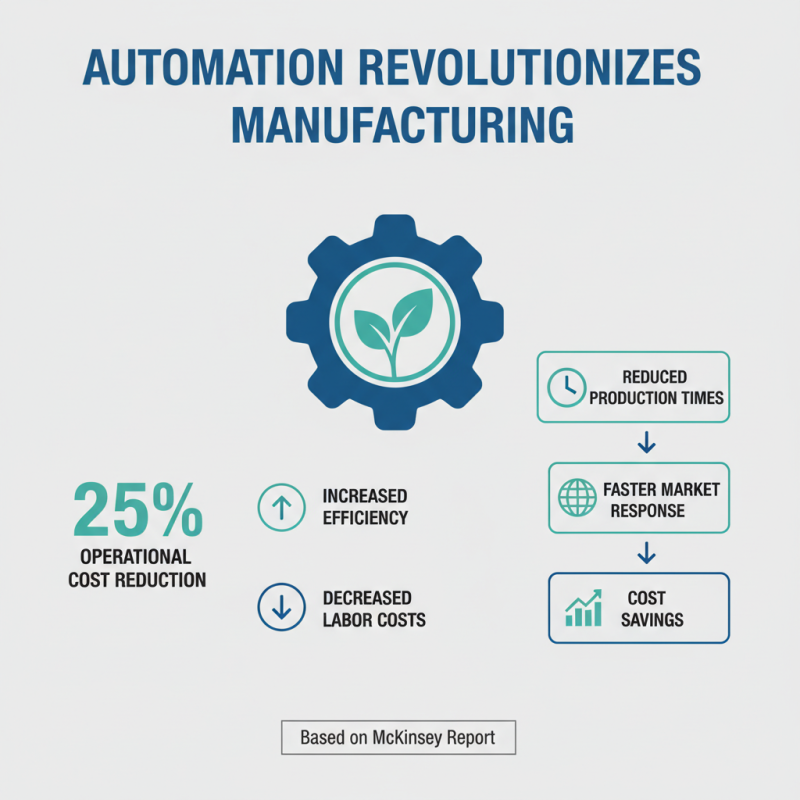

Automation technology has revolutionized the manufacturing landscape, leading to significant cost savings. A report by McKinsey suggests that companies adopting automation can achieve up to a 25% reduction in operational costs. These savings stem from increased efficiency and decreased labor costs. For instance, automated systems can reduce production times, allowing companies to respond faster to market demands.

In the warehouse sector, automation is equally transformative. According to a report from MarketsandMarkets, the global warehouse automation market is projected to reach $30 billion by 2026. This growth reflects how businesses are keen to streamline operations and cut expenses. Automated equipment like conveyor systems can lower manual handling and minimize errors. However, it requires upfront investment, which may be challenging for some small businesses.

While the benefits are clear, companies must also consider the balance between automation and human labor. Over-reliance on automation can lead to job displacements, which necessitates careful planning. Investing in training programs can help mitigate these challenges. Automation isn't just about cost savings; it also involves strategic workforce development and long-term sustainability.

In the battle of automation versus manual processes, productivity stands front and center. Automation systems streamline tasks with precision. They reduce human errors, allowing for consistent outputs. Unlike manual methods, which often falter under repetitive stress, automated systems maintain their efficiency day after day. This leads to significant time savings in manufacturing and logistics operations.

However, it's crucial to consider the balance between machine efficiency and human touch. Automation can lead to over-reliance on technology. Some tasks still benefit from human intuition and creativity. A factory that relies solely on automated systems might miss innovative solutions. Employees might feel less engaged or even threatened by the rise of machines. Integrating both approaches can enhance productivity without sacrificing human insight.

The choice between automation and manual labor brings its own challenges. Training costs for new systems can be substantial. There might be resistance from staff who fear losing their jobs. Yet, the potential for increased output is compelling. Finding that sweet spot can drive success while ensuring a motivated workforce.

Conveyor and automation systems significantly enhance workplace safety. They minimize manual handling, reducing the risk of injuries. Automated systems streamline workflows, ensuring that tasks are completed quickly and safely. Employees can focus on more complex tasks while machines handle repetitive ones.

Incorporating these systems can dramatically lower accident rates. For instance, conveyors prevent heavy lifting. They transport materials smoothly, removing hazards from the floor. Workers can navigate the area without worrying about tripping hazards.

**Tips:** Regularly inspect conveyor systems for any potential malfunctions. Train employees on proper usage to maximize safety. Establish clear pathways around equipment to avoid congestion. Ensure that safety protocols are visible. These simple steps can foster a safer working environment. Remember, an efficient system is only effective if it is safe.

Reliable automation systems play a crucial role in reducing downtime. In a fast-paced manufacturing environment, every second counts. Machines that frequently break down can halt production lines. This leads to delays and financial losses. Industries are increasingly adopting conveyor systems to streamline operations. The efficiency gained can be remarkable, but it's not without challenges.

Automation reduces the chance of human error. Automated systems allow consistent product quality and faster processing times. However, if these systems fail, the impact can be severe. An unexpected breakdown can lead to significant delays. Regular maintenance is essential to keep these systems running smoothly. Neglecting this can create vulnerabilities that affect production reliability.

Investing in automation is not solely about speed. It's also about understanding the lifecycle of the equipment. Training employees on system functions is equally important. A well-trained team can troubleshoot minor issues before they escalate. While embracing automation technologies, companies must remain vigilant about their reliability and maintenance. Otherwise, the dream of flawless production could quickly turn into a nightmare.

| Benefit | Description | Impact |

|---|---|---|

| Reduced Downtime | Automation systems minimize equipment failure and ensure smooth operation. | Increased productivity and higher output consistency. |

| Enhanced Safety | Reduces manual handling, lowering risk of workplace injuries. | Improved employee morale and reduced insurance costs. |

| Cost Efficiency | Automating processes leads to lower labor costs and waste reduction. | Higher profit margins and reinvestment opportunities. |

| Higher Efficiency | Consistent speeds and processes lead to optimized production times. | Significantly increased throughput and reduced cycle times. |

| Quality Control | Automated systems provide consistent quality in production. | Reduced defects and improved customer satisfaction. |

| Flexibility | Automated systems can be easily adapted to new tasks. | Enhanced ability to respond to market changes. |

| Data Collection | Automated systems facilitate accurate data capturing. | Improved decision-making based on real-time insights. |

| Scalability | Systems can be expanded easily to accommodate growth. | Allows businesses to grow without major downtime. |

| Sustainability | Reduced energy consumption and waste through precision. | Enhanced reputation and compliance with regulations. |

| Competitive Advantage | Faster production and better quality can outpace competitors. | Increased market share and stronger positioning. |