In the modern manufacturing landscape, the role of the Conveyor Machine is vital. According to a recent industry report from Grand View Research, the global conveyor system market size was valued at USD 6.50 billion in 2022 and is projected to grow significantly. This growth highlights the increasing need for efficient material handling solutions across various sectors.

Experts like Dr. Sarah Thompson, a leading authority in automated systems, state, "Conveyor Machines enhance productivity by reducing manual labor." This statement underscores how essential conveyors are for optimizing operations. Different types of conveyor machines serve diverse functions—each designed for specific tasks, from heavy-duty transport to delicate handling.

However, many industries still overlook the potential flaws within their conveyor systems. Safety, maintenance, and flexibility are critical aspects needing attention. Ignoring these factors can lead to inefficiencies or increased costs. As we explore the top 10 conveyor machine types, it is crucial to reflect on how each one may impact overall productivity and safety standards.

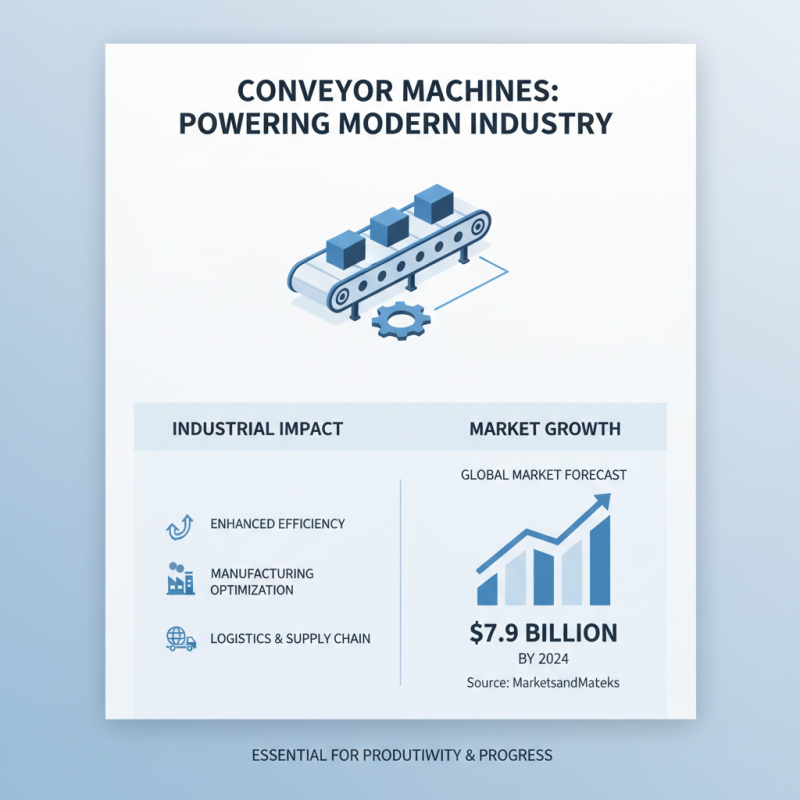

Conveyor machines play a vital role in modern industries. They enhance efficiency in manufacturing and logistics. According to a report by MarketsandMarkets, the global conveyor systems market is expected to reach approximately $7.9 billion by 2024. This growth highlights their increasing value across various sectors.

These systems are crucial for automating processes. They reduce manual labor, minimize human error, and streamline operations. For instance, in the food and beverage industry, conveyors ensure quick and safe transport of products. However, not all conveyor types suit every application. A misalignment can lead to breakdowns and unnecessary downtime.

Moreover, maintenance remains a challenge. A study by Statista reveals that about 30% of conveyor issues stem from improper upkeep. Companies must address this to avoid costly repairs. Investing in training for staff about conveyor operations can prevent such problems. It's essential to recognize that while conveyors speed up processes, they also require careful management.

Conveyor systems are vital in various industries. They streamline operations and enhance efficiency. Understanding different types is essential for optimal use. Here are key types of conveyor systems and their applications.

Belt conveyors are widely used in food processing and packaging. They transport items smoothly over long distances. Roller conveyors support heavy loads, especially in warehouses. These systems allow for easy movement of pallets and large boxes. Furthermore, magnetic conveyors are ideal for transporting metal parts. They minimize accidents with their precise handling.

Tips: When selecting a conveyor system, consider the specific materials you’ll handle. Matching the conveyor type to your needs will maximize efficiency.

In contrast, flexible conveyors adapt to various layouts. They are perfect for temporary setups or seasonal demands. Such versatility allows for quick adjustments. However, they might not support high-capacity loads. Always assess needs versus capabilities to find the right balance.

Tips: Regular maintenance is crucial for conveyor longevity. Scheduling checks can prevent costly downtimes. Operators should be trained to spot issues early, ensuring smooth operations.

Conveyor machines are vital in various industries. They enhance efficiency and streamline operations. Each type offers unique features and benefits. For instance, belt conveyors are widely used in manufacturing. Their flexible design allows for transporting materials over diverse distances. According to a recent industry report, belt conveyors can boost productivity by up to 30%.

Roller conveyors are another popular choice. They excel in moving heavy items with minimal effort. This type requires less power and offers lower maintenance costs. However, they may struggle with smaller products, which can lead to inefficiencies. A study indicated that improper load handling can reduce effectiveness by 15%. This highlights the need for proper training and usage guidelines.

Finally, screw conveyors are effective for bulk materials. They provide a continuous flow and are easy to maintain. Their design is great for transporting powders and granules. However, they may not be suitable for all materials due to potential blockages. Recognizing these limitations is crucial for optimizing their use in processes.

| Conveyor Type | Key Features | Benefits |

|---|---|---|

| Belt Conveyor | Continuous belt, flexible design | Ideal for transporting bulk materials |

| Roller Conveyor | Use of rollers to move items | Great for heavy loads and high efficiency |

| Chain Conveyor | Strong chain links for heavy items | Suitable for heavy loads and harsh environments |

| Bucket Conveyor | Buckets attached to a chain or belt | Efficient for vertical transport of materials |

| Screw Conveyor | Spiral screw mechanism | Great for moving granular and powdered materials |

| Magnetic Conveyor | Magnetized surface for holding metal items | Safe for transporting metal materials in production |

| Overhead Conveyor | Suspended from an overhead track | Space-saving and efficient for assembly lines |

| Vibrating Conveyor | Uses vibration to move materials | Ideal for bulk materials and fragile items |

| Pneumatic Conveyor | Uses air pressure to transport materials | Effective for powdered and granular materials |

| Flexible Conveyor | Can be easily adjusted and moved | Versatile and ideal for temporary setups |

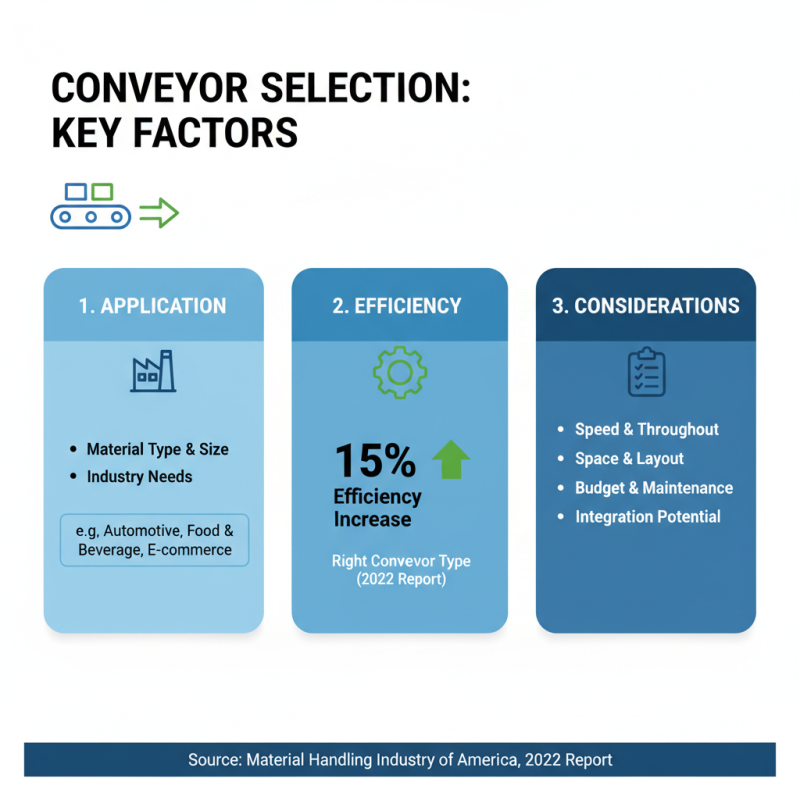

When selecting a conveyor machine, several factors warrant careful consideration. Understanding the specific application is crucial. For instance, industries differ significantly in their material handling needs. According to a 2022 report by the Material Handling Industry of America, companies reported a 15% increase in efficiency when using the right conveyor type for their products.

Weight and size of materials also matter. A conveyor designed for lightweight items may struggle under heavier loads, leading to costly breakdowns. Moreover, speed plays a vital role. Some operations require high-speed handling, especially in e-commerce. However, high speed might compromise accuracy.

Environment is another key factor. Will the conveyor be in a cold storage area or a hot manufacturing zone? A study by the Conveyor Equipment Manufacturers Association highlights that environmental factors can influence performance by up to 20%. Neglecting these details could lead to unexpected performance issues. Always reassess your choices to ensure they align with changing operational needs.

Conveyor systems are crucial in many industries. With increasing reliance on these machines, maintenance is vital to ensure safety and efficiency. According to a report by the Conveyor Manufacturers Association, improper maintenance can lead to costly downtimes. In fact, approximately 60% of conveyor-related accidents stem from lack of maintenance. Regular checks can prevent these issues.

Routine inspections should include belt alignment and tension. Many operators overlook the importance of these basic checks. Skipping them may lead to greater problems down the line. Bearings and pulleys also require attention. A study indicated that improper lubrication of these components can reduce equipment life by 30%.

Safety measures must be a priority. Employees should undergo regular training on conveyor systems. Studies show that well-trained staff can reduce accidents by up to 50%. Clear signage and guards can also minimize risks. However, some facilities lack the necessary safety measures. This negligence can result in serious injuries, affecting both workers and productivity. Regular audits can help identify and mitigate these risks.

This chart displays the number of units in use for various types of conveyor machines. Understanding these conveyor types is essential for maintenance and safety practices in industrial settings.