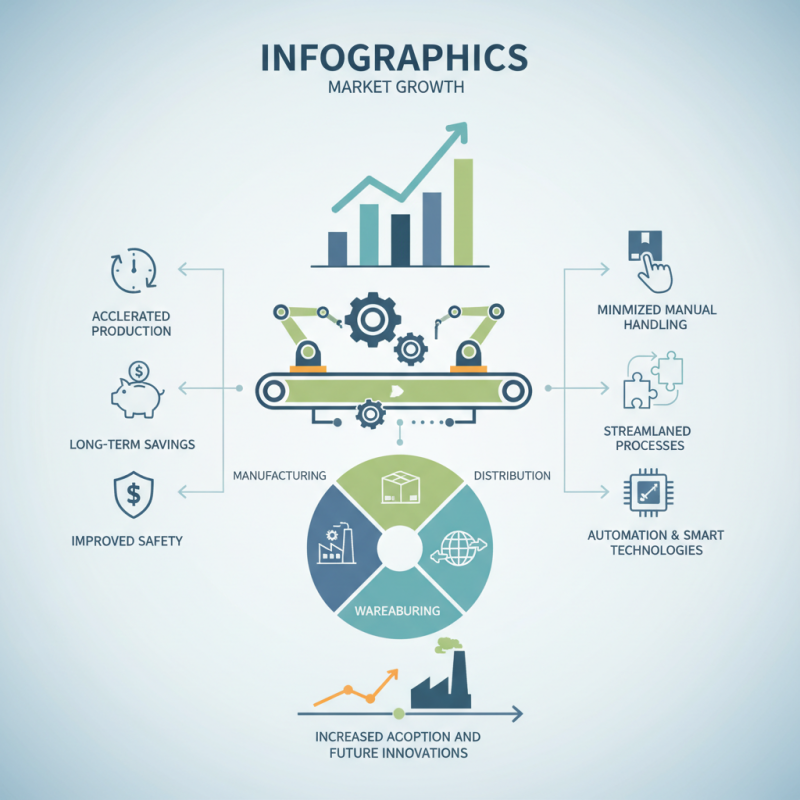

In today's fast-paced industrial landscape, the significance of efficient material handling solutions cannot be overstated. Conveyor systems have become a cornerstone for optimizing logistics and productivity across various sectors. According to recent industry reports, the global conveyor systems market is projected to reach USD 9.2 billion by 2025, with a compound annual growth rate (CAGR) of 4.2% from 2020 to 2025. This demonstrates the growing reliance on automated systems to enhance operational efficiency and reduce labor costs.

Conveyor Systems Limited, a pivotal player in this domain, embodies the advancements in technology that are reshaping the material handling industry. From manufacturing to warehousing, and even to distribution, the versatile applications of conveyor systems allow businesses to streamline processes, minimize manual handling, and improve safety standards. Implementing conveyor systems not only accelerates production cycles but also provides substantial long-term savings, making them an indispensable element for modern enterprises striving for competitiveness in their respective markets. With the ongoing evolution of automation and smart technologies, the adoption of conveyor systems is expected to surge, driving further innovations and efficiencies across industries.

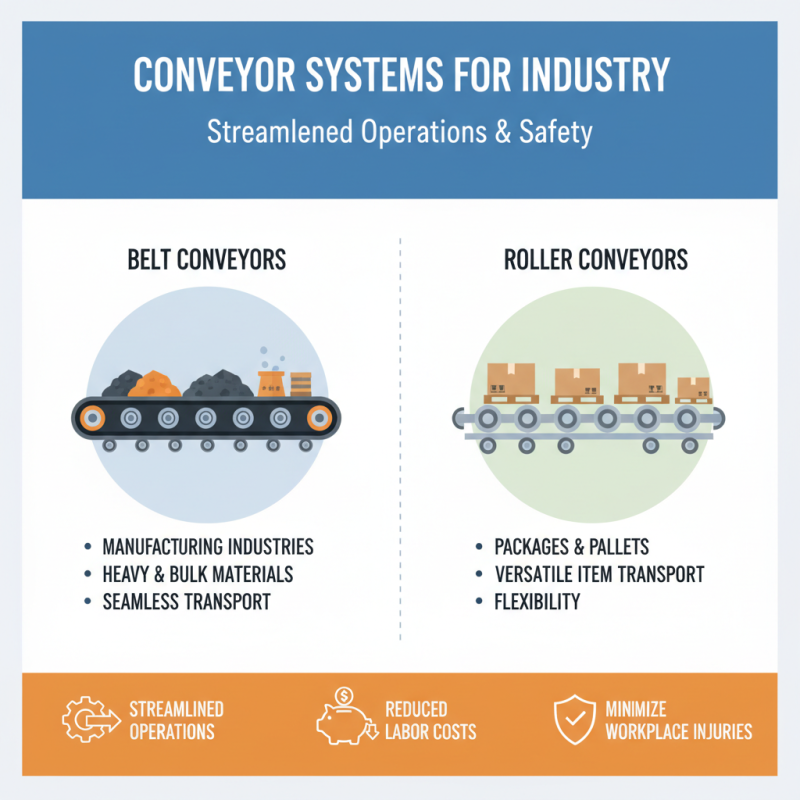

When considering conveyor systems for various industries, it's crucial to understand the types available and their specific applications. For manufacturing industries, belt conveyors are a popular choice due to their ability to transport heavy and bulk materials seamlessly along a defined path. In addition, roller conveyors are ideal for handling packages or pallets, providing flexibility in transporting a wide range of items efficiently. These systems promote streamlined operations, reducing labor costs and minimizing the risk of workplace injuries.

In the food and beverage industry, stainless steel conveyors offer the hygiene and durability required to meet stringent safety standards. They are designed to withstand the rigors of frequent cleaning while ensuring that products are transported safely without contamination. Similarly, for warehousing and distribution centers, modular conveyor systems can be customized to fit specific layouts and processes, enhancing space utilization and productivity.

Tips for selecting the right conveyor system include assessing the specific needs of your operation, considering the types of materials to be moved, and evaluating the space available. Always prioritize systems that improve efficiency and reduce downtime. Furthermore, do not overlook the importance of ease of maintenance and the potential for scalability in your chosen conveyor solution. Such strategic considerations will undoubtedly lead to optimal performance and growth in your business.

Implementing conveyor systems in your business can lead to substantial efficiency gains and cost reductions. According to a report by the Material Handling Industry of America, integrating these systems can increase productivity by up to 30%. By automating the transport of materials, companies are able to minimize manual handling, which not only speeds up the process but also significantly decreases the risk of workplace injuries. This reduction in accidents can result in lower insurance costs and decreased downtime, contributing to smoother operations.

Moreover, conveyor systems are highly versatile, adapting to various industries such as manufacturing, warehousing, and distribution. They facilitate continuous flow and sorting of goods, enhancing logistics performance. A study by the Warehousing Education and Research Council indicates that businesses utilizing conveyor systems can improve order fulfillment rates by up to 50%. The ability to streamline inventory management by efficiently moving products through different stages of processing ultimately leads to better service levels and increased customer satisfaction, making conveyor systems an essential investment for any forward-thinking business.

Conveyor systems play a crucial role in enhancing operational efficiency and productivity across various industries. By automating the movement of goods, they minimize manual handling, reduce labor costs, and streamline workflow processes. This automation not only saves time but also significantly lowers the risk of human error, which can lead to costly delays and safety hazards. Moreover, conveyor systems can be customized to fit any production line, ensuring that they meet specific business needs while maintaining a seamless operation.

Tips: To maximize the benefits of conveyor systems, consider integrating sensor technology that monitors the flow and movement of products. This real-time data can help identify bottlenecks and inefficiencies, enabling quick adjustments to optimize performance. Additionally, regular maintenance and routine inspections are essential to prolong the life of the system and ensure it operates at peak efficiency.

Furthermore, conveyor systems offer flexibility in handling various types of materials, from small parts to large packages. This adaptability is vital for businesses that frequently change their product lines or volume requirements. By implementing modular systems, companies can easily expand or modify their setups as needed, resulting in a more dynamic and responsive production environment.

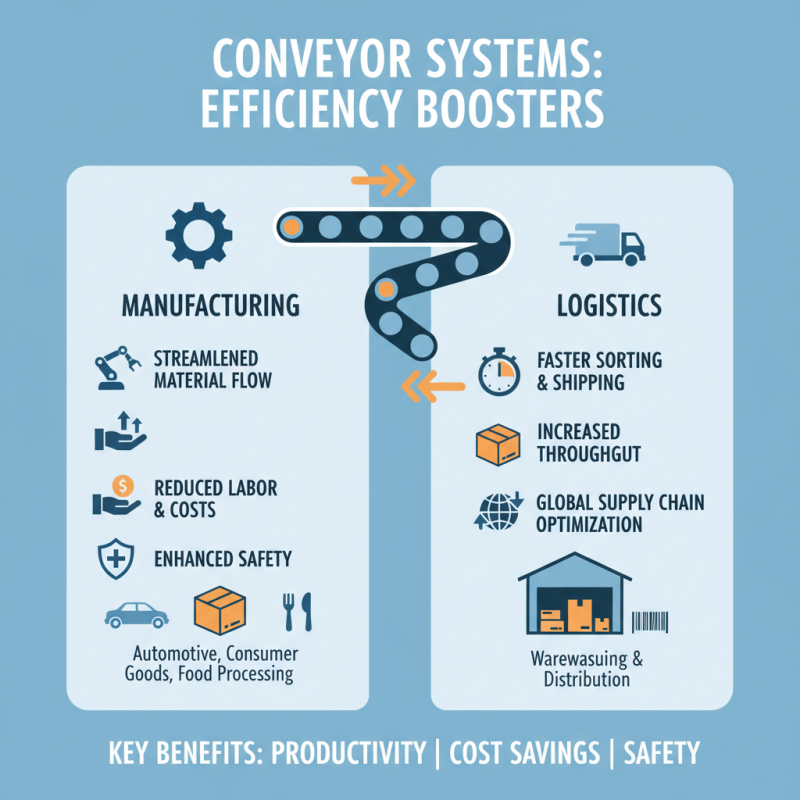

Conveyor systems play a crucial role in enhancing efficiency across various sectors, particularly in manufacturing and logistics. In manufacturing, these systems streamline the movement of materials and components, reducing manual handling and increasing productivity. By automating the transportation of heavy or bulky items, conveyor belts not only minimize labor costs but also lower the risk of workplace injuries. Industries such as automotive, consumer goods, and food processing utilize conveyor systems to ensure a smooth workflow, maintaining high production rates while adhering to strict safety standards.

In logistics, conveyor systems are essential for optimizing storage and distribution operations. They facilitate the swift movement of goods through warehouses and sorting facilities, improving order fulfillment times and reducing operational bottlenecks. By integrating conveyor systems into logistics processes, companies can enhance inventory management, enabling real-time tracking and efficient sorting of products. The ability to adapt conveyor designs to specific tasks, such as accumulating, merging, or diverting products, allows businesses to tailor their operations to meet diverse shipping and handling requirements, ultimately leading to improved customer satisfaction.

When considering a conveyor system for your business, several factors are critical to ensure you choose the right solution tailored to your operational needs. First and foremost, the type of materials you handle and their specific characteristics play a significant role in this decision. According to a 2021 report by the Material Handling Industry of America, over 50% of manufacturing operations have switched to automated conveyor systems primarily to accommodate diverse product types, including bulk materials, packages, and components. This versatility in handling a range of materials provides businesses with enhanced operational efficiency and flexibility.

Another essential consideration is the layout of your workspace. The design of your facility can significantly influence the type of conveyor system that best fits your needs. For instance, in environments with limited space, a modular conveyor system may be more suitable, allowing for easy reconfiguration as operations evolve. A report from the Conveyor Equipment Manufacturers Association highlighted that 70% of businesses that integrated space-efficient conveyor systems saw a 25% increase in overall efficiency. Furthermore, assessing the load capacity and speed requirements helps in selecting a conveyor system that optimally serves your throughput without compromising safety and reliability. By evaluating these factors thoughtfully, businesses can optimize their material handling processes and drive productivity.

| System Type | Key Benefits | Common Applications | Considerations |

|---|---|---|---|

| Belt Conveyor | Versatile, low maintenance, efficient for bulk materials | Food processing, manufacturing, mining | Weight of materials, length of conveyor, environment |

| Roller Conveyor | High load capacity, easy to modify, suitable for packages | Distribution centers, packaging lines | Type of goods, operational speed, maintenance needs |

| Screw Conveyor | Compact design, good for dry bulk materials, low cost | Agriculture, food production, wastewater treatment | Material characteristics, installation space |

| Chain Conveyor | High durability, heavy load handling, suitable for harsh conditions | Automotive manufacturing, scrap handling | Impact loads, environmental factors |

| Elevating Conveyor | Space-saving, enables vertical transport, efficient | Food industry, bottling plants, warehouses | Height limitations, material type |