In the ever-evolving landscape of industrial operations, the need for efficiency and productivity has never been more paramount. As companies strive to streamline their processes, designed conveyor systems have emerged as a vital component in enhancing operational effectiveness. According to a report by the Material Handling Industry of America, the implementation of automation solutions, including designed conveyors, can lead to productivity gains of over 30 percent. This remarkable statistic underscores the transformative power of advanced conveyor systems in modern manufacturing and logistics.

The year 2023 has witnessed a significant shift toward engineered conveyor systems tailored to meet specific operational demands. These systems not only optimize space utilization but also reduce labor costs and minimize the risk of manual handling injuries. In fact, a study from the International Society of Automation highlights that organizations incorporating smart conveyor technology can experience a reduction in operational costs by as much as 20 percent while simultaneously improving throughput. As we look ahead to 2025 and beyond, it is evident that investing in designed conveyor solutions will be crucial for businesses aiming to stay competitive in a rapidly changing market. The strategic adoption of these systems promises not only enhanced efficiency but also a robust return on investment in the years to come.

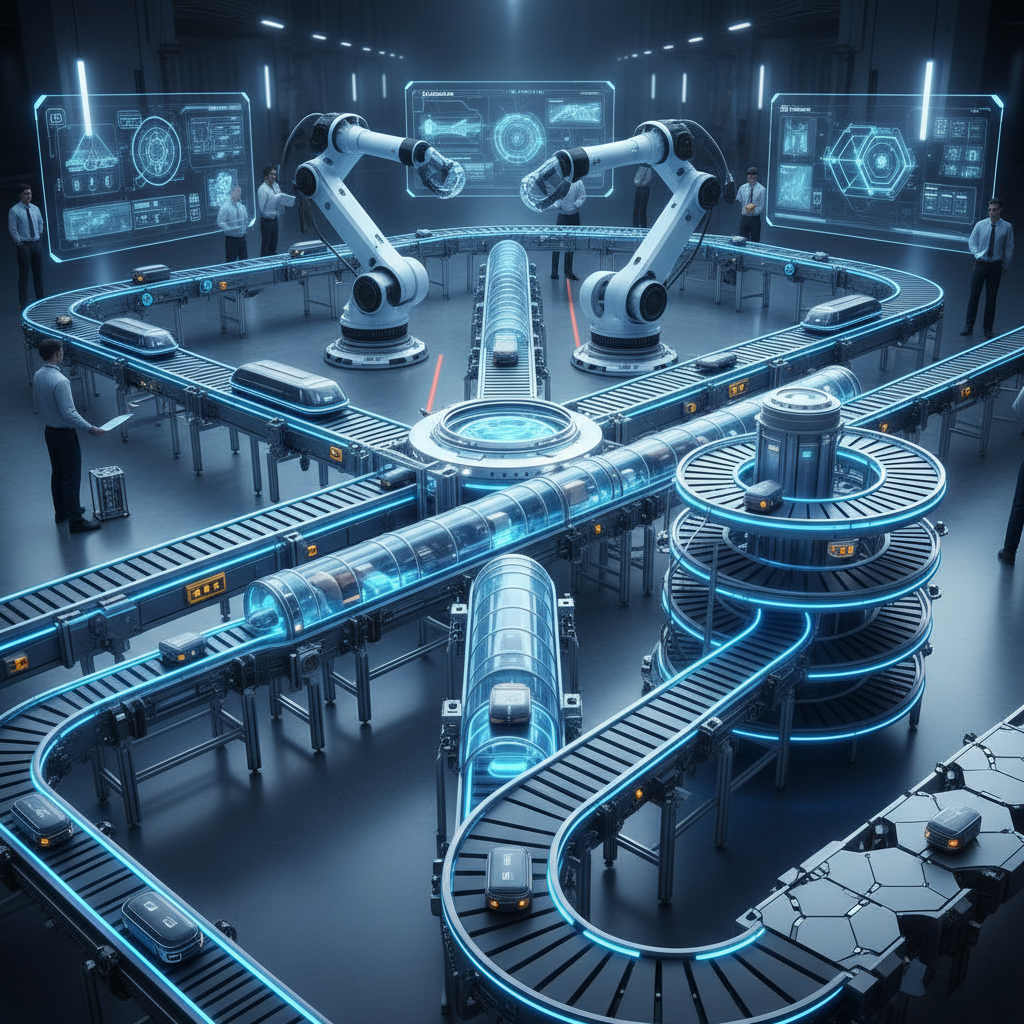

In 2023, innovative conveyor design trends are reshaping the landscape of material handling, leading to exceptional boosts in efficiency. One of the most significant advancements involves modular conveyor systems, which allow for flexible configuration and easy scalability. These systems can be quickly adapted to different production needs, dramatically reducing downtime and enhancing overall workflow. By incorporating smart technology, such as IoT sensors and AI-driven analytics, companies can optimize conveyor performance in real-time, ensuring that bottlenecks are addressed proactively.

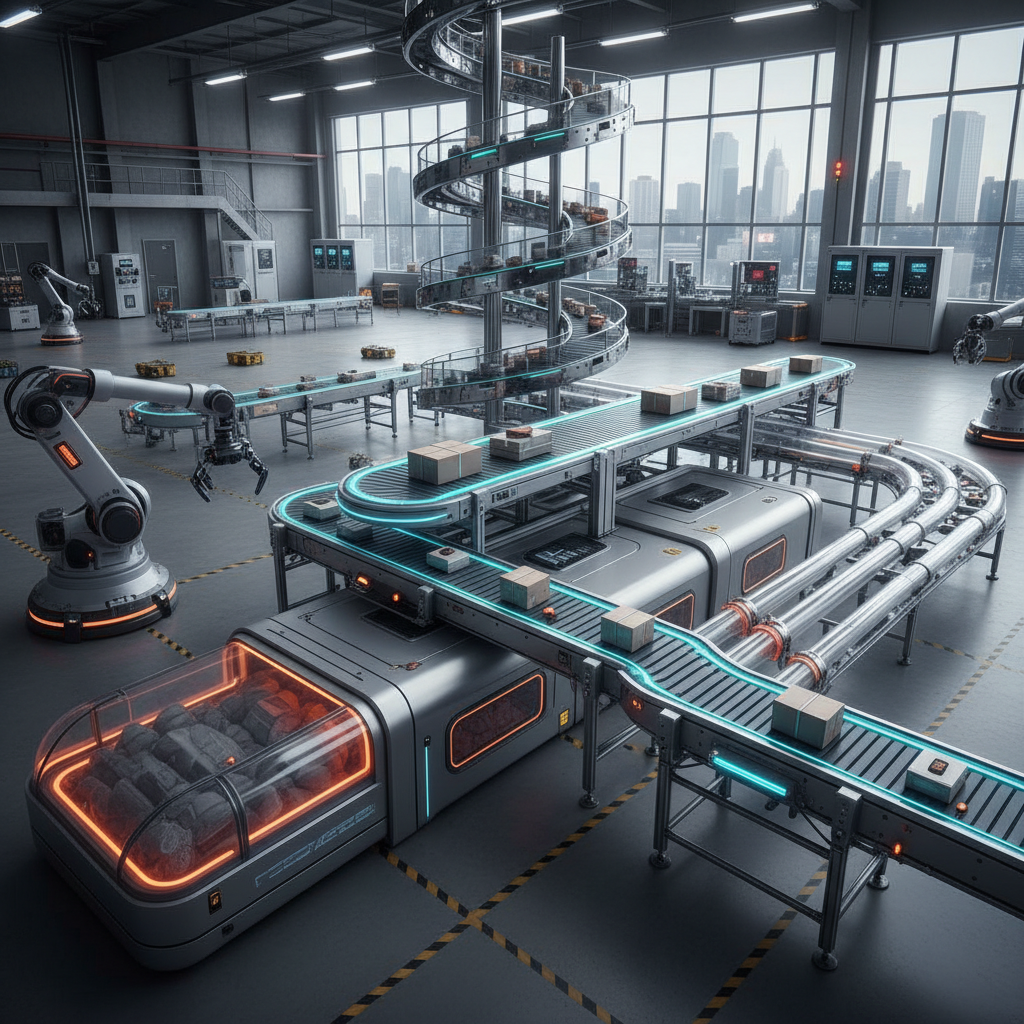

Another trend gaining traction is the integration of sustainable materials and designs in conveyor systems. Manufacturers are increasingly prioritizing environmentally friendly solutions that not only minimize waste but also improve system longevity. Advanced conveyor belts made from recycled materials and energy-efficient motors are now common, reducing energy consumption by significant margins. Additionally, the implementation of automated guided vehicles (AGVs) in conjunction with traditional conveyor systems ensures a seamless operation, ultimately driving efficiency gains of over 30 percent across various industries. These transformative designs not only streamline operations but also pave the way for a more sustainable approach to manufacturing and logistics.

This bar chart illustrates the efficiency improvements of the top five conveyor systems designed in 2023, showcasing their effectiveness in operational efficiency enhancements.

In 2023, customizable conveyor systems have emerged as a key driver of productivity enhancements in various industries. These tailored solutions allow businesses to design conveyor configurations that specifically meet their operational needs, leading to efficiency boosts of over 30 percent. By adapting conveyor speed, layout, and capacity to the unique workflow of a facility, companies can minimize bottlenecks and streamline the movement of goods. The flexibility of these systems ensures that they can evolve alongside changing demands, making them a valuable investment for manufacturers seeking sustained growth.

Furthermore, the integration of advanced technologies such as IoT sensors and AI-driven analytics into customizable conveyor systems has elevated their performance. Real-time monitoring capabilities enable businesses to track conveyor efficiency and predict maintenance needs, thereby reducing downtime. With the ability to fine-tune every aspect of the system, from incline angles to speed variations, manufacturers are not only optimizing throughput but also creating a safer work environment. This level of customization promotes a more efficient and safer production line, ultimately leading to higher output and improved profitability.

In 2023, the integration of smart technology into conveyor systems has revolutionized the manufacturing and logistics sectors, leading to efficiency boosts of over 30 percent. These advanced systems incorporate features like AI-driven predictive maintenance, real-time data analytics, and automated adjustments that allow for seamless operation. By utilizing machine learning algorithms, these smart conveyors can anticipate potential breakdowns before they happen, reducing downtime and maintenance costs. This proactive approach not only enhances productivity but also significantly extends the lifespan of the equipment.

Moreover, smart conveyor systems leverage the Internet of Things (IoT) to facilitate enhanced performance. Sensors embedded within the systems collect vast amounts of data, providing operators with insights into material flow, speed, and wear levels. This data-driven approach enables companies to optimize workflows and make informed decisions regarding supply chain management. By automating routine tasks and allowing for remote monitoring, businesses can act swiftly to address issues as they arise, ultimately streamlining operations and increasing overall efficiency. As more industries adopt these innovative conveyor solutions, the landscape of manufacturing continues to evolve, paving the way for greater productivity and competitiveness in the global market.

| Rank | Conveyor System Type | Efficiency Increase (%) | Smart Technology Integration | Industry Application |

|---|---|---|---|---|

| 1 | Modular Belt Conveyor | 35% | IoT Sensors for Real-time Monitoring | Food Processing |

| 2 | Automated Guided Vehicle (AGV) | 40% | AI Path Optimization | Manufacturing |

| 3 | Overhead Conveyor System | 32% | Automated Controls for Load Balancing | Automotive |

| 4 | Belt Conveyor with Variable Speed | 33% | Smart Speed Control | Mining |

| 5 | Spiral Conveyor | 31% | Predictive Maintenance Technology | Retail |

As industries increasingly seek to balance efficiency with environmental responsibility, eco-friendly conveyor systems are leading the charge in sustainable design. These innovative systems prioritize the use of recyclable materials and energy-efficient technologies, significantly reducing the carbon footprint of operations. For instance, conveyor systems that incorporate solar power or kinetic energy recovery systems can dramatically lower energy consumption, providing a dual benefit of cost savings and sustainability.

Moreover, manufacturers are adopting modular designs that allow for easy upgrades and modifications, ensuring that these systems remain adaptable as technology evolves.

This flexibility not only enhances overall efficiency but also extends the lifecycle of the equipment, aligning with sustainability goals.

By opting for eco-friendly conveyor options, businesses can boost productivity while contributing to a greener planet, embodying the modern approach that intertwines efficiency with ecological mindfulness.

In recent years, several industries have leveraged advanced conveyor systems to significantly enhance operational efficiency. One standout case is a large automotive manufacturing plant that implemented a custom-designed conveyor system, reducing assembly line bottlenecks by over 35%. By using smart sensors and automated sorting mechanisms, the facility not only increased production speed but also minimized labor costs, showcasing the profound impact of tailored conveyor solutions.

Another compelling success story comes from a leading e-commerce company that faced challenges with order fulfillment during peak seasons. By integrating a modular conveyor system designed for rapid scalability, they achieved a 40% increase in order processing efficiency. This system utilized AI-driven algorithms to optimize package routing, resulting in faster delivery times and improved customer satisfaction levels. These real-world examples highlight how innovative conveyor designs can transform productivity, ultimately setting new benchmarks in their respective sectors.