In the dynamic world of manufacturing and logistics, the efficiency of material handling plays a crucial role in the overall productivity and success of a business. Industrial Conveyor Systems have emerged as indispensable tools in optimizing workflows, managing inventory, and ensuring smooth transportation of materials across various production stages. With their ability to enhance operational efficiency while reducing labor costs and minimizing the risk of workplace injuries, these systems are vital to modern industrial operations.

Choosing the right Industrial Conveyor Systems for your specific needs can be a daunting task, given the plethora of options available in the market. Factors such as the type of materials being handled, the layouts of your facilities, and the overall production processes must be carefully considered. This article aims to provide a comprehensive overview of the top 10 Industrial Conveyor Systems, exploring their features, benefits, and ideal applications. By understanding the different types of conveyor systems and their respective functionalities, businesses can make informed decisions, ensuring the chosen solution aligns perfectly with their operational goals and enhances their competitive edge in the market.

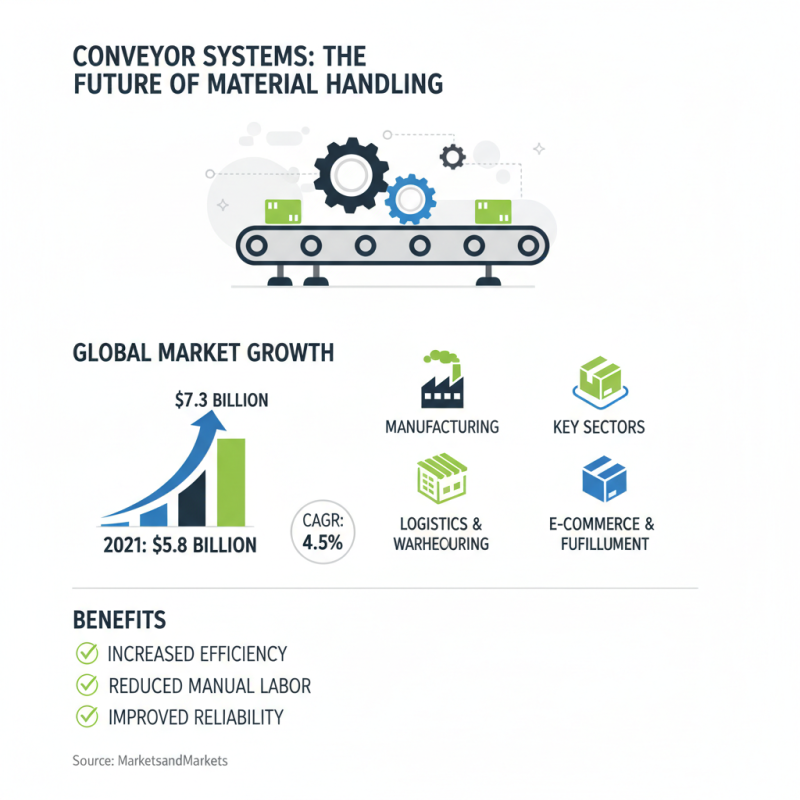

Conveyor systems play a critical role in modern industrial operations, providing efficiency and reliability for material handling across various sectors. According to a report by MarketsandMarkets, the global conveyor systems market is expected to reach $7.3 billion by 2026, growing at a CAGR of 4.5% from 2021. This growth reflects the increasing need for streamlined operations and reduced manual handling in industries ranging from manufacturing to logistics.

There are several types of conveyor systems, each designed for specific applications. For instance, belt conveyors are commonly used for bulk material handling due to their ability to transport large quantities over considerable distances. Roller conveyors are favored in package handling and distribution centers, enabling quick movement of goods while facilitating easy loading and unloading. Additionally, modular conveyors are gaining traction due to their versatility and customization options, making them an excellent fit for automated production lines. As reported by Technavio, advancements in automation and the adoption of smart technology are further driving the evolution of conveyor systems, paving the way for improved efficiency and lower operational costs.

Understanding the specific requirements of your business is essential when selecting the right conveyor system. Factors such as load capacity, the type of materials being transported, and the layout of the facility must all be considered. Industry data highlights that companies that invest in tailored conveyor solutions can achieve up to a 50% increase in operational efficiency, underscoring the importance of making informed choices in conveyor system selection.

When selecting the right industrial conveyor system for your business, several key factors should be considered to ensure optimal efficiency and productivity. First and foremost, the type of material being transported plays a crucial role in the decision-making process. Different materials require specific systems that can accommodate their weight, size, and handling characteristics, such as whether they are loose, packaged, or fragile. Additionally, understanding the environmental conditions, such as temperature and humidity, can help in choosing a conveyor system that is durable and reliable.

Another critical consideration is the layout and available space within your facility. Analyzing the flow of materials and processes helps determine the configuration of the conveyor system—whether it will be straight, curved, or multi-level. Flexibility is also essential, as your business may grow or change over time. Choosing a modular conveyor system that can be easily reconfigured or expanded as your needs evolve will save time and resources in the long run. Furthermore, evaluating the maintenance demands of the conveyor system is vital; a system that requires less frequent maintenance will reduce downtime and increase overall productivity.

When selecting the right conveyor system for your business, it is essential to understand the various features and benefits that different systems provide. According to a report by the Conveyor Equipment Manufacturers Association, the global conveyor system market is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth highlights the increasing reliance on efficient and customizable conveyor solutions across various industries, including manufacturing, food processing, and logistics.

One of the primary features to consider is the type of material used in the conveyor system. For instance, belt conveyors are ideal for transporting bulk materials, while roller conveyors are better suited for heavy goods. Each type presents distinct advantages, such as reduced wear and tear or enhanced speed and efficiency in material handling. Additionally, automated conveyor systems integrated with IoT technology can significantly optimize workflow, reduce human error, and improve safety. A report from Allied Market Research states that the automation of industrial processes is expected to increase productivity by 20% to 30%, making investment in advanced conveyor solutions a strategic move for businesses looking to enhance operational efficiency.

Moreover, flexibility in system design is another crucial benefit. Customizable conveyor systems can adapt to varied layouts, product types, and changes in production demands. This adaptability not only supports a smoother operational flow but also allows businesses to scale their processes as needed. Research by Grand View Research indicates that the need for versatile and space-efficient conveyor systems is pushing companies to invest more in modular conveyor designs, which can save valuable floor space while maximizing output. These features, combined, empower businesses to choose conveyor systems that align best with their unique operational needs and growth strategies.

The chart below illustrates the features and benefits of the top 10 industrial conveyor systems, focusing on throughput capacity, energy efficiency, and maintenance requirements.

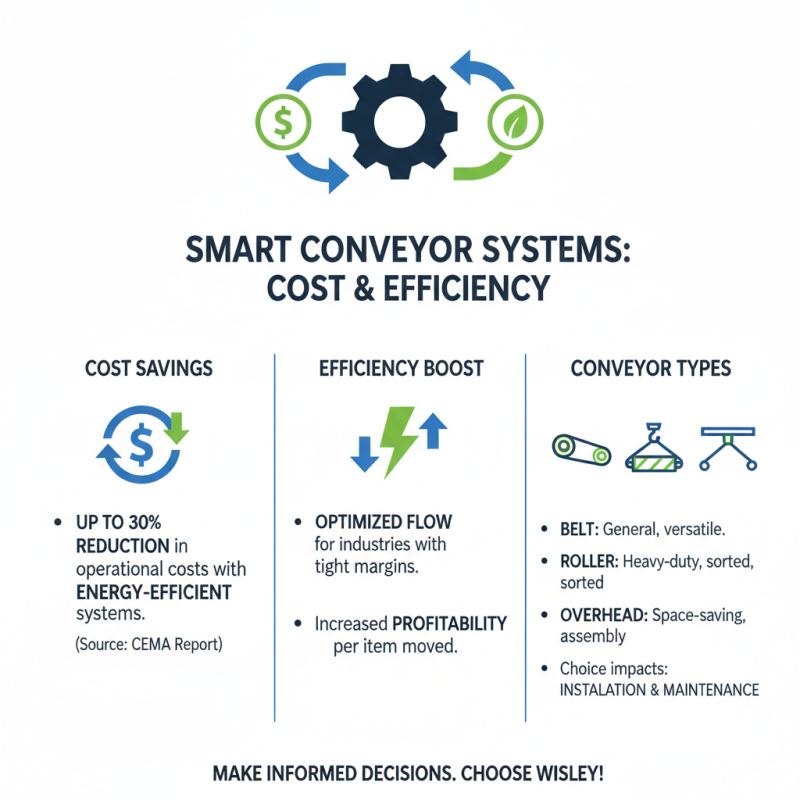

When considering industrial conveyor systems for your business, it’s vital to evaluate both costs and efficiency to make an informed decision. According to a recent report from the Conveyor Equipment Manufacturers Association, energy-efficient conveyor systems can reduce operational costs by up to 30%. This is particularly significant for industries that operate on a tight margin, where every dollar saved can contribute to overall profitability. Moreover, the choice of conveyor type, whether belt, roller, or overhead, can drastically impact both installation and maintenance costs.

Tips: When comparing different conveyor solutions, conduct a thorough cost-benefit analysis that takes into account not just the purchase price but also the long-term operational costs and potential energy savings. Integrating automation into your conveyor systems can also enhance efficiency, leading to quicker throughput times and reduced labor costs.

Different conveyor solutions also vary in their efficiency ratings. A study from the National Institute of Standards and Technology indicated that optimizing conveyor speed and load can lead to enhancements in productivity by as much as 25%. By selecting a conveyor system that matches the specific needs of your material handling processes, you can ensure that you are maximizing both performance and return on investment. Remember to assess the scalability of your chosen system, as future business growth may necessitate an upgrade or expansion of your conveyor capabilities.

Implementing conveyor systems in a business environment requires careful planning and consideration of several factors to ensure optimal efficiency and safety. According to an industry report by the Material Handling Industry of America, the adoption of conveyor systems can increase productivity by up to 30% and reduce labor costs significantly. This is particularly critical in sectors such as manufacturing, warehousing, and logistics, where streamlined material handling can lead to faster turnaround times and improved overall operational effectiveness.

Maintaining these systems is equally important; regular inspections and maintenance can prevent costly downtime. A study from the Conveyor Equipment Manufacturers Association indicates that proactive maintenance can extend the life of conveyor systems by as much as 50%. Organizations should develop a comprehensive maintenance plan that includes scheduled checks, cleaning, and timely repairs to ensure that the systems operate at peak performance.

Additionally, leveraging data analytics can provide insights into system performance and highlight areas needing attention, allowing for informed decision-making regarding upgrades or replacements.