In today’s fast-paced manufacturing landscape, understanding Industrial Conveyor Systems is crucial. These systems streamline operations, reduce costs, and enhance productivity. According to a report by Research and Markets, the industrial conveyor market is expected to reach $8.4 billion by 2025. This growth highlights the increasing dependency on efficient transportation solutions in industries.

Expert John Smith, a leading consultant in automated systems, emphasizes, “Conveyor systems are the backbone of modern manufacturing.” His insight reveals that many companies overlook the importance of integrating advanced conveyor technology. The right system can significantly reduce bottlenecks and improve workflow efficiency.

Despite the benefits, many organizations still rely on outdated conveyor solutions. They often encounter challenges related to maintenance and flexibility. Investing in modern Industrial Conveyor Systems not only mitigates these issues but also prepares businesses for future demands. As industries evolve, rethinking conveyor strategies will become essential for sustainable growth and competitiveness.

Industrial conveyor systems are vital in many sectors. They streamline processes and boost productivity. Understanding their various types and applications is crucial for efficiency.

One common type is belt conveyors. They move heavy goods over long distances. According to industry reports, approximately 70% of manufacturing facilities employ this type. They are efficient for transporting bulk materials like grains or coal. However, maintenance is essential. Regular checks prevent breakdowns and costly downtime.

Another type is roller conveyors. These are useful for packaging and sorting. They can handle items of varying sizes. A study by a logistics research firm noted that roller conveyors reduce handling time by 50%. However, they may not be suitable for heavy loads, which can cause wear and tear.

**Tips**: Always consider the load capacity of each system. An overloaded conveyor can lead to inefficiencies and failures. Regular training of staff can enhance system utilization. Constantly evaluate your needs; what works today may not fit tomorrow's demands.

This chart illustrates the various types of industrial conveyor systems and their applications across different industries. The data showcases the prevalence of each conveyor type based on industry usage:

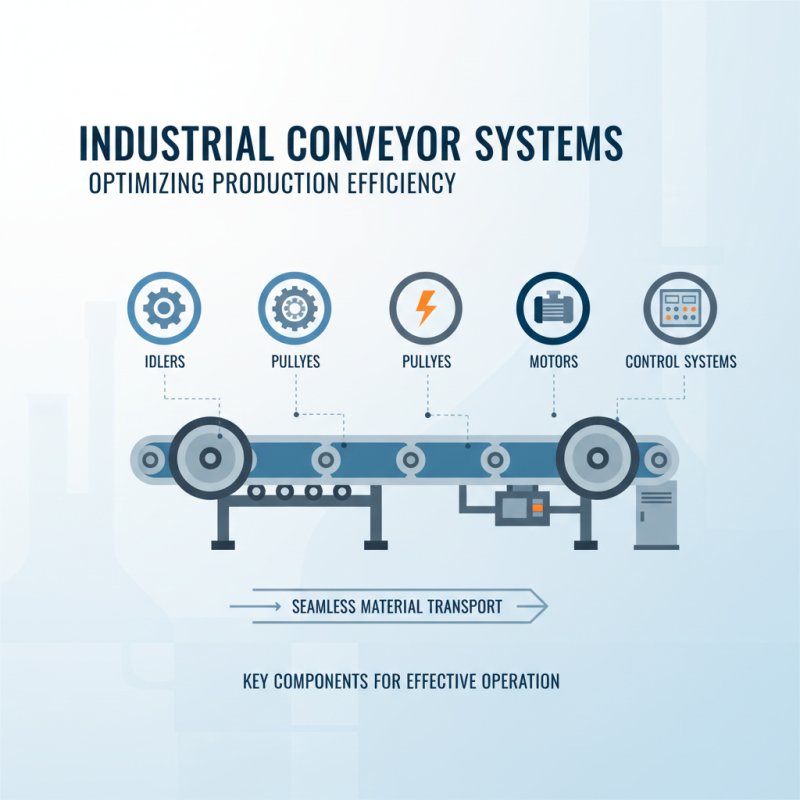

Industrial conveyor systems play a crucial role in optimizing production efficiency. Understanding their key components is vital for effective operation. A conveyor system typically includes idlers, pulleys, motors, and control systems. These components work together to transport materials seamlessly across various stages of manufacturing.

Idlers support the conveyor belt and ensure proper alignment. They play a crucial role in maintaining tension and can significantly impact the system’s efficiency. According to industry reports, poorly functioning idlers can lead to a 30% increase in energy consumption. Motors power the system, while control systems manage the speed and direction. A well-calibrated control can minimize wear and tear on the conveyor, enhancing overall lifecycle.

Regular maintenance of these components is essential but often neglected. Many companies overlook small wear issues until they escalate. This can lead to costly downtimes. Balancing efficiency and maintenance should be a fundamental focus. Ignoring these key components may lead to operational inefficiencies. In a dynamic industrial landscape, understanding these elements is critical for staying competitive.

In industrial settings, conveyor systems have become essential. They streamline processes and boost efficiency. These systems handle materials with ease. This can reduce manual labor, which can lead to fewer injuries. The cost savings from automating material transport are significant. Companies can invest in other areas to improve growth.

Tips: Consider using adjustable conveyor heights. This can make it easier for staff to access materials. Also, ensure regular maintenance to avoid breakdowns.

Another advantage is the flexibility of design. Conveyor systems can adapt to different layouts. They can manage various products, from heavy items to small components. However, not all facilities maximize their potential. It’s important to assess current setups and look for improvements. Regular audits can highlight areas needing attention. Inefficient layouts can waste time and money. No system is perfect, and reflection on workflow is key.

Tips: Train employees on the system’s capabilities. Familiarity can lead to better use of the equipment. Also, solicit feedback from staff to find blind spots.

When it comes to conveyor systems, maintenance is essential. Over 30% of unscheduled downtime in manufacturing is due to equipment failure, according to recent industry reports. Keeping a conveyor system running efficiently can save both time and money. Proper maintenance can extend operational life by up to 50%.

Tips: Regularly inspect the belts and rollers for wear. Check alignment frequently. Misalignment can lead to excessive wear and reduced efficiency. Lubricate moving parts as per manufacturer guidelines. Neglecting this can lead to friction and increased energy costs, with studies indicating a reduction in energy efficiency by up to 20% if maintenance is overlooked.

Environmental factors need consideration. Dust accumulation can interfere with system performance. Keep the conveyor area clean to prevent material buildup. In one study, maintenance practices that included cleaning increased overall efficiency ratings significantly. Proper training for personnel on maintenance protocols can make a noticeable difference in performance. Ignoring these aspects can lead to avoidable failures.

| Conveyor Type | Load Capacity (lbs) | Speed (ft/min) | Material | Maintenance Frequency (months) |

|---|---|---|---|---|

| Belt Conveyor | 2000 | 100 | Rubber | 6 |

| Roller Conveyor | 1500 | 50 | Steel | 12 |

| Chain Conveyor | 3000 | 60 | Plastic | 8 |

| Bucket Conveyor | 2500 | 40 | Steel | 10 |

| Magnetic Conveyor | 1800 | 70 | Steel | 5 |

| Slat Conveyor | 2200 | 30 | Plastic | 11 |

| Incline Conveyor | 2000 | 80 | Rubber | 9 |

| Overhead Conveyor | 1500 | 50 | Aluminum | 7 |

| Portable Conveyor | 1000 | 40 | Rubber | 6 |

| Vibrating Conveyor | 1700 | 30 | Steel | 12 |

In recent years, conveyor systems have undergone significant advancements. Emerging technologies are driving innovation in their design and functionality. Companies are exploring smart solutions to improve efficiency and reduce operational costs. These systems are becoming more adaptable to various industries, from manufacturing to packaging.

Automation is at the forefront of these changes. Intelligent sensors collect real-time data, allowing for predictive maintenance. This helps reduce downtime and minimizes unexpected failures. In addition, energy-efficient motors are being integrated into designs. This plays a crucial role in lowering energy consumption, though the initial costs can be higher.

Modularity is another important aspect of modern conveyor systems. Customizing components allows for flexibility in design. However, this can create challenges in ensuring compatibility. Balancing adaptability with standardization is vital in the design process. Companies need to evaluate their specific needs carefully. Emphasizing innovation while addressing practical concerns remains a complex yet essential part of developing effective conveyor solutions.