In the fast-paced manufacturing landscape, the efficiency of Assembly Conveyor Systems plays a pivotal role in enhancing productivity and reducing operational costs. According to a report by the Material Handling Industry of America, optimizing these systems can lead to significant improvements, with studies indicating a potential increase in efficiency by up to 30%. As industries strive to meet higher demand and improve throughput, understanding the intricacies of conveyor system optimization becomes crucial. This includes evaluating factors such as layout design, load distribution, and maintenance practices. By adhering to proven strategies outlined in "The Ultimate Checklist for Optimizing Your Assembly Conveyor Systems Efficiency," manufacturers can not only streamline operations but also empower their teams to focus on adding value to their processes, thereby driving overall business success.

In the fast-paced manufacturing landscape, the efficiency of Assembly Conveyor Systems plays a pivotal role in enhancing productivity and reducing operational costs. According to a report by the Material Handling Industry of America, optimizing these systems can lead to significant improvements, with studies indicating a potential increase in efficiency by up to 30%. As industries strive to meet higher demand and improve throughput, understanding the intricacies of conveyor system optimization becomes crucial. This includes evaluating factors such as layout design, load distribution, and maintenance practices. By adhering to proven strategies outlined in "The Ultimate Checklist for Optimizing Your Assembly Conveyor Systems Efficiency," manufacturers can not only streamline operations but also empower their teams to focus on adding value to their processes, thereby driving overall business success.

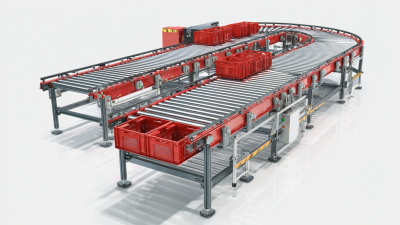

In today's competitive manufacturing landscape, the efficiency of assembly conveyor systems plays a pivotal role in the overall productivity and success of operations. Understanding this importance requires awareness of how these systems interlink with broader supply chain management (SCM). Effective SCM not only optimizes production processes but also streamlines the distribution of products, ensuring that raw materials move smoothly from suppliers all the way to the end consumer. By enhancing the efficiency of assembly conveyor systems, manufacturers can significantly reduce costs and meet customer demands more effectively.

Emerging technologies are driving this optimization. The rise of Industry 4.0 has revolutionized conveyor technology, integrating advanced automation and AI solutions. These innovations enable factories to monitor and adjust their operations in real time, leading to faster throughput and improved quality. As automation reshapes the manufacturing sector, understanding the role of assembly conveyor systems in this ecosystem becomes crucial. By focusing on optimizing these systems, manufacturers can harness the full potential of modern technologies and stay ahead in a rapidly evolving market.

To optimize the performance of assembly conveyor systems, it is crucial to track specific key metrics that directly impact efficiency. According to recent industry reports, conveyor systems that monitor downtime, throughput, and cycle times can improve operational efficiency by up to 40%. For instance, using advanced data analytics tools can help identify bottlenecks in real-time, allowing for immediate corrective actions that minimize disruptions in production flow.

Additionally, focusing on maintenance metrics such as Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) is vital. Companies that have implemented predictive maintenance strategies report a 25% reduction in maintenance costs and a significant decrease in unplanned downtime. This proactive approach not only enhances the reliability of conveyor systems but also supports the continuous production processes required in sectors like manufacturing and logistics.

The recent advancements in smart conveyor technologies, with companies developing innovative solutions like automated and intelligent transport systems, further illustrate the importance of such metrics. Reports suggest that integrating IoT capabilities allows for better data collection and predictive analytics, leading to a more streamlined operation and improved overall productivity. The continuous evolution in this field underlines the necessity for companies to adapt and optimize their conveyor systems strategically.

Maintaining the efficiency of assembly conveyor systems is crucial for any manufacturing operation, and regular, essential maintenance plays a significant role in prolonging the lifespan of these systems. According to a report by the Conveyors & Automation Systems Association, effective maintenance can extend the life of conveyor systems by up to 50%. This underscores the importance of establishing a robust maintenance schedule that includes regular inspections, cleaning, and timely replacement of wear components.

One of the most effective maintenance practices is to implement a predictive maintenance strategy. Utilizing technology such as vibration analysis and thermal imaging can help identify potential issues before they escalate into costly breakdowns. A study by the U.S. Department of Energy found that predictive maintenance strategies can reduce operational costs by approximately 20% while improving reliability. Regularly lubricating moving parts and checking alignment can also prevent wear and tear, ensuring that the conveyor system continues to operate at peak efficiency and extends its operational longevity.

This bar chart displays the efficiency percentages of various essential maintenance practices for assembly conveyor systems. Monitoring and optimizing these practices can significantly prolong the lifespan of your conveyor systems.

Innovative technologies are transforming the landscape of conveyor systems, leading to enhanced efficiency and productivity in assembly operations. One of the most notable advancements is the integration of smart sensors and IoT technology, which allows for real-time monitoring of conveyor performance. These sensors can detect bottlenecks or mechanical issues before they escalate into serious problems, ensuring that the entire system runs smoothly. By leveraging data analytics, businesses can gain insights into operational patterns, enabling them to optimize workflows and reduce downtime.

Additionally, advancements in automation are revolutionizing conveyor systems. The introduction of AI-powered robotics is enhancing the precision and speed of material handling, allowing for seamless integration between different stages of the assembly line. These robots can work collaboratively with human operators, taking on repetitive tasks while workers focus on more complex processes. Furthermore, automated guided vehicles (AGVs) are being utilized for transporting materials within facilities, streamlining the logistics of production and increasing overall efficiency. As these innovative technologies continue to evolve, companies can expect to see significant improvements in their conveyor system operations, ultimately driving greater productivity and cost savings.

When optimizing assembly conveyor systems, avoiding common mistakes can significantly enhance efficiency and productivity. One prevalent error is neglecting the importance of regular maintenance. Conveyor systems are intricate machines that require consistent checks and adjustments to function optimally. Failing to schedule routine inspections often leads to unexpected breakdowns, which can cause costly downtime and disrupt the entire assembly line. Establishing a maintenance routine not only keeps the systems running smoothly but also extends their lifespan.

Another frequent mistake is overlooking the importance of proper training for operators. Without adequate training, employees may not understand how to manage or troubleshoot conveyor systems effectively. This lack of knowledge can lead to inefficient operations and even damage to the equipment. Investing in comprehensive training programs helps ensure that team members know the best practices for using the conveyor systems, ultimately maximizing their efficiency and minimizing errors. Taking the time to address these common pitfalls can lead to a more productive assembly process and a smoother workflow overall.

| Common Mistake | Description | Impact on Efficiency | Recommendation |

|---|---|---|---|

| Neglecting Maintenance | Failing to perform regular maintenance can lead to breakdowns. | High downtime and increased repair costs. | Implement a scheduled maintenance plan. |

| Overloading the System | Exceeding weight limits can strain components. | Increased wear and tear; potential for failures. | Follow manufacturer's load guidelines strictly. |

| Inefficient Layout | Poor placement can cause bottle-necks in processes. | Reduced throughput and increased cycle times. | Conduct a layout optimization review. |

| Ignoring Automation | Not utilizing available automation technologies. | Missed opportunities for increased efficiency. | Invest in automation solutions where applicable. |

| Lack of Employee Training | Under-trained staff can lead to operational issues. | Errors in operation that lead to inefficiencies. | Implement regular training programs for staff. |