In the rapidly evolving industrial landscape, conveyor machines play a pivotal role in enhancing operational efficiency across numerous sectors. According to a recent report by Grand View Research, the global conveyor system market size was valued at over $7 billion in 2022 and is expected to grow at a CAGR of 4.6% from 2023 to 2030. This growth is driven by the increasing need for automation and streamlined processes in manufacturing and logistics. However, not all conveyor machines are created equal; the quality and performance can vary significantly based on design, material, and supplier expertise.

In this blog, we will explore how to identify the best conveyor machine suppliers in the industry, ensuring that businesses invest in reliable and efficient equipment that meets their specific needs.

As we approach 2025, the conveyor technology landscape is transforming rapidly, driven by innovations aimed at enhancing efficiency and sustainability. One of the key advancements is the integration of IoT (Internet of Things) technologies into conveyor systems. According to a report by MarketsandMarkets, the IoT in the manufacturing sector is projected to grow at a CAGR of 26.9%, reaching a market size of $1.5 trillion by 2025. This integration allows real-time monitoring and predictive maintenance, minimizing downtime and maximizing throughput.

Another significant trend is the development of smart conveyor solutions that utilize AI and machine learning algorithms to optimize operation. Recent industry studies indicate that these intelligent systems can improve operational efficiency by up to 30%. Enhanced safety features, such as automatic shutoffs and obstacle detection, are also becoming standard, increasing workplace safety and reducing accident-related costs. With a projected reduction in operational expenses by 15%, companies investing in state-of-the-art conveyor technology are not only benefiting from improved performance but are also making strides towards sustainability in their operations.

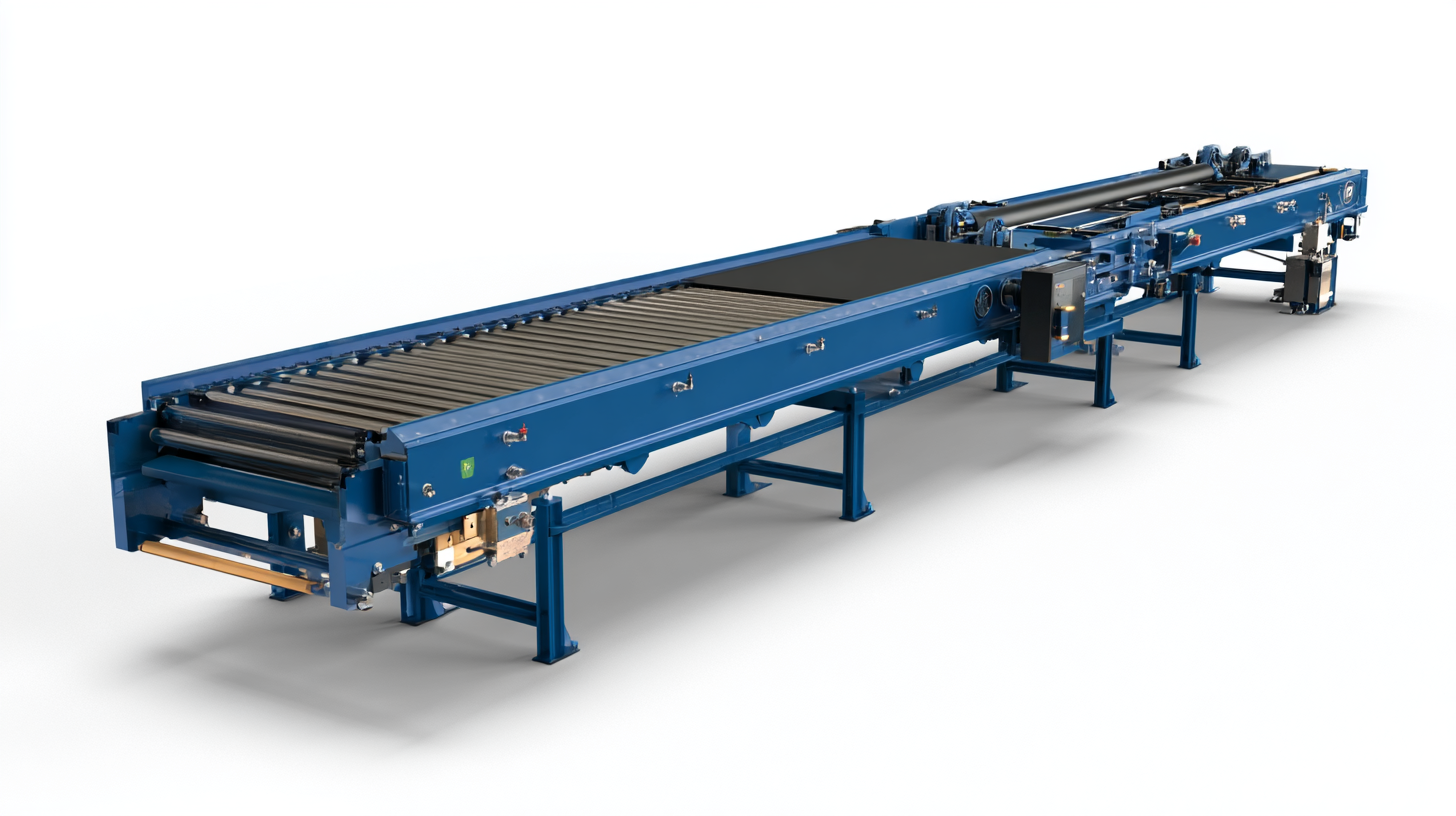

In the world of manufacturing and logistics, the selection of conveyor machines is crucial for optimizing efficiency and productivity. With various types available, such as belt conveyors, roller conveyors, and modular conveyors, it's essential to conduct a comparative analysis to determine what sets the best options apart. According to a report by MarketsandMarkets, the conveyor systems market is projected to reach $8.3 billion by 2025, indicating the growing importance of efficient material handling solutions in industrial settings.

Belt conveyors are often favored for their versatility and ability to handle a wide range of materials. They are particularly effective in moving bulk materials, making them ideal for industries like mining and agriculture. On the other hand, roller conveyors are renowned for their effectiveness in transporting heavier loads, which is why they are commonly used in warehouses and distribution centers. A study by IBISWorld highlights that roller conveyor systems reduce manual labor by up to 30%, showcasing their efficiency. Meanwhile, modular conveyors offer flexibility and scalability, allowing businesses to easily adapt to changing production demands.

Understanding the specific applications and advantages of each conveyor type is essential for businesses looking to enhance their operational workflows. Industry professionals should carefully assess their material handling requirements and the unique features of each conveyor option to identify the best fit for their operations. As the conveyor systems market continues to evolve, staying informed about technological advancements and trends will be key to making informed decisions.

In the competitive landscape of material handling, selecting a high-quality conveyor system is crucial for optimizing efficiency and productivity. According to recent industry reports, such as those from the Material Handling Industry Association (MHIA), engineers and plant managers report that a well-designed conveyor system can reduce operational costs by up to 30%. Thus, understanding what differentiates top-performing conveyor machines is essential for businesses looking to enhance their systems.

One of the key factors that sets the best conveyor systems apart is the quality of materials used in their construction. High-quality steel and advanced polymers are known to significantly increase durability and lifespan, leading to lower maintenance costs. For instance, conveyors made with corrosion-resistant materials can last up to 50% longer than those utilizing standard options, based on findings from the Conveyor Equipment Manufacturers Association (CEMA). Additionally, the integration of smart technology, such as sensors and IoT capabilities, allows for real-time monitoring and predictive maintenance, which studies suggest can reduce downtime by 20%, significantly impacting overall productivity. By prioritizing these features, businesses can ensure they choose a conveyor system that not only meets their current needs but also adapts to future demands.

This chart compares various factors that differentiate high-quality conveyor systems. The data below illustrates the average rating of superior conveyor systems based on key performance indicators.

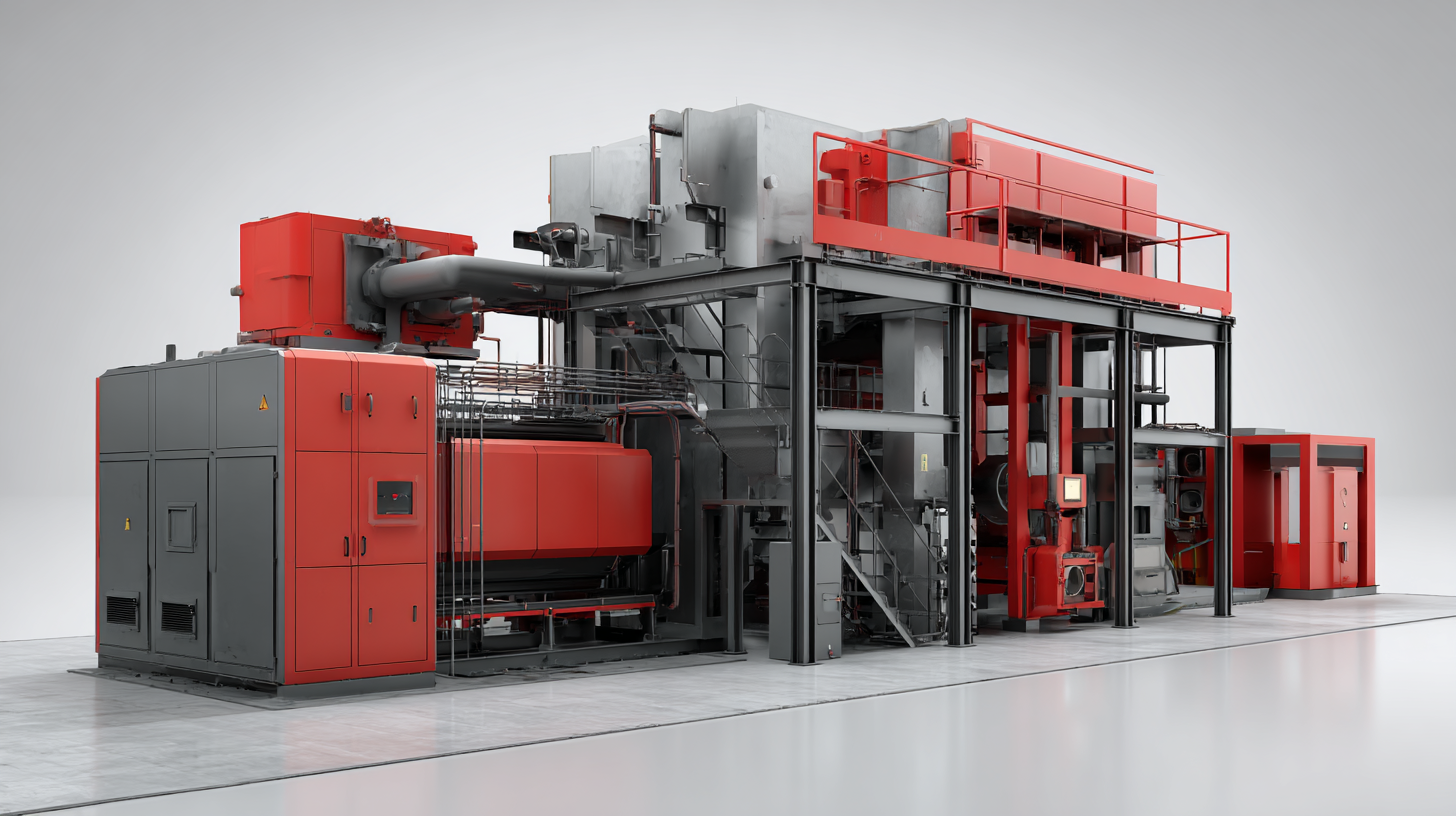

In the rapidly evolving world of manufacturing and logistics, automation is playing a crucial role in reshaping conveyor machines. As industries strive for greater efficiency and productivity, the integration of smart technology into conveyor systems has become a necessity. Automated conveyors can facilitate seamless operations by reducing manual labor, minimizing errors, and speeding up the movement of goods. This not only enhances overall productivity but also optimizes resource utilization, allowing companies to focus on more strategic tasks.

**Tip:** When considering an upgrade to automated conveyor systems, assess the specific needs of your operation. Look for conveyors that are adaptable and scalable to accommodate future growth or changes in product lines.

Moreover, with advancements in artificial intelligence and machine learning, conveyor systems can now analyze real-time data to predict maintenance needs and improve performance. Such proactive measures not only extend the lifespan of equipment but also decrease downtime, which is critical for maintaining competitive advantage. Automation not only streamlines processes but also transforms the way businesses operate.

**Tip:** Invest in conveyor systems with integrated monitoring technologies to leverage data analytics. This will enable you to make informed decisions and keep your production lines running smoothly.

| Type of Conveyor | Key Features | Automation Level | Applications | Future Trends |

|---|---|---|---|---|

| Belt Conveyor | Versatile, Low Maintenance | Moderate | Manufacturing, Warehousing | Smart Sensors, IoT Integration |

| Roller Conveyor | Flexible Layout, High Load Capacity | High | Order Fulfillment, Packaging | Autonomous Transport Systems |

| Chain Conveyor | Heavy-Duty, High Temperature Resistance | Medium | Automotive, Heavy Industries | Predictive Maintenance, AI |

| Magnetic Conveyor | Secure Transport, Ideal for Metal | High | Electronics, Metal Processing | Enhanced Safety Features |

| Bucket Conveyor | Vertical Transport, Bulk Handling | Low | Food Processing, Mining | Optimization Algorithms |

In the rapidly evolving world of manufacturing, conveyor machine design is experiencing innovative trends that promise to enhance efficiency and sustainability. One notable trend is the shift towards modular and flexible designs that accommodate various production processes. These systems allow manufacturers to adapt quickly to changing demands, ensuring that operations remain smooth and cost-effective. By investing in modular systems, companies can reduce downtime and improve overall productivity.

Another emerging trend is the integration of smart technologies into conveyor machines. With the advent of the Internet of Things (IoT), manufacturers can now monitor machine performance in real time, optimizing maintenance schedules and resource allocation. This predictive approach not only minimizes disruptions but also enhances energy efficiency, making operations greener.

Tips: When evaluating conveyor systems, look for features such as connectivity options and adaptability to different layouts. Additionally, consider investing in machines that incorporate energy-efficient technologies to reduce operational costs over time. Lastly, staying informed about the latest advancements in smart technologies can give your business a competitive edge in the market.