In the fast-paced world of logistics, Conveyor Systems Limited stands as a prominent player. Their innovations continuously reshape the industry. This sector demands sleek, efficient solutions, and Conveyor Systems Limited delivers on these promises. High-speed transport systems are now commonplace, yet aspects still warrant attention.

The year 2026 looks promising, with new technology on the horizon. Conveyor Systems Limited has embraced automation, yet some processes remain outdated. Users often report glitches or inefficiencies in certain models. These points reveal areas for improvement, despite overall advancements.

As companies seek ways to enhance productivity, examining Conveyor Systems Limited's offerings becomes essential. Innovations abound, like smarter tracking systems and eco-friendly designs. However, challenges persist, and customers need to voice their concerns. Balancing progress with functionality is key to future success.

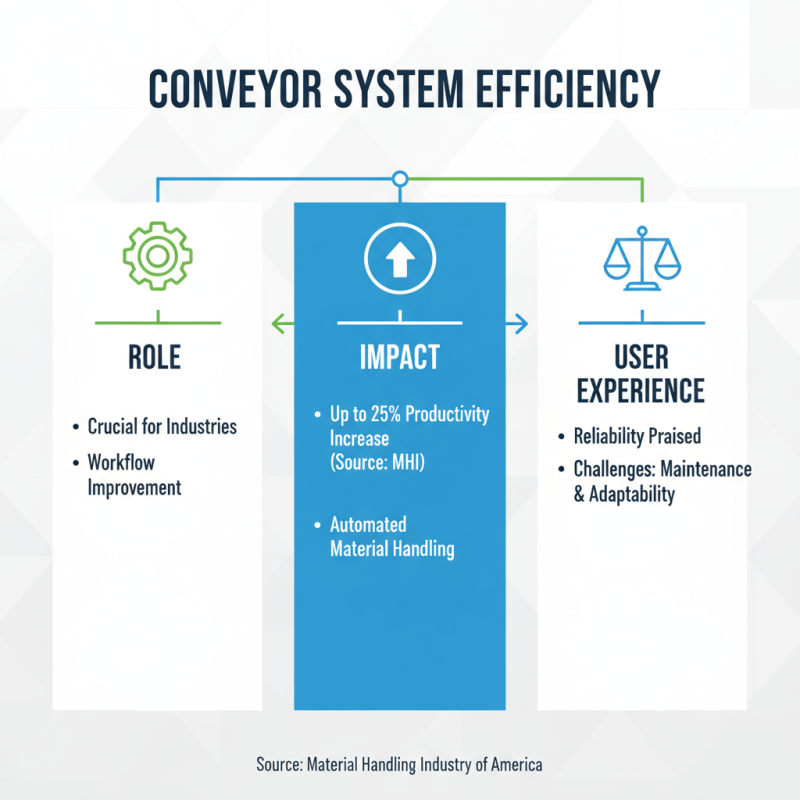

Conveyor systems play a crucial role in modern industries. They streamline transportation processes. This efficiency reduces labor costs significantly. Without these systems, operations may slow down. Workers would face increased manual tasks. This can lead to fatigue and safety issues.

Understanding conveyor systems is essential. They consist of various components such as belts, rollers, and drives. Each part must function well. Regular maintenance is often overlooked. Neglecting this can lead to unexpected breakdowns. Such disturbances can halt production and frustrate workers.

Moreover, innovation in conveyor technology is ongoing. New materials and designs aim to enhance efficiency. However, not every new system performs as expected. Some may encounter compatibility issues with older equipment. It's essential to evaluate these innovations carefully. Continuous improvement and adaptation are vital for maximizing benefits.

| System Type | Load Capacity (kg) | Speed (m/s) | Efficiency (%) | Innovative Features |

|---|---|---|---|---|

| Belt Conveyor | 150 | 1.5 | 85 | Smart tracking, energy efficiency |

| Roller Conveyor | 300 | 1.0 | 90 | Modular design, adjustable speed |

| Chain Conveyor | 500 | 0.8 | 88 | Heavy-duty, high durability |

| Screw Conveyor | 200 | 1.2 | 84 | Compact design, versatile use |

| Pneumatic Conveyor | 100 | 2.0 | 92 | Flexible routing, reduced dust |

Conveyor systems are vital in various industries. They enhance performance and efficiency by streamlining material handling. A well-designed system reduces manual labor and minimizes delays in production. Faster loading and unloading optimize workflow.

Key features of conveyor systems include speed and capacity. Adjustable speeds cater to different materials. This flexibility improves throughput. Operators can set speeds based on their needs. Another feature is modular designs, allowing easy reconfiguration. This adaptability is crucial, yet it can cause issues if not planned properly.

Despite the benefits, there are challenges. Maintenance can be a hurdle. Regular checks are necessary to avoid breakdowns. Employee training on system operation is also essential. Without proper knowledge, the efficiency gains can diminish. Balancing technology with human factors is a continuous process. Systems must evolve, reflecting changing demands in the market.

Innovations in conveyor technology are rapidly changing how industries operate. With the rise of automation, systems have become more efficient and flexible. Smart conveyor belts now incorporate sensors and AI. These technologies help in real-time monitoring and predictive maintenance. This minimizes downtime, but it can be tricky to implement. Traditional systems may struggle to adapt to these changes.

Another noteworthy trend is the use of modular designs. This makes installation easier and adjustments possible with minimal disruption. However, some environments may not benefit as expected. Custom solutions might be essential, but they can lead to complexity. Cost considerations may limit innovation for smaller companies.

Sustainability is also influencing conveyor systems. Eco-friendly materials are increasingly being used in production. Energy-efficient motors reduce operational costs. Yet, not every innovation is perfect. Companies often face challenges in balancing sustainability with performance. The path ahead requires careful planning and innovation.

In 2026, conveyor systems continue to evolve, offering new solutions. Many designs prioritize efficiency and safety. However, not all systems meet expected standards. Some user reviews reveal common issues, such as maintenance challenges and design flaws. It’s essential to look closely at customer feedback and performance data.

Comparative analyses show varied results across different systems. Factors like load capacity, speed, and energy efficiency can differ greatly. Some systems excel in high-speed environments, while others perform better with heavier materials. It’s vital to weigh these differences based on specific needs. Users may find that a detailed assessment leads to unexpected discoveries about compatibility and long-term costs.

While innovations are impressive, they come with a learning curve. Training is necessary for optimal operation. Moreover, the upfront investment often raises concerns. Are these systems worth the price? Buyers may need to rethink their priorities and long-term goals before making decisions. Critical evaluations are key to ensuring the chosen system aligns with operational demands and financial considerations.

The efficiency of conveyor systems plays a crucial role in various industries. Many companies report significant improvements in workflow after implementing these systems. According to industry research by the Material Handling Industry of America, automating material handling can increase productivity by up to 25%. However, user experiences can vary widely. Some have praised the reliability of modern systems; others have shared challenges with maintenance and adaptability.

Case studies often show unique insights. A manufacturing company decreased operational downtime by 15% after installing a tailored conveyor solution. Yet, not all feedback is positive. Users have pointed out issues with initial setup and integration with existing workflows. The complexity of these systems can lead to unforeseen challenges. While they may promise higher output, the learning curve can be steep. Companies need to prepare adequately to address this gap.

User feedback highlights the necessity for thorough training. Many operators felt unprepared when starting with new systems. With 30% of companies reporting frequent errors during initial use, this is a critical area for improvement. Addressing these issues through better user education could unlock the full potential of conveyor systems in the years to come.