In today’s fast-paced manufacturing environment, optimizing productivity is crucial for staying competitive, and Assembly Conveyor Systems play a pivotal role in achieving this. According to a recent report by the Material Handling Industry of America (MHIA), over 75% of manufacturers have implemented some form of conveyor system to streamline their operations, resulting in a 30% increase in efficiency on average. These systems not only enhance the speed and accuracy of assembly processes but also minimize labor costs and reduce product handling errors. With the global conveyor system market projected to reach $9.2 billion by 2025, understanding the various solutions available for maximizing the efficiency of Assembly Conveyor Systems is more important than ever for companies aiming to adapt to changing market demands and improve their operational workflows.

Assembly conveyor systems play a crucial role in improving productivity across various industries by optimizing workflows and reducing operational bottlenecks. According to a report by the Material Handling Industry of America (MHIA), companies that incorporate automated conveyor systems can experience a productivity increase of up to 30%. This enhancement is largely attributed to the seamless movement of materials between different stages of the assembly line, which minimizes manual handling and streamlines processes.

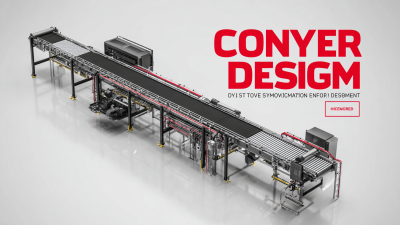

Understanding the fundamentals of assembly conveyor systems is essential for maximizing their effectiveness. These systems typically consist of modular components that can be customized based on specific production requirements. Research from the Institute of Packaging Professionals indicates that adaptable conveyor solutions can reduce overall cycle times by approximately 20%. This flexibility allows organizations to respond swiftly to changes in production demand, ultimately leading to a more efficient use of resources and improved output. By investing in modern conveyor systems, manufacturers can achieve not only enhanced productivity but also a significant return on investment.

| Dimension | Description | Impact on Efficiency |

|---|---|---|

| Belt Speed | Rate at which the conveyor moves products | Higher speeds can reduce cycle time but may lead to defects if too fast. |

| Load Capacity | Maximum weight the conveyor can handle | Ensures optimal throughput without breakdowns. |

| Maintenance Schedule | Regular check-ups and part replacements | Prevents downtime and extends conveyor lifespan. |

| Integration with Robotics | Use of robots for loading/unloading | Increases automation and reduces labor costs. |

| Sensor Technology | Use of sensors for monitoring flow | Enhances tracking and error detection. |

Efficient assembly conveyor systems are vital for boosting performance on production lines, particularly as consumer demands rise. According to a recent study by the International Society of Automation, companies can enhance assembly line productivity by up to 30% through the implementation of automated conveyor solutions. Key features of these systems, such as adjustable speed controls and modular designs, allow manufacturers to tailor operations to specific product requirements and flow rates, ensuring optimal efficiency.

Additionally, the integration of IoT technology into conveyor systems can provide real-time monitoring and analytics, which facilitates better decision-making and minimizes downtime. A report from the Association for Manufacturing Technology indicates that predictive maintenance powered by IoT can reduce unplanned downtime by as much as 20%, leading to significant cost savings. By focusing on these critical features, businesses can not only streamline their assembly processes but also foster a proactive approach to maintenance and production optimization.

In today's fast-paced manufacturing environment, implementing lean manufacturing principles in the design of assembly conveyor systems is crucial to enhancing operational efficiency. According to a report by the Lean Enterprise Institute, organizations that adopt lean practices can achieve a 30% reduction in lead times and a 25% decrease in costs. By integrating these principles into conveyor system design, manufacturers can streamline workflows, reduce waste, and improve product quality.

One of the key aspects of lean design is the emphasis on continuous flow, which can be effectively achieved through strategically designed conveyor systems. For instance, a case study from the Institute of Industrial Engineers revealed that companies utilizing modular conveyor systems experienced a 50% increase in throughput. Such systems allow for adaptable layouts that can respond to changing production needs while minimizing the use of space and materials. Furthermore, incorporating real-time monitoring and feedback mechanisms can significantly enhance productivity, enabling teams to identify bottlenecks and inefficiencies quickly.

By focusing on lean manufacturing principles, businesses can not only optimize their assembly conveyor systems but also create a culture of continuous improvement. Research from McKinsey & Company indicates that companies implementing lean strategies see an improvement in employee engagement, which is tied to a 20% increase in overall efficiency. This holistic approach ensures that manufacturing operations are not just efficient at the technical level but also foster a committed workforce dedicated to achieving excellence.

In today's fast-paced manufacturing environment, leveraging advanced automation technologies in assembly conveyor systems can significantly enhance efficiency and productivity. These systems not only streamline workflows but also minimize labor costs and reduce errors. Incorporating state-of-the-art sensors and robotics allows for real-time monitoring and adjustment of assembly processes, ensuring that operations run smoothly and efficiently.

Tip: Consider integrating IoT (Internet of Things) devices within your conveyor systems. These smart technologies provide data analytics that can optimize production schedules and predict maintenance needs, preventing costly downtime.

Another effective strategy is to utilize modular conveyor systems that can be easily reconfigured as production demands change. This flexibility allows manufacturers to quickly adapt to new product lines or changes in assembly processes without extensive downtime or re-installation costs.

Tip: Regular training for employees on the latest automation technologies can empower your workforce to utilize the systems to their fullest potential. This ensures that everyone is aligned with the technology and can contribute to a seamless assembly process.

Regular maintenance practices are crucial to ensure the longevity and efficiency of assembly conveyor systems. These systems play a vital role in various industries, enhancing productivity and workflow. By implementing routine checks, you can catch potential issues early, minimizing downtime and costly repairs.

One effective tip is to develop a maintenance schedule that includes regular inspections of components such as belts, rollers, and motors. Additionally, lubricating moving parts and ensuring proper tension can greatly enhance performance. Keeping a detailed maintenance log not only helps track the system's condition but also provides valuable insights for future improvements.

Another vital practice is to invest in predictive maintenance technologies. Utilizing data analytics and machine learning can help detect anomalies before they become significant problems. This proactive approach not only extends the lifespan of conveyor systems but also optimizes their efficiency, aligning with broader industry trends of enhancing operational performance through innovative maintenance solutions.