In today's rapidly evolving industrial landscape, businesses are continually seeking innovative ways to enhance operational efficiency and reduce costs. Conveyor technology has emerged as a pivotal factor in achieving these goals, with recent reports indicating that companies can improve productivity by up to 50% through the implementation of advanced conveyor systems. A study by the International Federation of Robotics highlights that automated conveyor solutions can reduce labor costs by approximately 30%, allowing organizations to allocate resources more effectively.

Furthermore, advancements in conveyor technology, such as smart sensors and AI integration, provide real-time data analytics that enable companies to streamline processes and minimize downtime. As industries strive for greater efficiency, understanding how to leverage these technological advancements in conveyor systems is essential for maintaining a competitive edge in the marketplace.

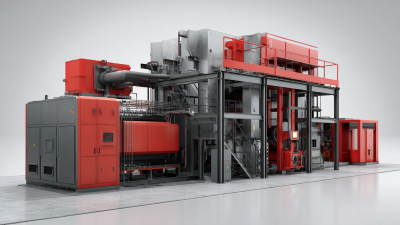

Conveyor technology plays a pivotal role in enhancing business efficiency by streamlining workflows and minimizing manual handling. Understanding the fundamentals of conveyor systems is crucial for businesses looking to optimize their operations. These systems transport materials seamlessly across various processes, reducing downtime and improving overall productivity. By integrating advanced features such as automation and real-time monitoring, companies can ensure that their conveyor systems operate at peak efficiency, adapting to dynamic production needs.

The role of conveyor technology extends beyond just movement; it encompasses the entire operational ecosystem. For instance, incorporating sensors and high-quality materials in conveyor design can significantly decrease maintenance costs and increase lifespan. Additionally, modern conveyor systems can be customized to fit specific operational needs, allowing businesses to optimize space and resource allocation. By harnessing these advancements, companies can achieve higher throughput and responsiveness, ultimately driving growth and enhancing their competitive edge in the market.

Recent advancements in conveyor technology have revolutionized the way businesses optimize their operations for enhanced productivity. Innovative conveyor systems are being designed with automation and smart features that minimize manual handling and streamline processes. Automated guided vehicles (AGVs) and robotic sorting systems integrated with conveyor belts are now commonplace, enabling companies to efficiently manage the flow of materials with minimal human intervention.

Furthermore, the use of data analytics and IoT (Internet of Things) in conveyor systems allows for real-time monitoring and maintenance. Predictive maintenance tools can help identify issues before they escalate, reducing downtime and improving overall system reliability. Additionally, modular designs enable easy customization of conveyor layouts, permitting businesses to adapt quickly to changing production demands and space constraints. These innovations not only enhance operational efficiency but also contribute to significant cost savings and improved safety in the workplace.

This chart represents the improvements in productivity and reductions in operational costs as a result of advancements in conveyor technology over four quarters. The increase in productivity highlights the effectiveness of the latest conveyor systems, while the decrease in costs showcases enhanced operational efficiency.

The integration of smart technology into conveyor systems has revolutionized the way businesses operate, particularly in industries like manufacturing and logistics. According to a recent report by the International Journal of Advanced Manufacturing Technology, companies that implemented smart conveyor systems reported a 25% increase in operational efficiency and a 30% reduction in downtime. These advancements are primarily driven by real-time monitoring capabilities, which allow for immediate feedback on system performance and product flow.

Smart conveyors equipped with IoT sensors can detect anomalies in real time, enabling maintenance teams to address issues before they escalate. A study by the Material Handling Industry of America (MHIA) found that predictive maintenance could save companies up to 12% in maintenance costs while boosting equipment lifespan by 20%. This level of monitoring not only enhances productivity but also helps businesses maintain smoother operations, ultimately leading to improved service delivery and customer satisfaction. As these technologies continue to evolve, companies that harness their potential stand to gain a significant competitive advantage in an increasingly demanding marketplace.

| Dimension | Value |

|---|---|

| System Type | Automated Conveyor |

| Average Speed | 50 ft/min |

| Monitoring Frequency | Every 5 seconds |

| Downtime Reduction | 30% |

| Integration Cost | $15,000 |

| Return on Investment (ROI) | 200% |

| Energy Efficiency Improvement | 25% |

| Real-time Monitoring Features | Speed, Load, Maintenance Alerts |

To effectively measure the efficiency gains of conveyor technology advances, businesses should focus on identifying and tracking key performance indicators (KPIs). One of the most critical KPIs for conveyor systems is the throughput rate, which quantifies the amount of product successfully moved through the conveyor within a specific time frame. Tracking throughput allows companies to assess the effectiveness of their conveyor systems and make necessary adjustments to optimize performance.

Another important KPI is downtime, which measures the time the conveyor system is not operational due to maintenance or malfunctions. By reducing downtime, businesses can significantly increase overall productivity. Additionally, evaluating the energy consumption of conveyor systems provides insight into operational efficiency and cost savings. By monitoring these KPIs, companies can make data-driven decisions that enhance their conveyor technology and maximize overall business efficiency.

Implementing best practices for maintenance and optimization of conveyor operations is crucial to boosting business efficiency and minimizing downtime. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), improper maintenance can lead to up to 25% of operational downtime, significantly impacting productivity. To combat this, regular preventive maintenance programs should be established, focusing on lubrication, alignment, and inspections. By investing in condition monitoring technologies, businesses can predict failures before they happen, allowing for maintenance activities to be planned without interrupting the flow of operations.

Furthermore, enhancing conveyor systems with automation and smart technologies can lead to substantial efficiency gains. A study by AMR Research indicates that companies that adopted advanced conveyor systems reported a reduction in energy consumption by up to 30%. Implementing real-time data analytics and IoT solutions enables operators to gather insights on conveyor performance, leading to timely adjustments and optimizations. This not only enhances operational effectiveness but also extends the lifecycle of conveyor equipment, ultimately resulting in significant cost savings and improved service delivery.