In the rapidly evolving manufacturing and logistics landscape, optimizing the Tire Conveyor and Storage Line has become paramount for achieving maximum efficiency. According to recent industry reports, the global tire production market is projected to reach $284 billion by 2025, highlighting the critical need for efficient material handling systems in tire manufacturing and distribution facilities. Effective management of tire conveyor and storage lines not only reduces operational costs but also significantly enhances throughput and overall productivity.

Research has shown that implementing advanced technologies and best practices in the design of Tire Conveyor and Storage Lines can lead to efficiency improvements of up to 30%. Techniques such as automation, real-time tracking, and smart inventory management systems are being increasingly adopted to streamline operations and minimize downtime. By focusing on optimizing the tire conveyor processes, manufacturers can better respond to market demands while maintaining stringent quality control measures, ultimately leading to improved customer satisfaction and business growth. In this article, we will explore practical strategies and insights for optimizing tire conveyor and storage lines, ensuring that manufacturers are well-equipped to meet the challenges of the future.

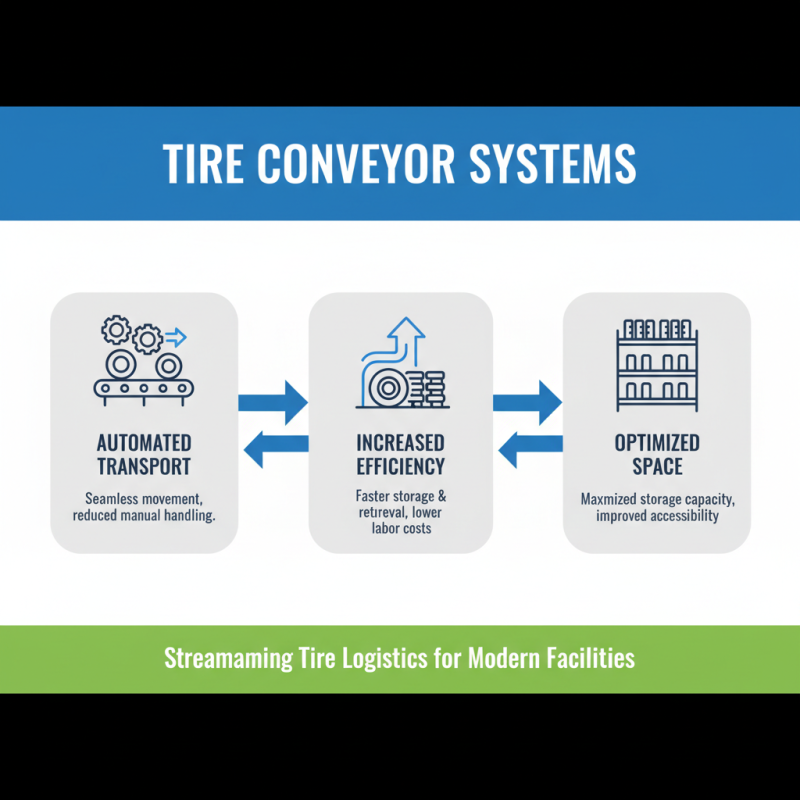

Tire conveyor systems play a crucial role in enhancing the efficiency of tire storage and movement within manufacturing and distribution environments. These systems are designed to facilitate the seamless transport of tires from one area to another, reducing manual handling and minimizing the associated risks of damage and labor costs. By implementing an optimized tire conveyor system, facilities can significantly increase their storage capabilities while ensuring that the tires are easily accessible when needed. This integration not only streamlines operations but also contributes to better space utilization within warehouses.

In addition to transportation efficiency, the configuration of tire conveyor systems directly impacts overall productivity. Various factors, such as conveyor layout, speed, and sorting technology, can be adjusted to meet specific operational needs. For instance, incorporating automated sorting features can lead to quick retrieval and dispatch of tires, minimizing idle time and enhancing workflow. Moreover, proper maintenance practices should be instituted to ensure the longevity of the conveyor system, preventing downtime that could disrupt the entire storage line. Emphasizing these elements will create a synergy between tire handling and storage processes, paving the way for maximum operational efficiency.

The performance of tire conveyor systems largely hinges on several key factors that can significantly enhance operational efficiency. One of the most critical elements is the design and layout of the conveyor system itself. A well-planned conveyor design minimizes material handling time and maximizes throughput. Optimizing the height, angle, and contour of the conveyor can reduce friction and wear, ensuring smoother movement of tires along the line. Additionally, integrating advanced technology, such as sensors and automated controls, can streamline processes, allowing for real-time monitoring and adjustments to enhance efficiency and responsiveness to demand fluctuations.

Another essential factor influencing conveyor performance is the maintenance regime in place. Regular inspections and proactive maintenance can mitigate unexpected breakdowns and downtime, ensuring continuous operation. Additionally, the choice of conveyor materials plays a crucial role; selecting high-durability components can extend the lifespan of the conveyor and reduce the frequency of replacements. Training personnel in best practices for operating and maintaining the system further contributes to optimizing performance, as knowledgeable staff can identify potential issues early and implement effective solutions. By focusing on these key elements, companies can significantly enhance the efficiency of their tire conveyor and storage lines.

| Key Factor | Description | Impact on Efficiency (%) | Optimal Range |

|---|---|---|---|

| Conveyor Speed | The rate at which tires move along the conveyor. | 15% | 30-50 m/min |

| Load Capacity | Maximum weight the conveyor can handle. | 20% | 500-1000 kg |

| Maintenance Schedule | Regular checks and servicing to avoid breakdowns. | 25% | Every 3-6 months |

| Tire Alignment | Proper positioning of tires on the conveyor. | 10% | Within ±1 degree |

| Energy Efficiency | Power consumption per unit of output. | 30% | < 1 kWh/tire |

The optimization of tire conveyor systems is crucial for enhancing operational efficiency in manufacturing and logistics. Innovative technologies such as advanced automation and real-time monitoring are pivotal in transforming traditional conveyor systems. According to a recent industry report by the Conveyor Equipment Manufacturers Association (CEMA), implementing smart sensors can lead to a 20% reduction in operational downtime by enabling predictive maintenance. These sensors track wear and tear, ensuring that potential issues are resolved before they lead to significant disruptions.

Incorporating artificial intelligence (AI) into tire conveyor systems also profoundly impacts efficiency. A study from the International Journal of Industrial Engineering estimates that AI-driven systems can improve throughput by up to 30% by optimizing routing and minimizing bottlenecks. These technologies analyze vast amounts of operational data to make real-time adjustments, ensuring that tire movement is as streamlined as possible. Additionally, integrating automated guided vehicles (AGVs) alongside conveyor systems can enhance flexibility, allowing for dynamic adjustments based on real-time workload demands. This synergy not only maximizes space utilization in storage areas but also increases overall productivity in tire handling processes.

Maintaining optimal efficiency in tire conveyor and storage lines is crucial for manufacturers aiming to enhance productivity. Industry reports indicate that regular maintenance can lead to a reduction in downtime by 30%, which is essential for maximizing throughput. Key best practices include scheduled inspections and timely replacements of worn components. According to a study published by the International Rubber Study Group, proactive maintenance can increase conveyor system lifespan by up to 40%, highlighting the importance of a systematic approach to equipment care.

In addition to maintenance, operator training plays a vital role in the effective operation of tire storage lines. A well-trained team can significantly minimize errors and improve the speed of operations. Research has shown that organizations that invest in operator training programs can see a 25% increase in overall efficiency. Incorporating real-time monitoring and automated alerts for performance metrics further enhances operational capabilities, allowing for quick responses to any deviations from optimal performance.

By focusing on these best practices, manufacturers can ensure that their tire conveyor and storage lines operate at peak efficiency and contribute effectively to overall business goals.

Upgrading tire conveyor solutions can significantly enhance operational efficiency and reduce long-term costs. As businesses assess the cost-effectiveness of these upgrades, several factors come into play. Initially, the longevity and durability of components can lead to fewer maintenance requirements, translating to lower labor and material costs over time. High-efficiency motors and advanced control systems enable smoother operations and reduced energy consumption, making them pivotal in evaluating the return on investment.

Furthermore, integrating smart technology into tire conveyor systems can streamline processes and optimize workflow. Real-time monitoring allows for better decision-making, minimizing downtime and ensuring that resources are used effectively. The data gathered from these systems not only informs maintenance schedules but also helps in forecasting future needs, ultimately contributing to a more sustainable operational model. The initial costs of upgrading may appear significant, but the long-term savings and enhanced productivity make these solutions a strategically sound investment.