In the evolving landscape of Conveyor Manufacturing, staying updated is essential. Industry expert David Smith once noted, “Innovation drives success in conveyor systems.” This statement resonates deeply as businesses navigate contemporary challenges.

Today, top trends shape how manufacturers design and implement conveyor systems. Automation, for instance, plays a crucial role in enhancing efficiency. However, many companies may overlook the importance of manual processes still in place. A balance is required to ensure effectiveness without losing human touch.

Sustainability is another pressing issue in Conveyor Manufacturing. Companies are investing in eco-friendly materials and practices. Yet, some struggle to integrate these changes seamlessly. The journey is not straightforward, and manufacturers must adopt a reflective mindset as they adapt to these trends. Embracing innovation while addressing existing gaps will define the future of conveyor systems.

Emerging technologies in conveyor manufacturing are revolutionizing the industry. Automated systems are now being integrated with artificial intelligence and machine learning. Reports indicate that 45% of manufacturers are utilizing AI to optimize conveyor operations. These technologies enable predictive maintenance and reduce downtime, enhancing efficiency.

The rise of IoT has transformed conveyor systems into smart networks. Sensors embedded in the conveyors collect real-time data. This data helps in monitoring performance and diagnosing issues before they escalate. A recent study showed that manufacturers using IoT saw a 30% increase in output.

However, this transition isn't without its challenges. Many companies face difficulties in implementing these advanced technologies. Employees might require retraining or upskilling. Overcoming resistance to change can be complex. While the benefits are clear, the journey toward full integration remains a work in progress. Continuing to adapt and refine these technologies will be essential for future growth.

| Trend | Description | Impact on Industry | Adoption Rate |

|---|---|---|---|

| Automation Integration | Incorporating robotics and AI into conveyor systems to enhance efficiency. | Increased productivity and reduced labor costs. | 75% |

| Smart Sensors | Utilization of IoT sensors for real-time monitoring. | Enhanced maintenance and reduced downtime. | 60% |

| Sustainability Practices | Adoption of eco-friendly materials and processes. | Improved corporate responsibility and reduced environmental impact. | 80% |

| Modular Conveyor Systems | Flexible designs that accommodate varying production needs. | Faster adjustments and scalability in production. | 70% |

| Data Analytics | Using data to optimize operational efficiency. | Informed decision-making and performance improvement. | 65% |

| Ergonomic Design | Systems built with operator safety and comfort in mind. | Reduced injury rates and improved workplace satisfaction. | 55% |

| Virtual Reality Training | Using VR technology for training workers on conveyor operations. | Improved training efficiency and reduced errors. | 40% |

| Advanced Materials | Incorporation of lightweight, durable materials for belts. | Improved energy efficiency and longer lifespan of equipment. | 65% |

| Cloud-based Solutions | Integration of cloud technology for centralized data management. | Enhanced accessibility and easier collaboration. | 50% |

| Flexible Automation | Adaptive systems that can handle various products without extensive reconfiguration. | Increased operational agility and reduced costs. | 45% |

Sustainability is becoming essential in conveyor production. Manufacturers are increasingly focusing on reducing their carbon footprint. They are adopting eco-friendly materials, which can be recycled more easily. This shift helps minimize waste and promotes a circular economy. Renewable resources are often prioritized, leading to innovations in design.

Energy efficiency is another critical area for improvement. Many production processes now use less energy, which is a positive step. However, not all manufacturers have made significant strides in this area. Some still rely on outdated machinery that consumes excessive power. This raises questions about their commitment to sustainability.

Water usage in production is also under scrutiny. While some companies are implementing better practices, others continue to waste water. This inconsistency reflects a broader issue in the industry. While goals are set for greener practices, the execution can often fall short. Awareness and action must go hand in hand for meaningful change.

Automation has transformed the manufacturing landscape, especially in conveyor systems. These systems are now smarter and more efficient. Sensors and software enhance functionality. They allow real-time monitoring and data collection. This leads to increased productivity and safety. Operators can quickly identify issues before they escalate.

The integration of robotics with conveyor systems is significant. Robots can handle complex tasks alongside conveyor belts. They pick, place, and package with precision. However, this shift can create a gap. There is a need for skilled workers to manage these automated systems. Training is essential. Companies face challenges in sourcing qualified personnel.

Another area of concern is the cost of implementation. While automation can save money long-term, initial investments can be high. There are decisions to be made regarding the best technologies. Each business has unique needs and budgets. It's essential to evaluate the potential ROI carefully. Balancing innovation with practicality remains a continual reflection for manufacturers.

In recent years, customization in conveyor manufacturing has surged. A study shows that 75% of manufacturers are focusing on tailored solutions to meet unique operational needs. This shift allows companies to optimize efficiency. Modular designs support this customization trend. They enable manufacturers to easily swap out components, saving time and resources.

The flexibility of modular systems attracts many businesses. Customization allows for specific configurations. Reports indicate that modular conveyor systems can reduce installation time by 30%. However, customization can also lead to complexities. Companies often struggle with integration. It's essential to balance tailored solutions with standardization.

Customization should not come at the expense of efficiency. Some businesses overspend on unique designs that don’t produce the intended results. A focus on the broader picture can prevent costly mistakes. As the market evolves, understanding these trends is crucial for success. It's a delicate dance between innovation and practicality.

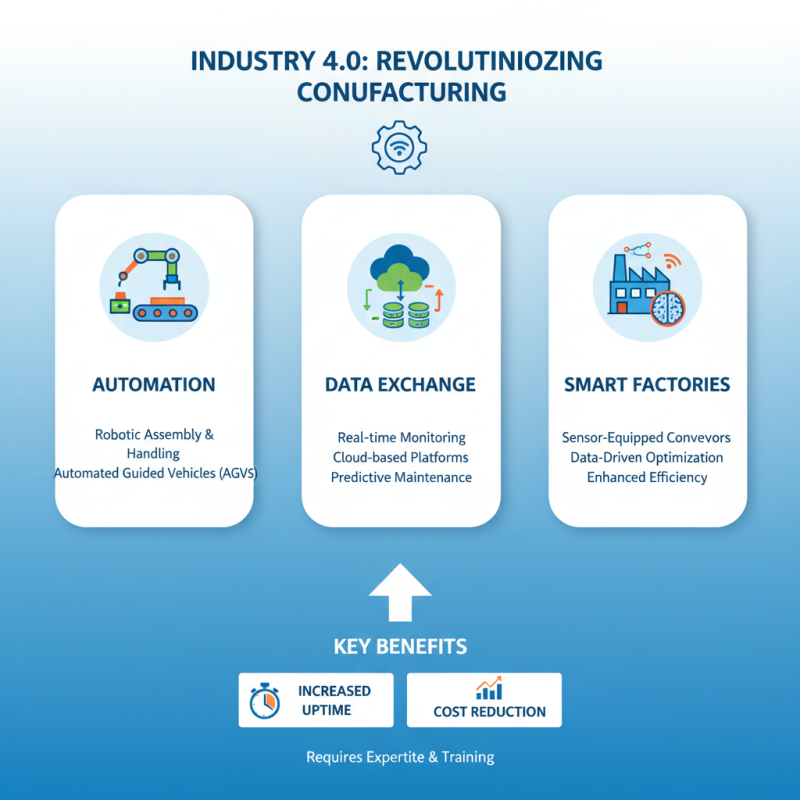

Industry 4.0 is redefining conveyor manufacturing processes. Automation and data exchange are key components. Smart factories leverage real-time data to optimize operations. Conveyors equipped with sensors can track performance metrics instantly. This technology enhances efficiency but requires a deep understanding of the machinery.

Adoption of robotics is another important aspect. Robots work alongside conveyor systems to streamline production. However, integrating these systems can be challenging. There is a learning curve. Employees must adapt to new technologies. Not all workers embrace change easily. Training becomes critical, yet difficult to implement effectively. Companies must invest in ongoing education.

Data analytics plays a vital role as well. Analyzing production data helps identify bottlenecks. Teams can make informed decisions to improve workflows. Yet, many companies still struggle with data integration. Systems often work in silos, leading to missed opportunities. Without effective collaboration, the full benefits of Industry 4.0 remain elusive.