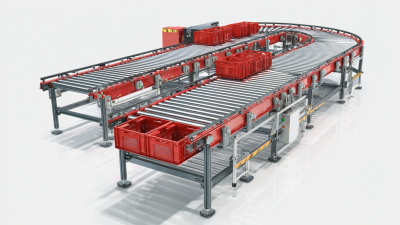

In today's fast-paced global market, efficiency and productivity are paramount, and one of the key innovations driving this transformation is Automation Conveyor Systems. These systems are revolutionizing supply chains by seamlessly integrating technology with logistics, enabling businesses to optimize their operations more than ever before. From enhancing workflow to reducing labor costs, automation conveyor systems offer numerous benefits that cater to the diverse needs of industries worldwide.

This ultimate guide will explore seven cutting-edge automation conveyor systems that are not only reshaping the landscape of supply chain management but also setting new standards in operational excellence. Whether you are a seasoned logistics professional or a newcomer to the field, understanding these transformative technologies is essential for gaining a competitive edge in the global marketplace. Join us as we delve into the future of supply chain automation and its impact on businesses around the globe.

The implementation of conveyor automation systems in global supply chains presents several key challenges that companies must navigate to achieve optimal efficiency. According to a report by McKinsey, 45% of supply chain executives identified integrating new automation technologies into existing systems as a primary hurdle. This integration often requires not only a substantial investment in technology but also substantial changes in workforce training and processes. Many companies find that their employees must adapt to new operational paradigms, which can lead to resistance and delays in deployment.

Another significant challenge lies in measuring the return on investment (ROI) for automation systems. A study from Gartner indicated that nearly 70% of organizations struggle with evaluating the financial benefits of automation initiatives. This difficulty can stem from the complex nature of supply chains, where potential cost savings are often intertwined with numerous variable factors. Proper data analytics and predictive modeling are essential to convincingly illustrate the long-term benefits these systems can bring, paving the way for informed decision-making. With these challenges acknowledged, companies can better prepare for the successful implementation of conveyor automation systems, enhancing their overall supply chain efficiency.

| Conveyor System Type | Key Features | Common Challenges | Implementation Cost ($) | Expected ROI (%) |

|---|---|---|---|---|

| Belt Conveyor | Flexible configuration, suited for bulk materials | Wearing parts, space constraints | 5,000 - 50,000 | 20 - 40 |

| Roller Conveyor | Gravity and powered options | Lack of adaptability, heavy loads can cause damage | 8,000 - 60,000 | 25 - 45 |

| Chain Conveyor | Heavy-duty, suitable for pallets | Higher maintenance frequency | 10,000 - 70,000 | 15 - 35 |

| Magnetic Conveyor | Designed for ferrous metal components | Limited to magnetic materials | 15,000 - 80,000 | 30 - 50 |

| Pneumatic Conveyor | Transporting bulk materials with air pressure | Dust, noise pollution, complex design | 12,000 - 100,000 | 18 - 32 |

| Vibrating Conveyor | Gentle handling of bulk materials | Wear and vibration management | 20,000 - 90,000 | 20 - 38 |

| Zipper Conveyor | Vertical movement of products | Effective space usage but high installation cost | 25,000 - 150,000 | 22 - 41 |

The global landscape of supply chain management is undergoing a significant transformation driven by advancements in automation technologies. With the logistics automation market expected to grow from $88.09 billion in 2025 to an astonishing $212.81 billion by 2032, companies are keenly aware of the cost implications of adopting conveyor automation systems. These systems can streamline processes, reduce labor costs, and enhance efficiency in warehousing and distribution centers, ultimately leading to increased profitability.

As e-commerce and warehouse construction exhibit signs of recovery following the pandemic slump, there is a renewed focus on automation tools that can elevate operational capabilities. The demand for robust, automated conveyor systems reflects a strategic shift towards resilience and responsiveness in supply chains. Furthermore, predictive maintenance technologies are becoming integral to the retail sector, ensuring that equipment operates optimally and reducing downtime. This proactive approach not only safeguards investments but also contributes to long-term sustainability within Supply Chain Management, enhancing overall competitiveness in a rapidly evolving market.

Downtime due to conveyor malfunctions can have a significant impact on production lines, causing delays and increasing operational costs. According to a report from the Institute of Industrial Engineers, equipment downtime can account for up to 20% of total manufacturing time. Conveyor systems are essential for streamlining the movement of goods; however, when they fail, the ripple effects can halt entire production processes. In fact, a study by the Manufacturing Institute revealed that unplanned downtime can result in losses exceeding $50 billion annually across U.S. manufacturing, highlighting the critical nature of maintaining reliable conveyor systems.

Moreover, the Cost of Poor Quality (COPQ) framework emphasizes that downtime not only affects production rates but also impacts product quality. When a conveyor system malfunctions, the inefficiency it creates can lead to increased waste, extended lead times, and customer dissatisfaction. For instance, a survey conducted by the Material Handling Industry (MHI) found that 87% of manufacturers experienced quality-related issues directly linked to their conveyor operations. Investing in automation and predictive maintenance solutions can thus not only mitigate these issues but also foster a more resilient supply chain capable of adapting to unexpected challenges and demand variations.

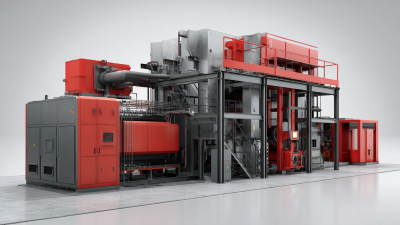

The integration of conveyor systems into existing logistics frameworks presents multifaceted complexities that organizations must navigate to achieve efficient supply chain automation. According to recent industry reports, advanced conveyor technologies can reduce operational costs by up to 30% and improve throughput efficiency by 20%. Evaluating these systems requires a deep understanding of the current logistical landscape and the adaptability of legacy systems to modern automation solutions, such as the semi-mobile in-pit crusher concept which utilizes mathematical optimization for efficiency.

Moreover, the potential of energy geo-structures and their synergy with conveyor systems presents an opportunity for integrating renewable energy sources in supply chains. Research indicates that implementing such infrastructure can significantly decrease energy consumption associated with traditional conveyor systems. As organizations look to modernize their operations while maintaining sustainability, the challenge lies in effectively evaluating and integrating these advanced conveyor systems, ensuring that they complement existing logistical frameworks without causing significant disruptions. This necessitates strategic change management, drawing upon frameworks like Kotter's Change Leadership Model, which provides a structured approach to navigating the transformation in logistics automation.

As the global logistics automation market is set to surge from $88.09 billion in 2025 to a staggering $212.81 billion by 2032, the conversation surrounding labor concerns in automation is more relevant than ever. The scarcity of skilled labor has been exacerbated in industries such as baking and snack production, where fewer workers are willing to engage in manual tasks like moving pans. Automation technology, particularly through intelligent conveyor systems, presents an effective solution to these labor challenges. Not only does it alleviate the burden on human workers, but it also enhances operational efficiency—an essential factor in an economy grappling with frequent supply chain disruptions.

Recent surveys reveal a profound shift in worker preferences, with 75% of warehouse employees indicating they would consider leaving their current jobs for positions that offer automation and technology-enhanced work environments. This inclination underscores a vital trend where workers are seeking jobs that leverage advanced technology, thereby changing the landscape of labor in modern warehouses. In response to driver shortages and environmental concerns, countries like Japan are, for instance, implementing automated cargo transport corridors like the proposed "conveyor belt road" between Tokyo and Osaka. Such advancements are not only crucial for addressing labor shortages but also key to reducing emissions and creating sustainable supply chains.

This bar chart illustrates various labor impact factors associated with automation in conveyor systems. Significant job displacement is observed at 60%, while job creation, although present, is at a lower 15%. The need for skill upgradation is crucial at 25%, with job satisfaction and employment rate being less affected, featured at 10% and 5%, respectively.